VEGA VEGAPULS 45 Profibus PA User Manual

Page 19

VEGAPULS 42, 44 and 45 – Profibus PA

19

24908-EN-041227

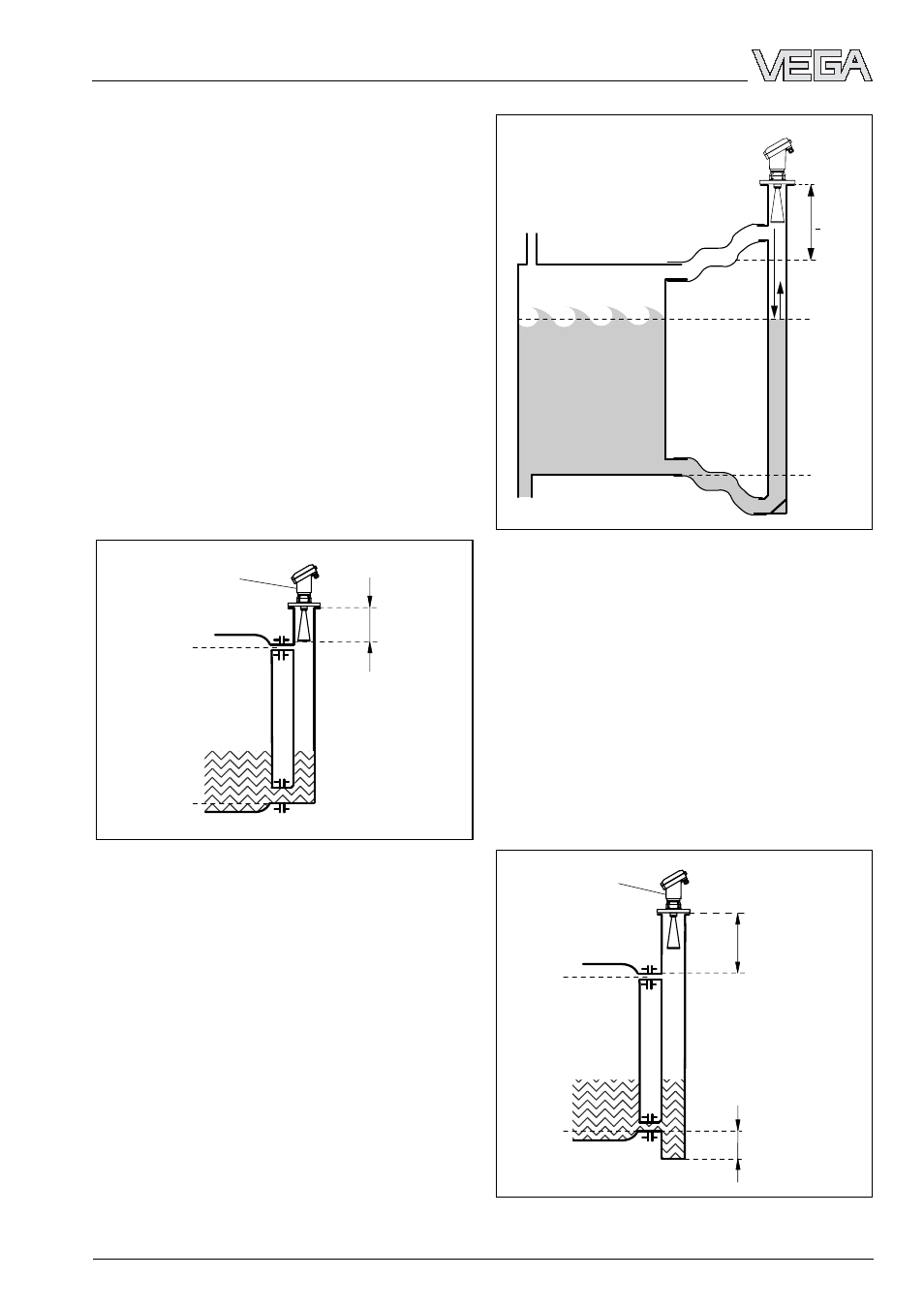

For products with small dielectric constants

(< 4), the bypass tube should have a length

greater than would normally be required for

the lower tube connection. Products with

small dielectric constants are partly pen-

etrated by the radar signals, allowing the

tube bottom to produce a stronger echo than

the product (when the bypass tube is nearly

empty). By extending the tube downward,

some liquid remains at the bottom even when

the vessel is completely empty.

Extended bypass tube on a vessel with turbulent

product movements

75 %

0 %

100 %

> 300 mm

100 %

0 %

> 300 mm

300 ... 800 mm

Tube flange system as bypass tube

Type label

Make sure the required upper vent hole in

the surge pipe is aligned with the sensor

type label.

As an alternative to a surge pipe in the ves-

sel, a pipe antenna system outside the ves-

sel in a bypass tube is also possible.

The surge and bypass tubes must generally

be made of metal. For plastic tubes, a

closed, conductive jacket is always required.

When using a metal tube with plastic inner

coating, make sure that the thickness of the

coating is minimal (approx. 2 … 4 mm).

Align the sensor so that the type label lies on

the same axis as the tube holes or the tube

connection openings. With this orientation, the

polarisation of the radar signals reduces the

intensity of false echoes caused by tube

connection openings.

When mounting a VEGAPULS 42 or 44 sen-

sor on a bypass tube (e.g. on a previous

floating or displacer unit), the radar sensor

should be placed approx. 300 mm or more

from the max. level.

100 %

0 %

> 300 mm

Tube flange system as bypass tube

Type label

Mounting and installation