Guidelines for standpipe construction – VEGA VEGAPULS 51K…54K Profibus PA User Manual

Page 22

22

VEGAPULS 51P … 54P

24890-EN-041227

Mounting and installation

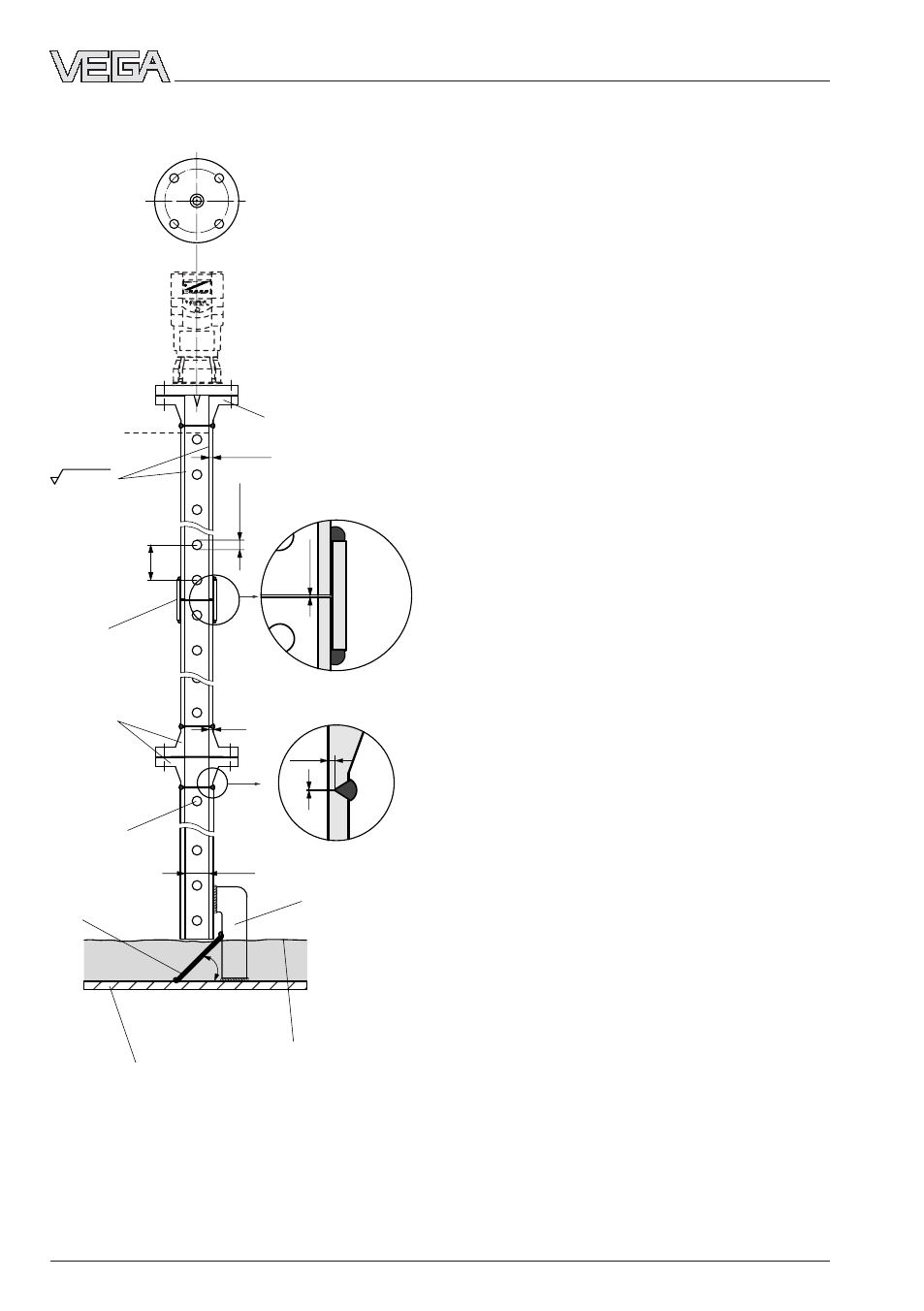

Guidelines for standpipe construction

0 %

~45˚

51,2

0,0...0,4

1,5...2

2,9

0,0...0,4

150...500

5...10

2,9...6

100 %

VEGAPULS 54

Flange DN 50

Welding neck flange

Connecting

sleeve

Welding neck

flanges

Welding of the connect-

ing sleeves

Welding of the welding

neck flange

Meas. pipe fastening

Vessel bottom

Deflector

Min. product level to be

measured (0 %)

Rz

≤ 30

Deburr the

holes

Radar sensors for measurement on surge or

bypass tubes are used with flange sizes

DN 50, DN 80, DN 100 and DN 150, whereby

the best results are achieved with 80 mm

tubes. The radar sensors with a DN 50 flange

only form a functioning measuring system in

conjunction with a measuring tube.

On the left you see the constructional fea-

tures of a measuring pipe (surge or bypass

tube) as exemplified by a radar sensor with a

DN 50 flange.

The measuring pipe must be smooth inside

(average roughness Rz

≤ 30). Use stainless

steel tubing (drawn or welded lengthwise) for

construction of the measuring pipe. Extend

the measuring pipe to the required length

with weld-on flanges or with connecting

sleeves. Make sure that no shoulders or

projections are created during welding. Be-

fore welding, join pipe and flange with their

inner surfaces flush and exactly fitting.

Avoid welding through the pipe wall. The pipe

must remain smooth inside. Roughness or

welding beads on the inner surfaces must be

carefully removed and burnished, as they

cause false echoes and encourage product

adhesion.

In the following illustration you see the con-

structional features of a measuring pipe as

exemplified by a radar sensor with a DN 100

flange.

Radar sensors with flanges DN 80,

DN 100 and DN 150 are equipped with a

horn antenna. With these sensors, a plain

welded flange can also be used on the sen-

sor end instead of a welding neck flange.