Aluminum parabolic louvers, Vd lighting b a sic s, Opvdt series – Oracle Lighting OPVDT-22 User Manual

Page 2: Vd t b as ics, Rp1 ies

50

www.oraclelighting.com • tel: 1-877-375-5555 • FaX: 1-877-375-3333

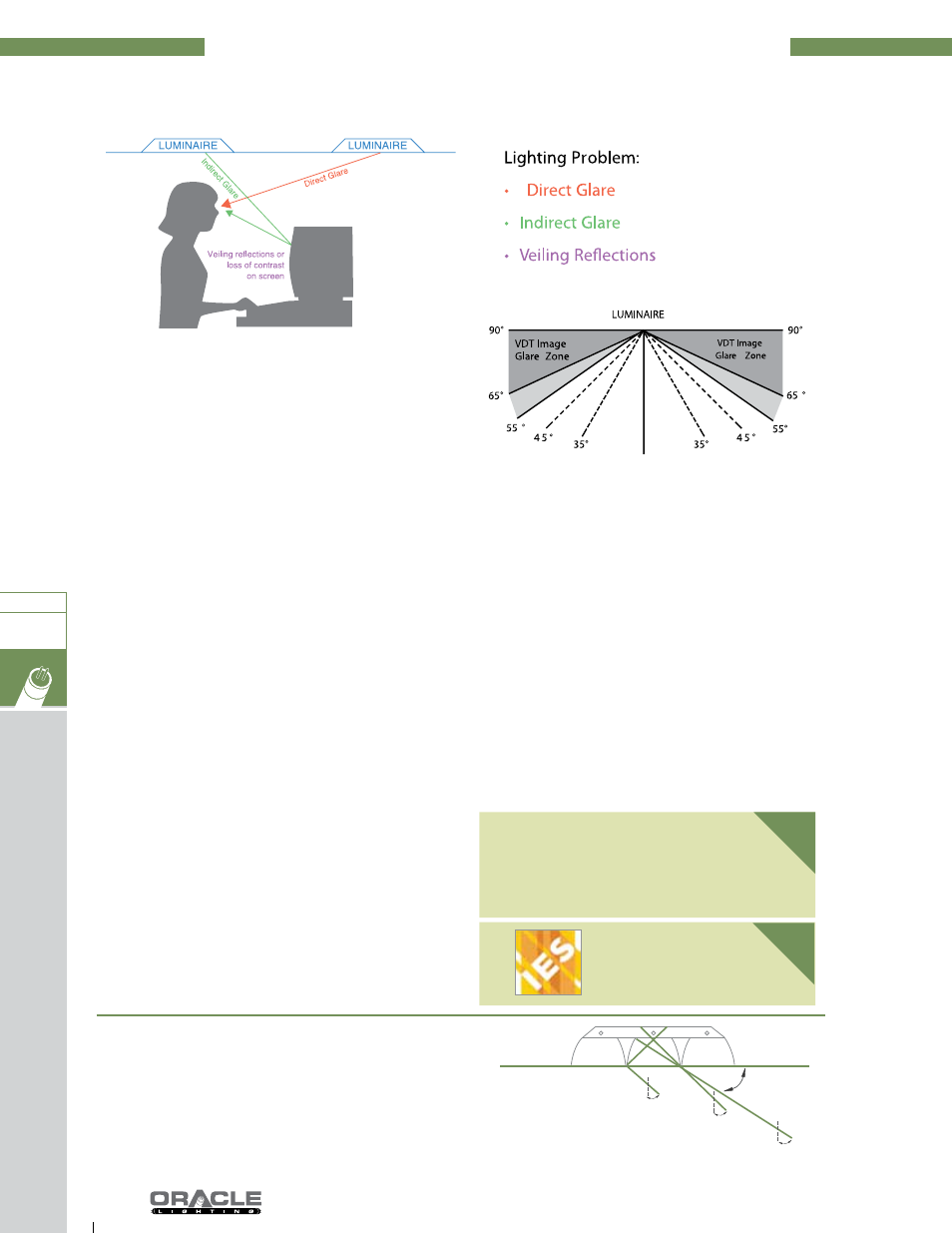

Lighting Solution:

• Select luminaires that minimize intensity in the 55° or 65° to 90°

zone.

• In “vdt normal” spaces with a mix of paper and non-critical

vdt tasks, the ies recommends that the luminous intensity in

the lengthwise, crosswise and 45° vertical planes should not

exceed*:

300 candelas at 65° from vertical

185 candelas at 75° from vertical

60 candelas at 85° or more from vertical

• In “vdt intensive” spaces where the majority of the time is spent

viewing the vdt, the ies recommends that the luminous intensity

in the lengthwise, crosswise, and 45° vertical planes should not

exceed*:

300 candelas at 55° from vertical

220 candelas at 65° from vertical

135 candelas at 75° from vertical

45 candelas at 85° from vertical

• Select luminaires with shielding angles of at least 30° in all direc-

tions.

• Design to a maximum of 50** maintained footcandles on the

horizontal work plane.

• Locate vdt terminals between rows of luminaires when possible.

Other Considerations:

• Windows should be treated with blinds or curtains to eliminateex-

cessive brightness.

• Most vdt terminals may be tilted (up or down) or turned (side to

side) to minimize reflected glare.

• White clothing worn by operator may cause some loss of contrast

on screen.

• Negative contrast monitors (dark detail on a light background)

frequently make reflected glare less noticeable.

• Monitor design (screen curvature or flat screen, screen reflec-

tance properties, etc.) can make significant differences in visual

performance.

• Use of screen filters supplied by manufacturers of visual display

terminals helps to reduce screen glare.

• Partitions may be located as needed to reduce reflections from

windows or luminaires. Source: iesna rp-1 (2004) recommended

practice for lighting offices containing computer visual display

terminals.

*These values are candlepower rather then luminance values as in

previous recommendations.

**Illuminating engineering society of north America (iesna) recom-

mended level.

Louver Iridescence:

• Iridescence Phenomena, present on lighting sheet reflectors, is

caused by the refraction of light by the thin anodic coating that

produces either cancellation or reinforcement of certain wave-

lengths of light. This “rainbow effect” appears primarily as various

shades of green and pink that can change color at different view-

ing angles.

• Iridescence has always been present on lighting sheet reflectors,

but to a very subtle, often un-noticeable degree with the tradi-

tional fluorescent light sources that emitted a broad spectrum of

light. With the introduction of fluorescent light sources that utilize

rare-earth phosphors and emit distinct wavelengths of light, the

phenomena of iridescence has been intensified and has become

an aesthetic problem to the user. It should be recognized that the

presence of iridescence does not detract from the optical perfor-

mance of the lighting sheet reflector.

• Unfortunately, there is currently no quantitative way to measure

iridescence, so we are left with a purely subjective evaluation

of what is objectionable and this can vary from individual to

individual.

• Low iridescence aluminum is recommended for use with T8,

compact fluorescent TT5, and other tri-phosphor lamps.

alUminUm ParaBolic loUVerS

-oPVDt SerieS-

VD

lighting

B

a

Sic

S

illUminating

engineering

SocietY oF north america

ieS recommenDeD

Practice For

lighting oFFiceS

containing

comPUter ViSUal

DiSPlaY terminalS

RP1

The blades of a parabolic louver provide a physical cut-off

in the same way as in an “egg-crate” louver, however, a

parabolic louver with a specular silver finish reflects all

light from its curved blades at an angle equal to or less

than the louver cut-off angle

V

D

t

B

as

ics

OPTICAL CUT-OFF ANGLE

LAMP CUT-OFF ANGLE

LOUVER CUT-OFF ANGLE

SHIELDED ZONE

CEILING MOUNT

RP1

IES

T8/T5

OPVDT