2 influence of temperature changes – VEGA VEGADIF 65 Chemical seal CSB User Manual

Page 6

6

3 Planning instructions for isolating systems

Chemical seal CSB • for VEGADIF 65

36133-EN-130417

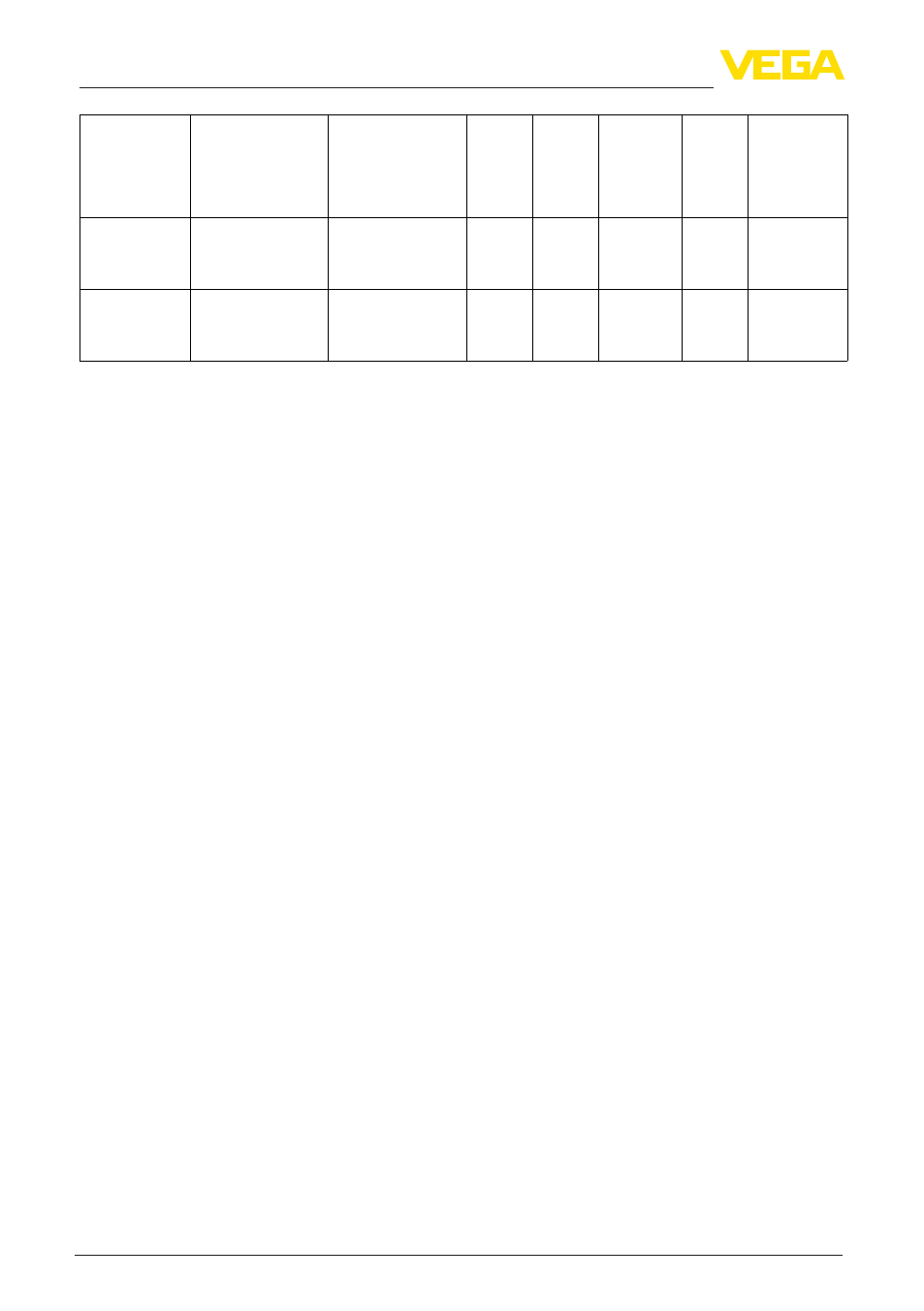

Filling oil

Permissible

product temper-

atures

Permissible

product tem-

peratures at

0.05 bar

abs

< p

< 1 bar

abs

Densi-

ty in g/

cm³

Vis-

cosity

in m

2

/

s•10

-6

Expan-

sion

coeffi-

cient 1/K

Cor-

rective

factor

for TK

Application

area

Halocarbon oil

KN21 (BAM

tested)

-40 … +150 °C (-

40 … +302 °F)

-40 … +80 °C (-

40 … +176 °F)

1.968

up to

20 °C

14

up to

20 °C

0.00086

0.83

For oxygen

and chlorine

applications

Med. white oil

KN92 (FDA

approved)

-10 … +250 °C

(+14 … +482 °F)

-10 … +160 °C

(+14 … +320 °F)

0.85

up to

20 °C

5.6

up to

40 °C

0.00065

0.63

suitable for

foodstuffs

The implemented filling oil also influences the TK

zero point

, the permis-

sible ambient temperature and the step response time of a chemical

seal. See also chapter "Influence of the temperature to the zero point"

and "Step response time".

The differential pressure transmitter also influences the temperature

application range, the TK

zero point

and the step response time of the iso-

lating system through the volume of its lateral flanges and its control

volume.

1)

3.2 Influence of temperature changes

The filling oil expands as the temperature increases. The additional

volume presses on the chemical seal. The more rigid the diaphragm,

the more it counteracts a volume change. The additional volume also

adds to the process pressure on the measuring cell and thus shifts

the zero point. The respective temperature coefficient "TK

Process

" is

listed in chapter "Dimensions and weights".

The following diagram shows the temperature coefficient depending

on the capillary length. The process temperature corresponds to the

calibration temperature. The temperature coefficients determined

from the diagram apply to silicone oil and the diaphragm material

316L. For other filling oil, these temperature coefficients have to be

multiplied with the correction factor for the TK of the respective filling

oil.

Differential pressure

transmitter

Influence of the tempera-

ture to the zero point

1)

The control volume is the volume that must be shifted in order to utilise the

complete measuring range.