Veris Verabar V500_V510 Installation Instructions User Manual

Page 3

5.2

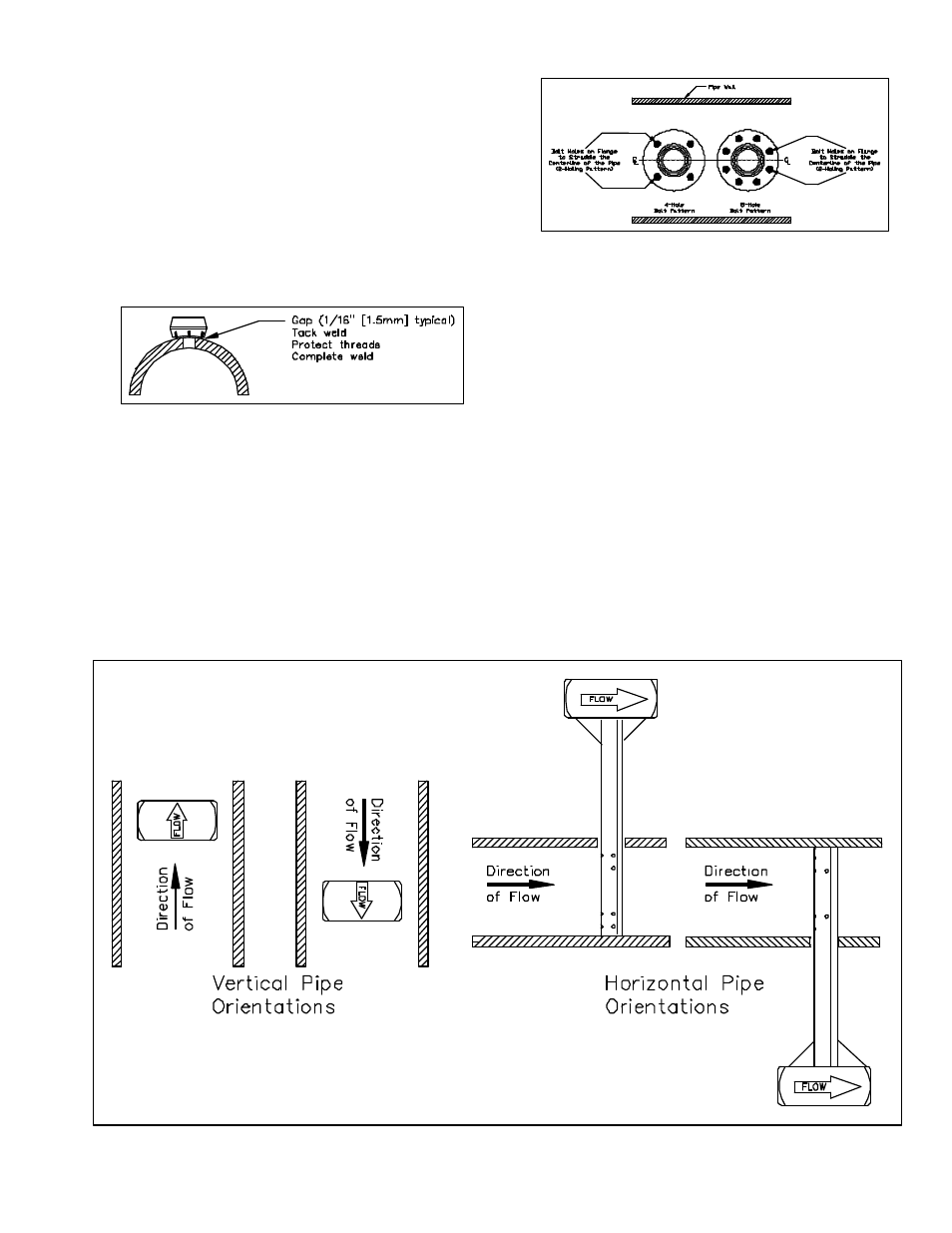

Weld Mounting Flange to Pipe

•

Loosely bolt together (hand tight) the sensor,

gasket and mounting flange. Insert the assembly

into the pipe. Align the head of the sensor so that

the arrow labeled “flow” on the head is in the

direction of the flow to within 3°. The contour of

the weld coupling should match the contour of the

pipe. Check that the bottom of the weld coupling

is in contact with the pipe wall.

•

Using the appropriate weld gap (1/16” [1.5mm]

typical), tack weld the mounting flange into

position (Figure 3).

Figure 3. Weld Gap

•

Note the flange orientation per Figure 4. The bolt

holes on the flange should straddle the centerline

of the pipe (2-holing pattern). For V510 models,

slide the opposite end weld coupling over the tip of

the sensor and tack weld into position.

•

Remove the sensor and finish welding the weld

coupling(s) per applicable piping codes. For V510

models, weld the weld coupling and weld cap into

position.

Figure 4. Flange Orientation

5.3

Insert Sensor

Install the sensor with the gasket between the flanges

such that the flow arrow on the head of the sensor is in

the direction of the flow (Figure 5). The nuts should be

tightened until the gasket is completely crushed (the

gasket thickness should be approximately 1/8” [3mm]).

5.4

Insert Instrument Valves or Manifold

5.4.1 Valves

If the Verabar does not have a valve head, install

instrument valves using proper thread sealant. Be sure

instrument shut-off valves are installed and shut prior to

repressurizing the pipe.

5.4.2 Manifold

If the Verabar has a direct or integral manifold, be sure

the high and low pressure block valves are shut off prior

to repressurizing the pipe.

Figure 5. Orientation of Flow Arrow