2 mounting, 1 general information, 2 vegakon 61 – VEGA VEGAKON 63 User Manual

Page 7: 3 vegakon 63

VEGAKON

7

Mounting

2 Mounting

2.1 General information

-

Remove the seal ring before welding the socket.

-

In case of pressure in the vessel, VEGAKON must

be sealed at the thread. Cover the thread with

Teflon, hemp etc. or use the attached seal ring.

-

A fitting, VEGAKON 63 must only be used in

unpressurized vessels.

-

In case of extreme vibration and shock, e.g. by

stirrers or turbulence in the vessel etc., the

extension tube of VEGAKON 63 may vibrate. A

fixing should be used to eliminate vibration.

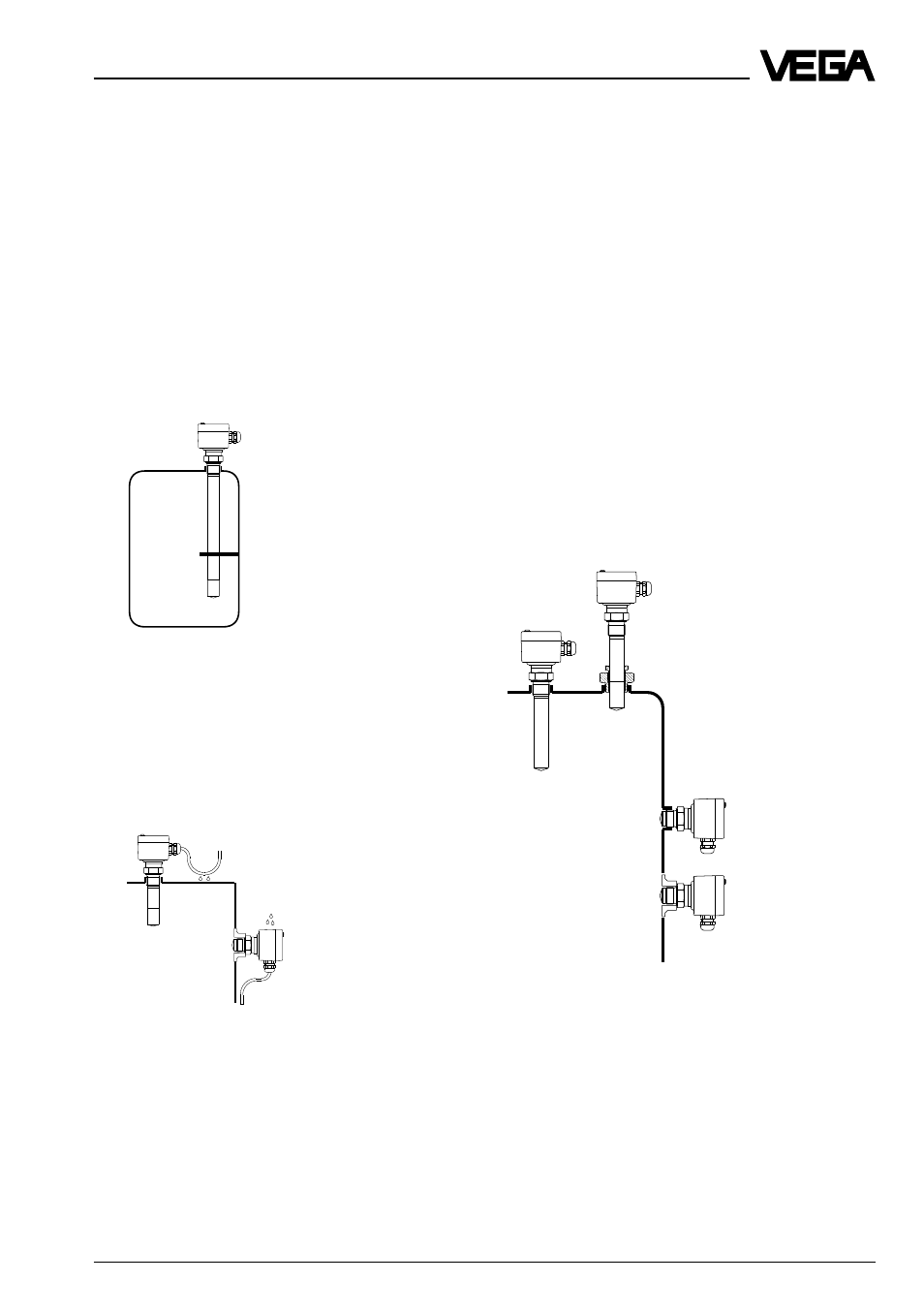

2.2 VEGAKON 61

Observe that the standard or hygienic mounting

bosses used for mounting are flush with the inner wall

of the vessel.

This ensures the correct position of the annular

electrode.

2.3 VEGAKON 63

The switch point can be fixed on a socket with thread

G1 A or via a previously welded standard socket

(thread G 1 A).

With a fitting (mounting thread G 1

1

/

2

A) the switch

point remains variable by adjustment of height.

Please note that when the switch point is high the

position of the annular electrode must be still within the

inner part of the vessel.

fixed switch

point

variable

switch point

Fitting

fixed switch point

e.g. min. signal

fixed switch point

e.g. max. signal

Standard

mounting boss

Hygienic socket

Note:

In case of very adhesive products the VEGAKON

should not be flush with the side walls or the vessel

bottom if they are still covered with a thick layer even

when the vessel is empty.In this case it is better to use

a short VEGAKON 63 (e.g. 100 mm length) so that the

electrode extends through the remaining product

layer.

VEGAKON 63

Welding nozzle

Fixing facility

-

After electrical installation (horizontally) turn the

housing such that the cable entries point

downwards. This avoids humidity ingress. The

housing can rotate through 330

°

. In case of vertical

mounting lead the connection line (s) from the

cable gland first downwards so that rain and

condensation water can drain off.