2 mounting instructions – VEGA VEGAPULS 66 (≥ 2.0.0 - ≤ 3.8) standpipe ver. Profibus PA User Manual

Page 14

Make sure that all parts of the instrument in contact with the measured

product, especially the sensor element, process seal and process

fitting, are suitable for the existing process conditions such as process

pressure, process temperature as well as the chemical properties of

the medium.

You can find the specifications in chapter "Technical data" in the or on

the type label.

4.2 Mounting instructions

By using the standpipe version, the influence of turbulence and vessel

installations, such as e.g. heating spirals or agitators, is excluded. If

turbulence or vigorous product movement occurs in the vessel, long

standpipe antennas should be fastened to the vessel wall.

The standpipe antenna must extend all the way down to the requested

min. level, as measurement is only possible within the tube. If a good

mixing of the product is important, you should use a version with

perforated surge pipe.

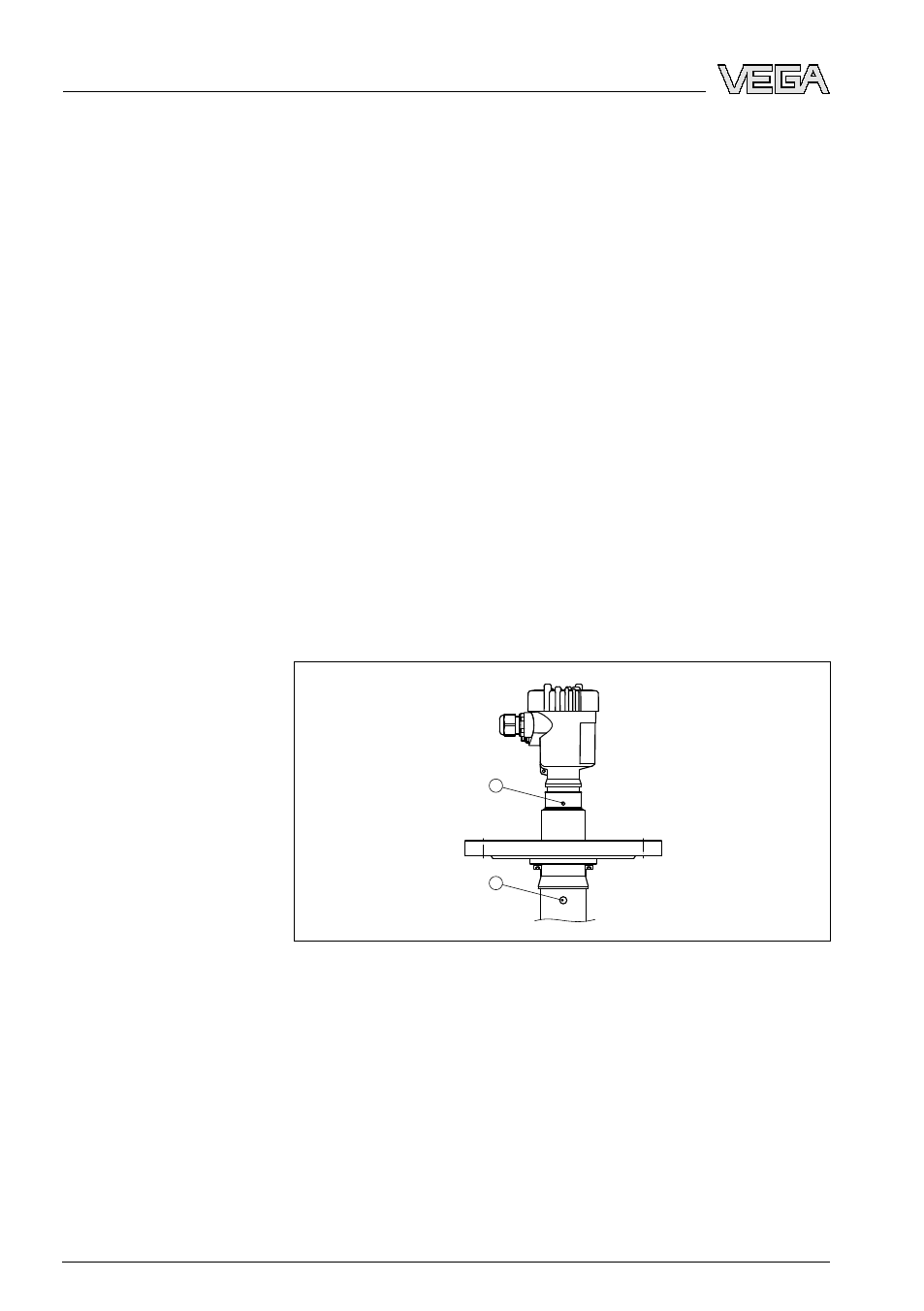

If the flange of VEGAPULS 66 was separated from the tube during

transport, make sure when mounting that the polarisation marking is in

one plane to the vent hole. Take care that the plastic tip of the radar

sensor is not damaged during transport.

1

2

Fig. 5: Polarisation marking

1

Marking of the polarisation direction

2

Vent hole ø 8 mm (0.3 in)

Suitability for process

conditions

Mounting

14

VEGAPULS

66 standpipe version • Profibus PA

4 Mounting

28743

-EN

-090305