2 mounting, 1 vegaswing, Transport – VEGA VEGASWING 83A EXD User Manual

Page 15: Switch point, Vertical installation, Horizontal installation, Adhesive products

VEGASWING 81A EXD and 83A EXD

15

Mounting

2 Mounting

2.1 VEGASWING

Generally VEGASWING can be mounted in

any individual position. The instrument must

be mounted such that the tuning fork is at the

height of the requested switch point. Note the

following installation instructions:

Transport

Do not hold VEGASWING on the tuning fork.

Especially with flange or tube versions, the

tuning fork can be damaged by the instru-

ment weight. Transport enamelled and

ECTFE-coated instruments very carefully and

avoid touching the tuning fork.

Switch point

The tuning fork is provided with lateral mark-

ings (notches) marking the switch point with

vertical installation relating to the medium

water. Note when installing VEGASWING that

the marking is at the height of the requested

level. Note that the switch point of the instru-

ment shifts when the medium has a density

deviating from water (water = 1,0 g/cm

3

). The

switch point can be adapted via a potentiom-

eter, to set the switch point to the marking

(notch). With the adjustment 1,0 g/cm

3

a

switch point from a density of ³ 0,7 g/cm

3

is

ensured. For products with a density < 0,7 g/

cm

3

the potentiometer must be readjusted on

the oscillator. Oscillator SWING E82 Z:

0,5 … 1,0 g/cm

3

(see fig. 2.1). The switch

point adaption is described under "4 Set-up “.

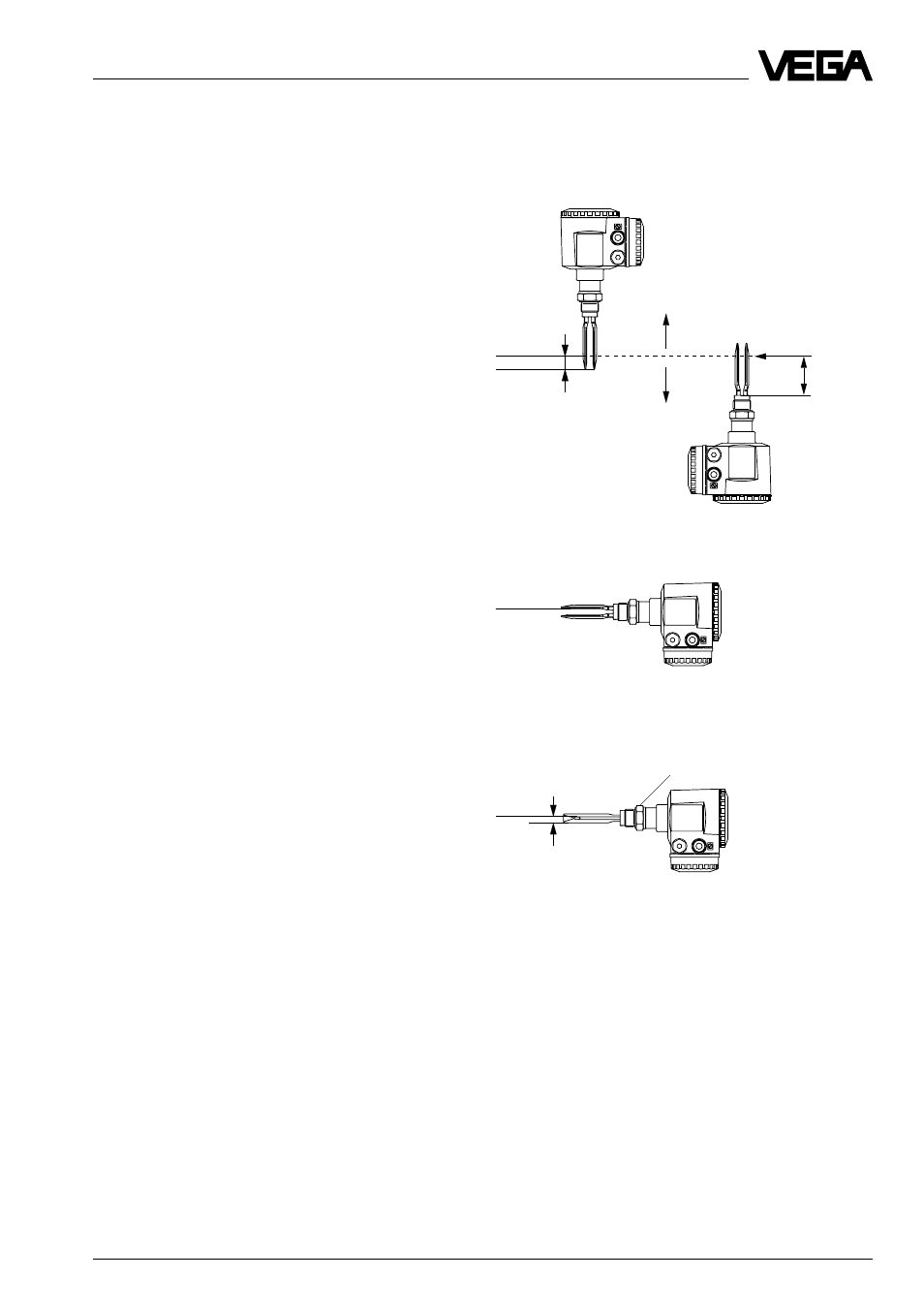

Vertical installation

from top, from bottom

Switch

point

Switch

point

Switch point at

higher density

Switch point with

low density

75 mm

approx.

25 mm

Horizontal installation

Switch point

Switch

point

Top marking

Fig. 2.1

Fig. 2.2

Recommended installation position for adhe-

sive products:

Adhesive products

In case of horizontal mounting in adhesive

and viscous products, the surfaces of the

tuning fork should be vertical to reduce build-

up on the tuning fork (see fig. 2.2). The posi-

tion of the tuning fork is marked by a notch

on the hexagon of VEGASWING. Therefore

you can check the position of the tuning fork

when screwing in. When the hexagon is on

the seal, the thread can be still turned by

approx. half a turn. This is sufficient to reach

the recommended installation position.

approx.

15 mm