Set-up – VEGA VEGADIS 371 Ex User Manual

Page 12

12

VEGADIS 371 Ex

• Set the rotating switch (7) to position 2 (relay 1 off).

With the keys (3 and 4) you can change the value of

the indication. For the given example you set the

digital indication (8) to the value 10,0 (10,0 %).

Hence the internal relay 1 switches off when this

value is decreased. The appropriate relay control

lamp (2) lights when the relay is energized. When

the switch points are too close together (< 0,1 %),

the appropriate LED flashes. The relay takes the

safe condition. In mode "Operate“ a fault signal is

displayed.

• When you want to control further relays, proceed in

the same way than for relay 1.

The positions for adjustment of the appropriate

relays are stated in the list of the rotating switch (7)

under 4.1 Indicating and adjustment elements.

Note

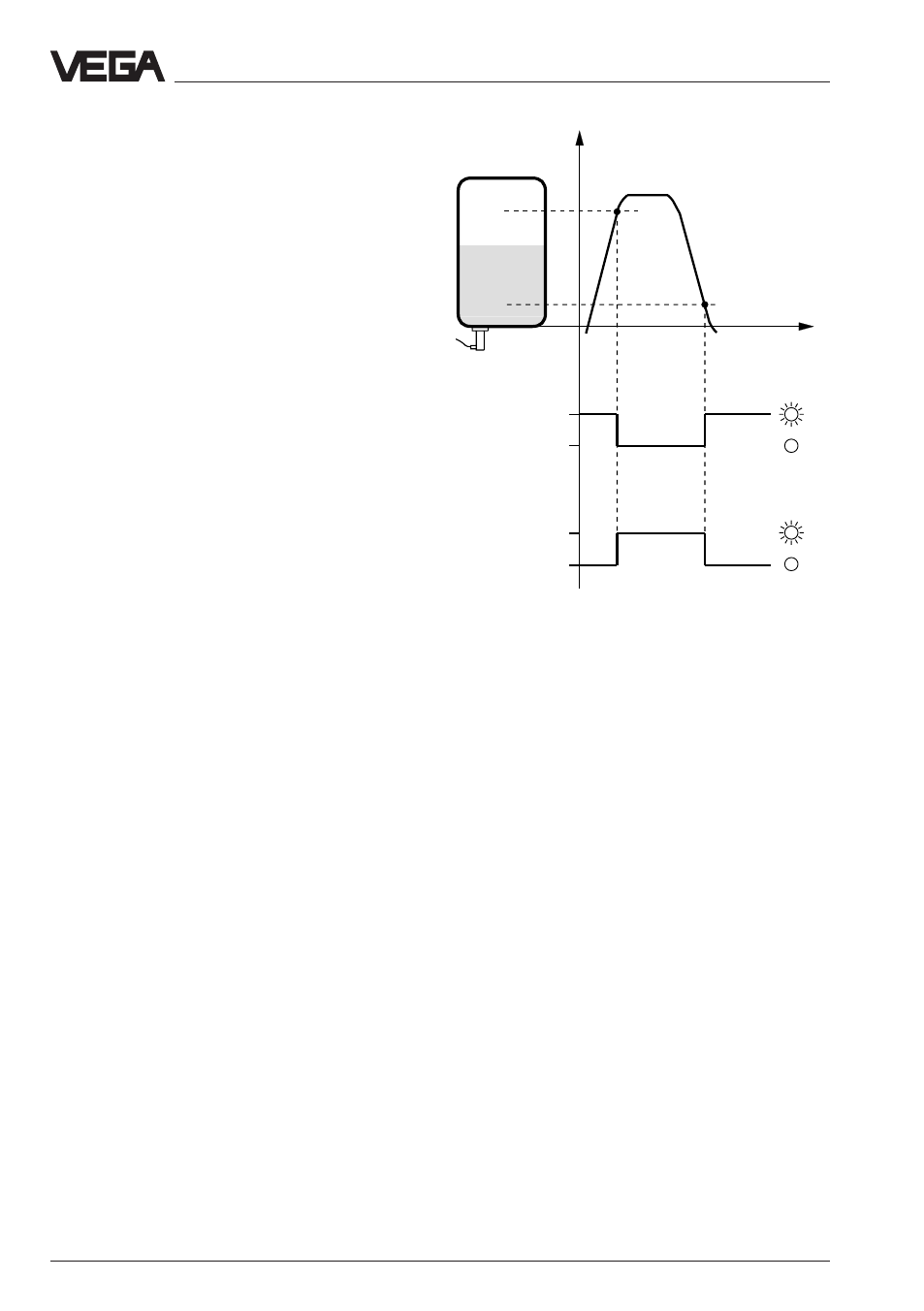

When you want to change the mode (i.e. the switching

function of the relays) you have to exchange the on

and off-values (see fig. 4.2)

• Mode A (overfill protection)

switch on point < switch off point

To adjust e.g. for relay 1 mode A (overfill protection)

you have to enter with position 1 (relay 1 on) of the

rotating switch (7) the lower value and with position

2 (relay 1 off) the higher value. Hence relay 1 is

switched off when the max. level is reached

(deenergized condition) and switched on when min.

level is reached.

• Mode B (dry run protection)

switch on point > switch off point

When you want to adjust mode B (dry run

protection) for relay 1, you have to enter with

position 1 (relay 1 on) of the rotating switch (7) the

higher value and with position 2 (relay 1 off) the

lower value. Hence relay 1 is switched on when

Set-up

max. level is reached and switch off (deenergized

condition) when min. level is reached.

Integration time

• When you want to adjust an integration time

(reaction delay), set the rotating switch (7) to

position 9.

• With the keys (3 and 4) you can change the value of

the indication (0 up to 250 seconds).

Offset correction

As a factory setting, pressure transmitters are adjusted

in a certain position. When the transmitter is

mounted in another position, the measuring range is

shifted.

• Ensure that the sensor is unpressurized.

• To carry out an offset correction, set the rotating

switch (7) to position E (Offset correction). The

display now indicates the actual sensor current in

mA or the voltage in V.

• Push the plus and minus key (3 and 4) together.

The measuring range is not modified, but

completely shifted.

• Set the rotating switch (7) to position 0 (OPERATE).

All adjusted values are transferred to an EEPROM-

memory and saved. They remain there even in case

of a probable voltage loss.

Level

off (on)

on (off)

LED

Relay on

Relay on

Relay off

Mode A

Mode B

t

Mode A (B)

Relay off

Fig. 4.2