Veris Verabar V200D Installation Instructions User Manual

Page 4

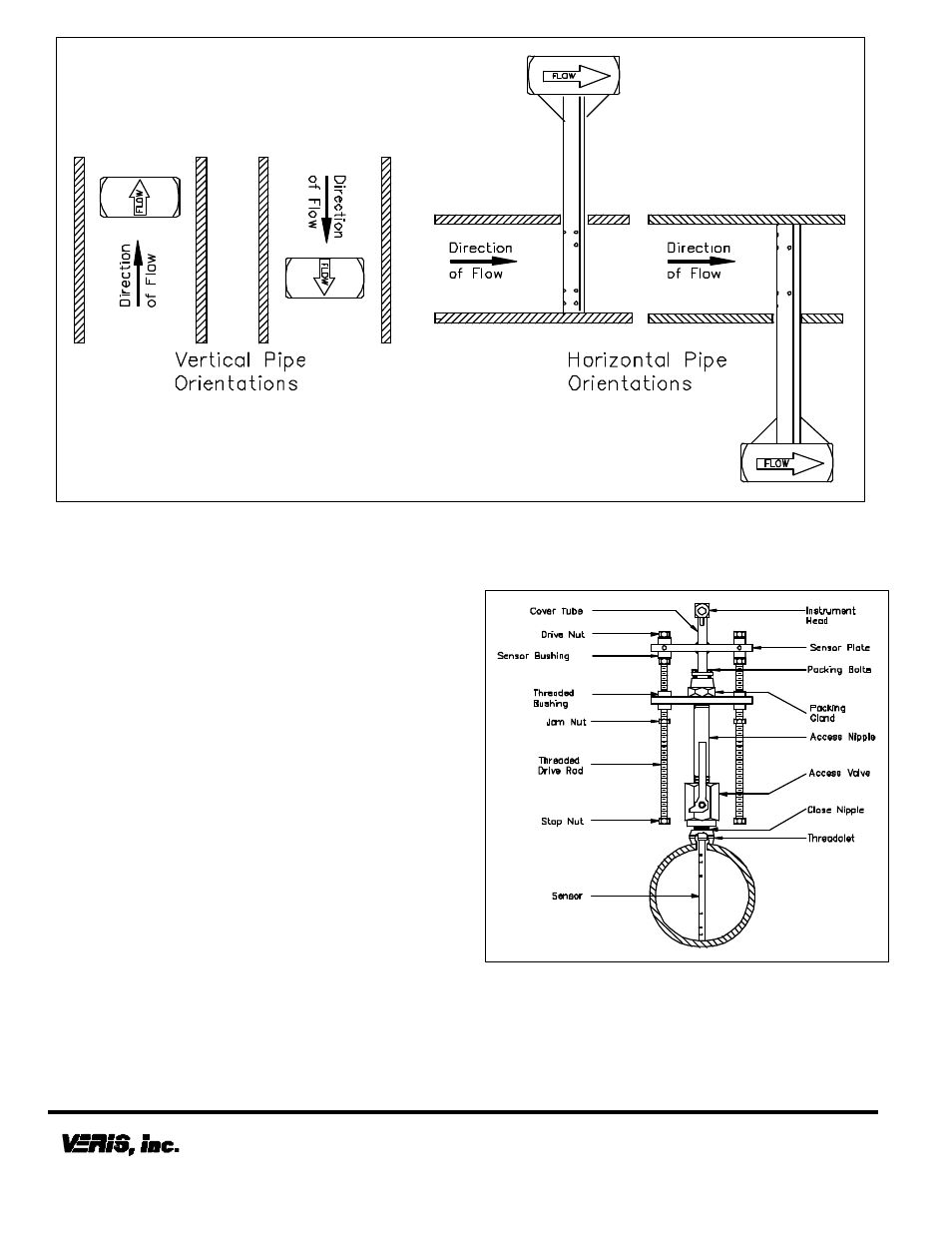

Figure 6. Orientation of Flow Arrow

•

The tip of the sensor should completely bottom on

the opposite end of the pipe. Continue to insert

the sensor until firm resistance is met. This will

occur when the sensor plate is approximately 2”

(51mm) from the top of the packing gland.

•

Thread the jam nuts toward the threaded bushings.

The jam nuts should press tightly against the

threaded bushings. This will lock the drive rods in

place and maintain the sensor position in the pipe.

Periodic Maintenance

The assembly should be periodically checked. Verify

that no leaks are present. The jam nut and packing bolts

should be tight.

Sensor Removal Procedure

•

Shut off instrument valves.

•

Reduce flow rate to below the maximum insertion

withdrawn DP/flow limit stated on the Verabar tag.

•

Loosen jam nut. Using the drive nut, retract the

sensor until the stop nut and jam nut are pressing

against the threaded bushing.

•

Completely shut off the access valve. Slowly

crack open one of the Verabar instrument valves

and bleed off any remaining pressure contained in

the access nipple. The sensor assembly can now

be removed.

The Verabar is now properly installed (Figure 7).

Figure 7. Installed V200 (Double)

6315 Monarch Park Place

•

Niwot, CO 80503 USA

•

Phone: (303) 652-8550

IO

-200D VWI-CS-024 REV B (6/08)

Fax: (303) 652-8552

•

Email: [email protected]

•

Website: www.veris-inc.com

Printed in USA