Verabar, Hot tap models, Flow calculation – Veris Verabar V450 Spec Sheet User Manual

Page 2: Select model from page 3, Pipe or duct orientation, Enter flow conditions, V450 low pressure, Model v450

Vera

bar

®

Vera

bar

Flow Calculation

Program

Flow Calculation

Program

5.

Flow Calculation

All Verabar applications require a flow calculation to verify

the DP, pressure and temperature limits, structural limits

and to size the transmitter. The Veracalc PC Program

is for use by representatives and end users. It is easy

to operate and includes steam tables.

Verabar

®

Hot Tap Models

4.

Select Model from Page 3

Use the Ordering Information table on Page 3 to determine your

model number.

Short

Straight Run

Consult Factory

(V) Vertical

(H) Horizontal

Pipe Size _____ Sch _____

Pipe ID _____ and

Wall _____ Pipe Mat’l _____

Wall

Height (H) _____

Width (W) _____

Wall _____

Duct Mat’l _____

Dimension

Verabar spans

(H) or (W)

Fluid Name:

Maximum

Normal

Minimum

Units

Flow Rate

All

Temperature @ Flow

Fluids

Pressure @ Flow

Gas

Specific Gravity, or

Molecular Weight

Liquid

Specific Gravity

Steam

Veracalc Program can calculate Density from Temperature and Pressure

ID

W

H

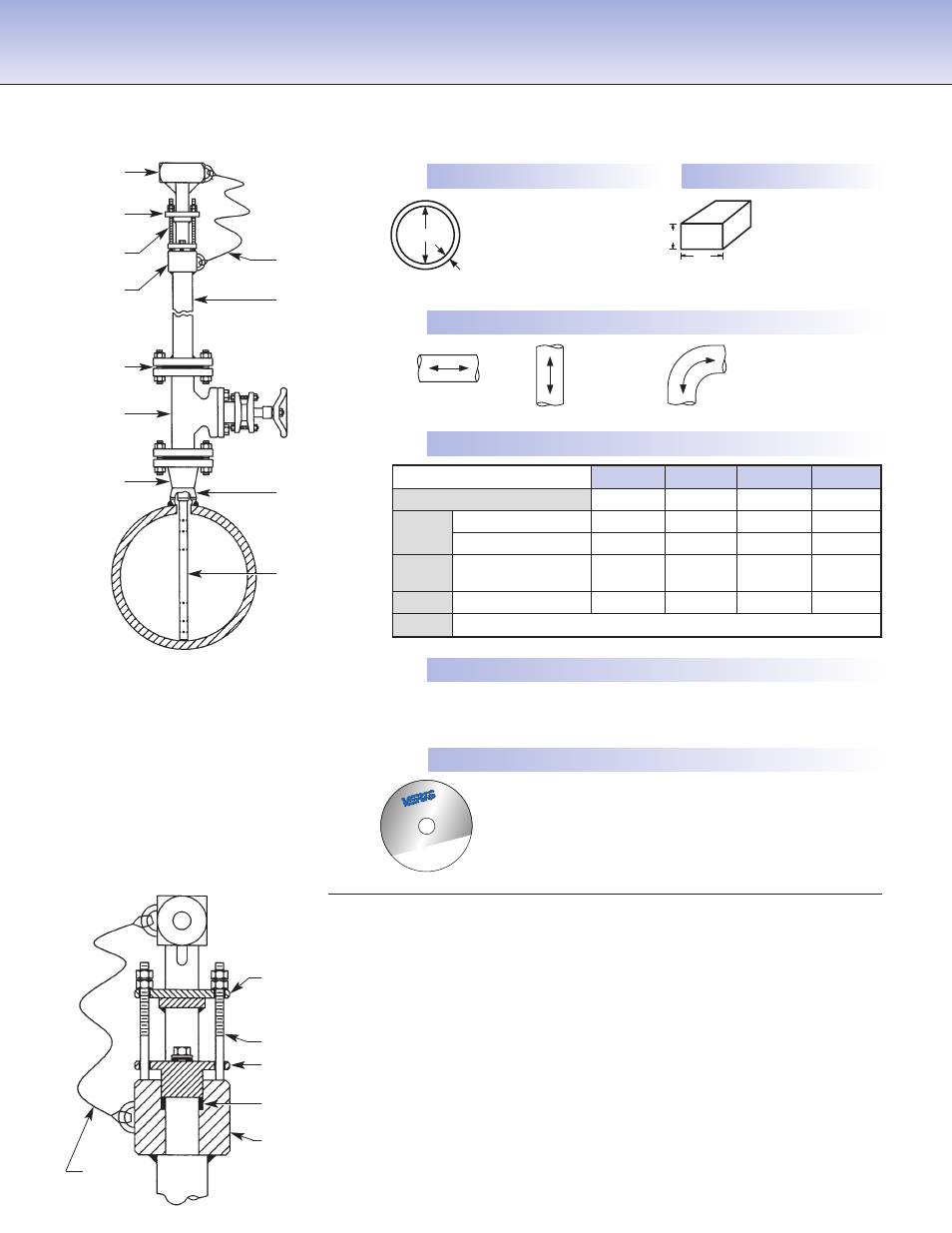

2.

Pipe or Duct Orientation

3.

Enter Flow Conditions

1.

Enter Pipe Dimensions or Duct Dimensions

Furnish the following information:

Retaining Hardware

• Eliminates drive rods

• Safety cable limits retraction length to ensure proper sealing

of packing gland

• Retaining ring loads sensor to opposite pipe wall

V450 Low Pressure

Instrument

head (SS)

Access valve

flange (CS)

(SS opt)

Retaining

ring (SS)

Packing

gland (SS)

Studs & nuts

(SS)

Retaining ring

(SS)

Access

nipple (SS)

Follower (SS)

Weld coupling

(CS) (SS-opt)

Spiral-wound

gasket (2)

Sensor (316SS)

Safety

cable (SS)

Safety

cable (SS)

Safety studs (SS)

Packing gland

(SS)

Model V450

Graphite packing

Weld neck

flange (CS)

(SS opt)