3 electrical connection – VEGA VEGASWING 83A EXD User Manual

Page 18

18

VEGASWING 81A EXD and 83A EXD

Mounting not

suitable for

adhesive prod-

ucts

Fig. 2.7

Installation examples

Welded socket

VEGASWING has a defined begin of the

thread. This means that each VEGASWING is

in the same position after screwing in. There-

fore remove the supplied seal from the

thread of VEGASWING. This seal is not re-

quired when using a welded socket. Screw

VEGASWING into the welded socket.

You can deter mine the later position of

VEGASWING already before welding (see

fig. 2.2). Mark the appropriate position of the

welded socket. Before welding you have to

unscrew VEGASWING and remove the rub-

ber ring out of the welded socket.

Optionally a welded socket is available which

is already provided with a marking. Weld this

welded socket with the marking to the top

(see fig. 2.6).

Fig. 2.6

Marking

Mounting, electrical connection

3 Electrical connection

Danger

Switch off the power supply before starting

connection work.

The electrical connection must be carried out

dependent on the integral oscillator . Connect

mains voltage according to the following

connection diagrams. Note the following

special instructions for electrical connection in

Ex-areas.

When connecting the voltage supply or re-

connecting the sensor , the instrument passes

the function test (only with oscillator

SWING E82Z and connected signal condi-

tioning instrument). See also "5.1 Recurring

test acc. to WHG “.

Note

If strong electromagnetic interferences have

to be expected, we recommend to use

screened cable for the Z-electronics. The

screening of the cable must be earthed on

the sensor side (VEGASWING) via the inter -

nal earth terminal.

Generally connect VEGASWING with P A. Use

the earth connection terminal on the housing.

• Interrupt all lines to the sensor (voltage

supply and signal lines) on the switching

cabinet.

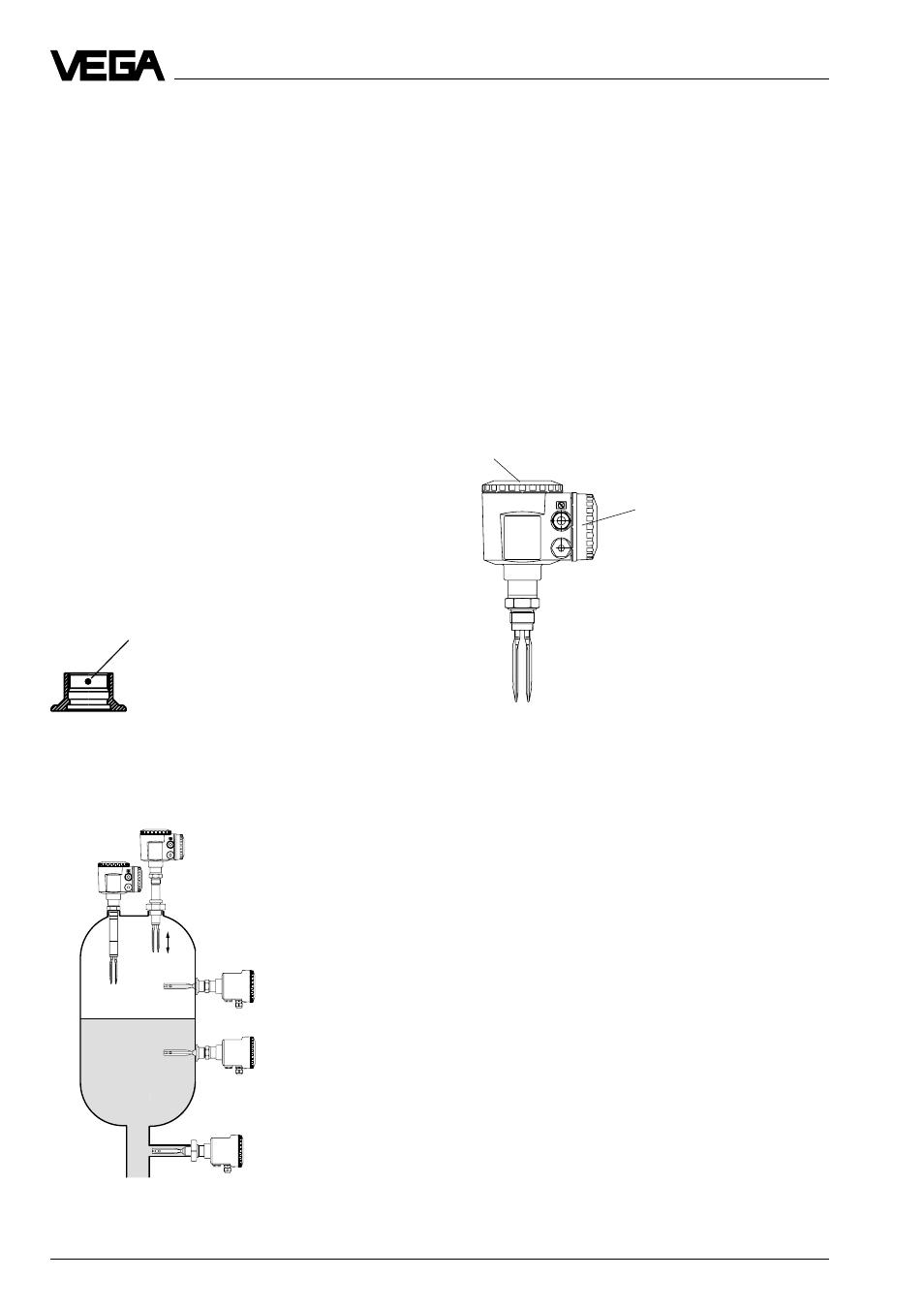

Fig. 2.8

Connection box

(small cover)

Electronics box (large cover)