Veris Verabar V100 User Manual

Page 2

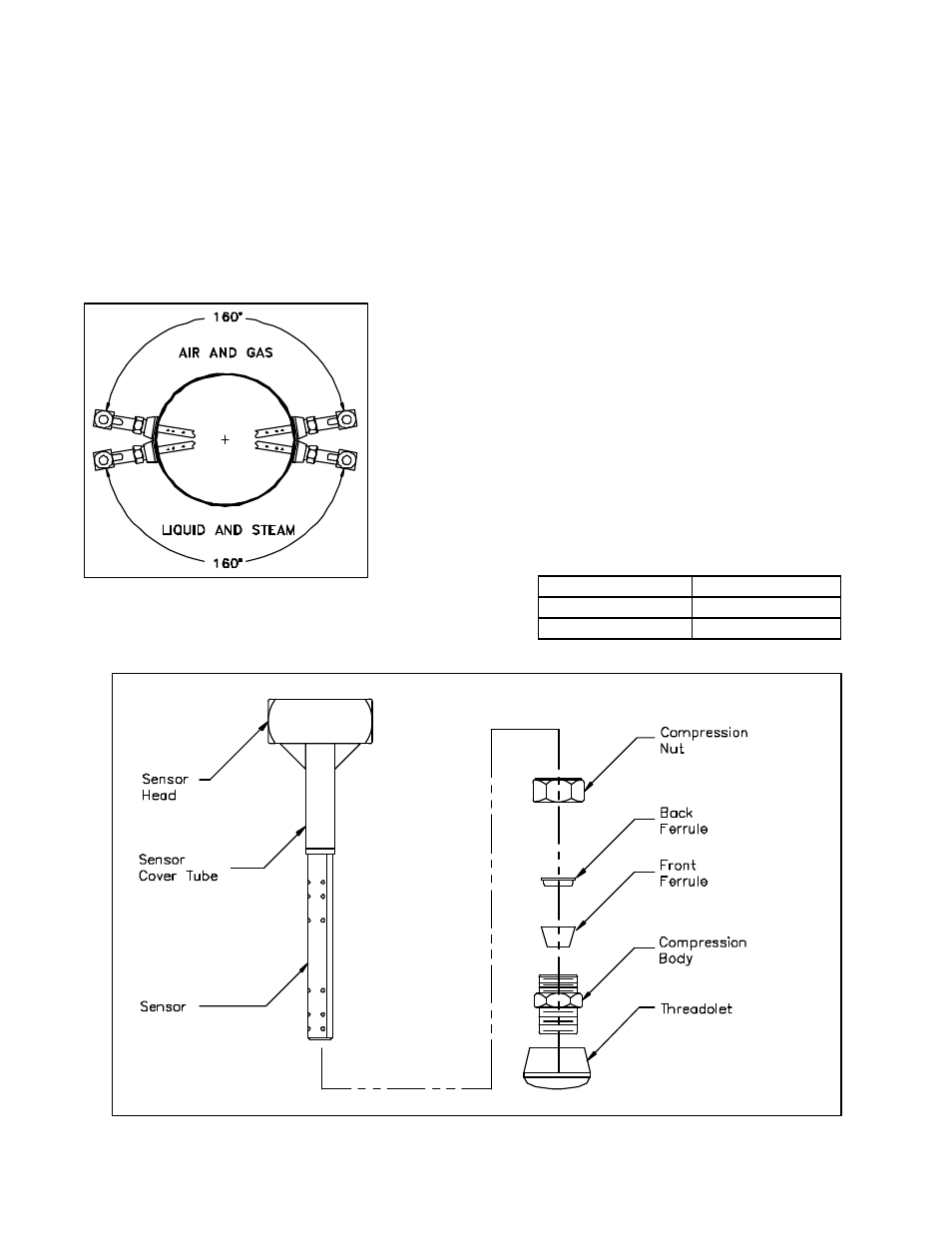

4.2.1 Horizontal Piping

For air or gas installations, mount the Verabar in the

upper 160° of the pipe to allow any condensate to drain

into the pipe (Figure 1). For liquid or steam installations,

mount the Verabar in the lower 160° of the pipe. This

allows any entrained air to bleed back into the pipe for

liquid applications and allows condensate to collect in

the instrument piping for steam applications.

4.2.2 Vertical Piping

The Verabar may be mounted in any location around the

circumference of the pipe for any vertical piping

applications (Figure 1).

Figure 1. Verabar Orientation in Horizontal Pipe

4.3

DP Transmitter/Local Indicator

Location

When choosing a Verabar location, consider the DP

transmitter/local indicator location:

•

The transmitter must be mounted below the

Verabar for liquid and steam applications.

•

The transmitter must be mounted above the

Verabar for air and gas applications.

4.4

Installation Drawings and Bill of

Materials

Additional information is available in the Installation

Drawings and Bill of Materials VB-7061 (also on the

VeraData CD). It contains standard and alternate

transmitter locations and a complete bill of materials

based on the fluid type and sensor orientation on the

pipe.

5.0

INSTALLATION PROCEDURE

5.1

Drill Hole in Pipe

•

Completely depressurize and drain pipe prior to

installation of the Verabar.

•

Mark the location of the hole through which the

Verabar will be mounted. Use a center punch to

mark the hole to prevent the drill bit from walking

on the pipe.

•

Drill the pipe with the proper sized hole per the

following table:

Sensor Size

Hole Dia

V100-05

1/2" (13mm)

V100-10

1” (25mm)

•

Deburr the hole on the inside of the pipe.

Figure 2. Verabar Model V100