6 supplement, 1 technical data, 2 dimensions and weight – VEGA VEGADIF 65 Chemical seal CSB User Manual

Page 18

18

6 Supplement

Chemical seal CSB • for VEGADIF 65

36133-EN-130417

6 Supplement

6.1 Technical data

Material

DIN/EN flanges are delivered in stainless steel 316L versions (material number 1.4435 or 1.4404).

Diaphragm

316L, Astelloy C276, Tantalum, Astelloy C276 with gold-

rhodium coating, 316L with 0.09 mm PTFE foil

Flanges

316L

Capillaries

316Ti

Protective hose for capillaries

304

Process conditions

Vessel pressure max.

see operating instructions manual of the respective

sensor

Process temperature max.

see operating instructions manual of the respective

sensor

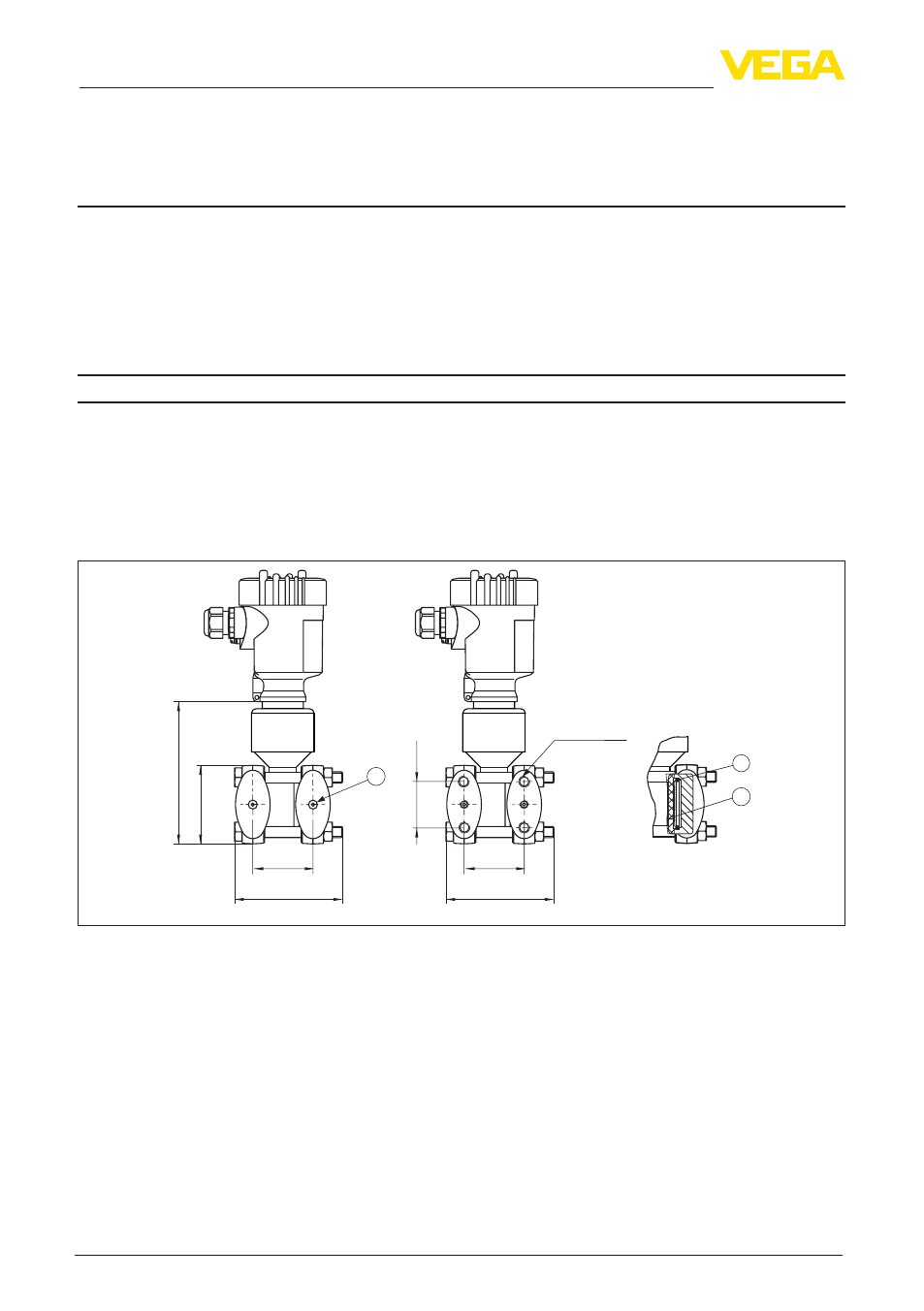

6.2 Dimensions and weight

2

3

72 mm (2.84")

128 mm (5.04")

98 mm

(3.94")

54 mm

(2.13")

+ –

41,3 mm (1.63")

98 mm

(3.94")

54 mm

(2.13")

+ –

7/16-20 UNF

M 10 (M12)

1

Fig. 15: left: Process fitting VEGADIF 65 prepared for chemical seal assembly. right: Position of the copper ring

seal

1 Chemical seal connection

2 Copper ring seal

3 Cup diaphragm

In the following charts, the typical values for the temperature coefficient "TK Process" are listed

apart from the dimensions. The values apply for silicone oil and the diaphragm material 316L. For

other filling oils, these must be multiplied with the TK corrective factor of the respective filling oil.

The stated nominal pressure applies to the chemical seal. The max. pressure for the complete

measuring system depends on the weakest element (with regard to pressure) of the selected com-

ponents.

In the charts you see the weights of the chemical seals. For the weight of the transmitter see also

"Dimensions and weights" in operating instructions VEGADIF 65.