3 dynamic behaviour of the chemical seals – VEGA VEGADIF 65 Chemical seal CSB User Manual

Page 10

10

3 Planning instructions for isolating systems

Chemical seal CSB • for VEGADIF 65

36133-EN-130417

– DRD DN 50 (65 mm), PN 25, 316L

0

1

2

3

4

5

6

7

8

9

10

–40

–20

0

20

40

60

80

Umgebungstemperatur

[°C

]

Kapillarlänge [m]

Gruppe F

erlaubter

Einsatzbereich

Fig. 7: Permissible ambient temperature range depending on the capillary

length for chemical seals of group F

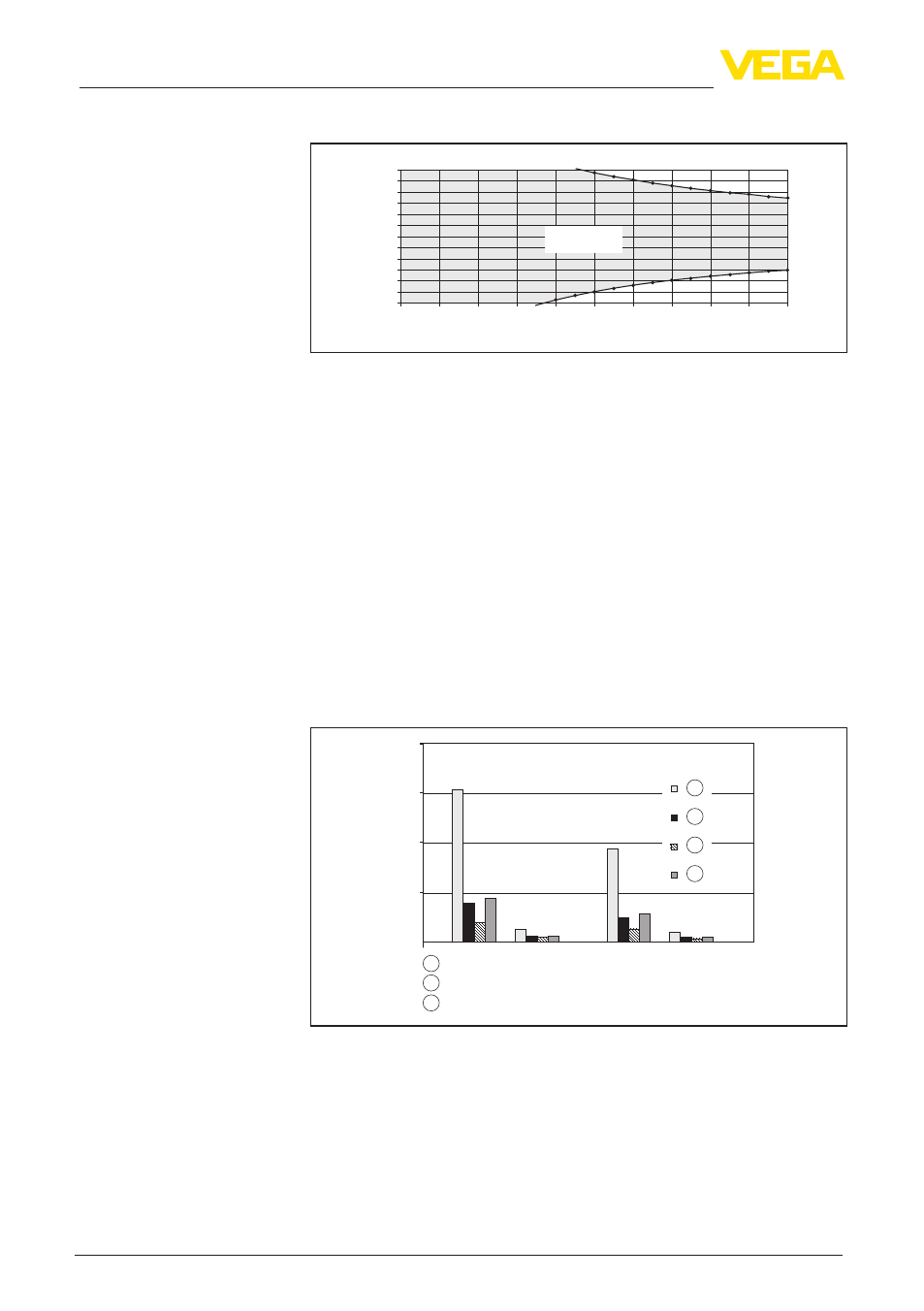

3.3 Dynamic behaviour of the chemical seals

The viscosity of the filling oil, the capillary length as well as the inner

diameter influence the frictional resistance. The higher the frictional

resistance, the longer the step response time. The step response time

is also influenced by the control volume of the measuring cell. The

lower the control volume of the measuring cell, the lesser the step

response time.

The following diagram shows the typical step response times (T90) of

the different filling oils depending on the measuring cell and capil-

lary inner diameter. The values are specified in seconds per meter

capillary length and must be multiplied by the actual length of the

capillaries. The step response time of the transmitter must also be

taken into account.

1

2

3

4

5

6

7

DN50

(1 mm)

DN80

(2 mm)

500 mbar

3 bar

DN50

(1 mm)

DN80

(2 mm)

0

2

4

6

8

Fig. 8: Typical step response times (T90) in s/m for different filling oils depend-

ing on the measuring cell and capillary inner diameter. Ambient temperature =

20 °C

1 Silicone oil

2 High temperature oil

3 Med. white oil

4 Inert oil

5 Nominal width

6 Capillary inner diameter

7 Measuring cell

Step response time