Ordering information – Veris Verabar V550 Spec Sheet User Manual

Page 3

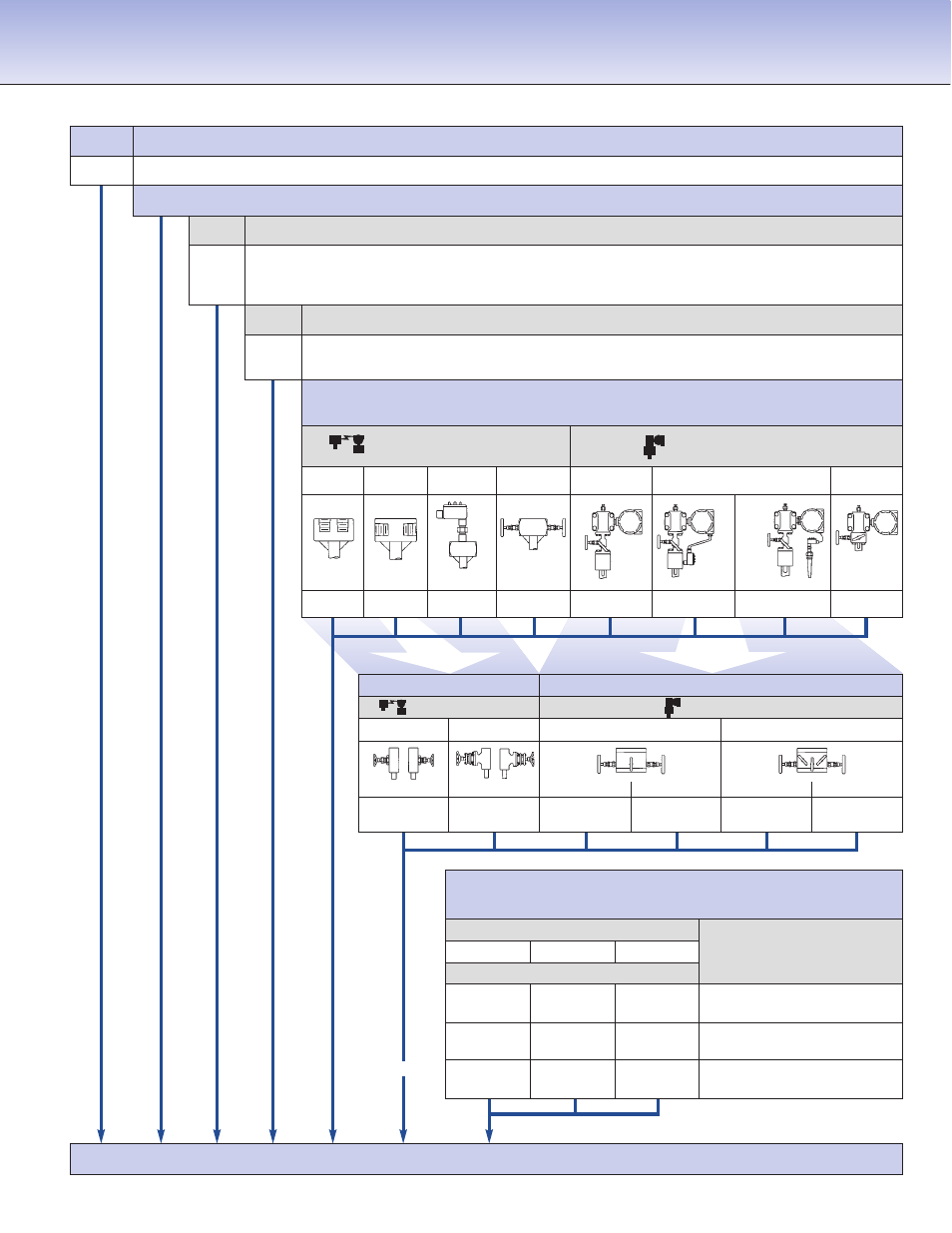

Model

Flanged

V550

Spring Lock

Pipe Size and Schedule or Exact ID and Wall Thickness

Code Sensor Pipe Size Range

05

2” to 6” (50mm to 150mm)

10

6” to 42” (150mm to 1050mm)

15

12” to 60” (300mm to 1500mm)

Code Pipe Orientation

H

Horizontal

V

Vertical

Instrument Connections

(Select Remote or Direct Mount)

(Transmitter sold separately)

Remote Mount Transmitter

Direct Mount Transmitter

(1/2” NPT)

(Flanged 450°F/232°C Max.)†

Parallel

Regular

RTD

*

Valve

Transmount

Mass Transmount

*

Manifold

P

R

D

T

F

G

E

M

V550

8”sch 40

10

H

R

C2NC

F615C

Typical Model Number

Ordering Information

Mounting Assembly — Select Material & Rating

(Includes SS sensor flange, WN flange, weld coupling,

spiral-wound gasket, studs & nuts)

Sensor

(Flange Size)

05 (1”)

10 (1-1/2”)

15 (2”)

Mating Flange Material

Code

& ANSI Class

F415C

F615C

F815C

CS

150#

F415S

F615S

F815S

SS

150#

F430C

F630C

F830C

CS

300#

F430S

F630S

F830S

SS

300#

F460C

F660C

F860C

CS

600#

F460S

F660S

F860S

SS

600#

Optional

Instrument Valves

(Opt.)

Manifolds

(Optional)

Remote Mount

Direct Mount

Needle

Gate

3-Valve

5-Valve

C2NC (CS)

C2GC (CS)

F3SC (CS)

F3HC (CS)

F5SC (CS)

F5HC(CS)

C2NS (SS)

C2GS (SS)

F3SS (SS)

F3HS (SS)

F5SS (SS)

F5HS (SS)

1/2” NPT

Soft Seat

Hard Seat

Soft Seat

Hard Seat

1/2” NPT

Explsn. Proof

Remote

RTD

Integral

RTD

Integral

Integral

*

For high pressure (>500psig) or high temperature (>500°F), remote mount RTD in a thermowell is preferred.

† Assuming adequate heat dissipation for transmitter.