Brakelock installation – Blue Ox BX8881 User Manual

Page 2

292-2083 4/97 2 of 3

5.

After you have confirmed that the location for the hole

will not cause any problems, pull the carpet back and

drill a 1/8 inch pilot hole. Allow the drill bit to just barely

break through the metal floor. Next, inspect where the

hole actually is from the engine compartment side to

verify that this location will not cause problems and to

see how the cable aligns with the brake arm. If the hole

needs to be relocated slightly, re-drill and seal the

previous hole with a rivet or sealant. When alignment is

correct, enlarge the pilot hole with a 1/4 inch bit.

6.

Cut a slit in the carpet to correspond with the hole in the

floor. Slide the large flat washer over the cable housing

then feed the housing through the carpet and hole in the

floor following your selected route as mentioned before.

Do not make a turn tighter than a four (4) inch radius. If

you need to make a bend in the housing you will need to

anchor the housing in the middle of the bend with plastic

cable ties available at most automotive and hardware

stores. When installed properly, the flared end of the

housing and the washer should be showing on top of the

carpet. Avoid abrupt bends in the cable housing. Hold

the end of the housing up to the rear of the Brakelock to

determine the length needed and cut off excess housing

with a pair of side cutters.

BRAKELOCK INSTALLATION

7.

Lubricate the brake cable with silicon spray and feed the

cable from the Brakelock back through the cable

housing. Secure the cable housing to the rear of the

Brakelock body using the #567 flag terminal #10 washer

and #10 screw provided in the parts bag.

8.

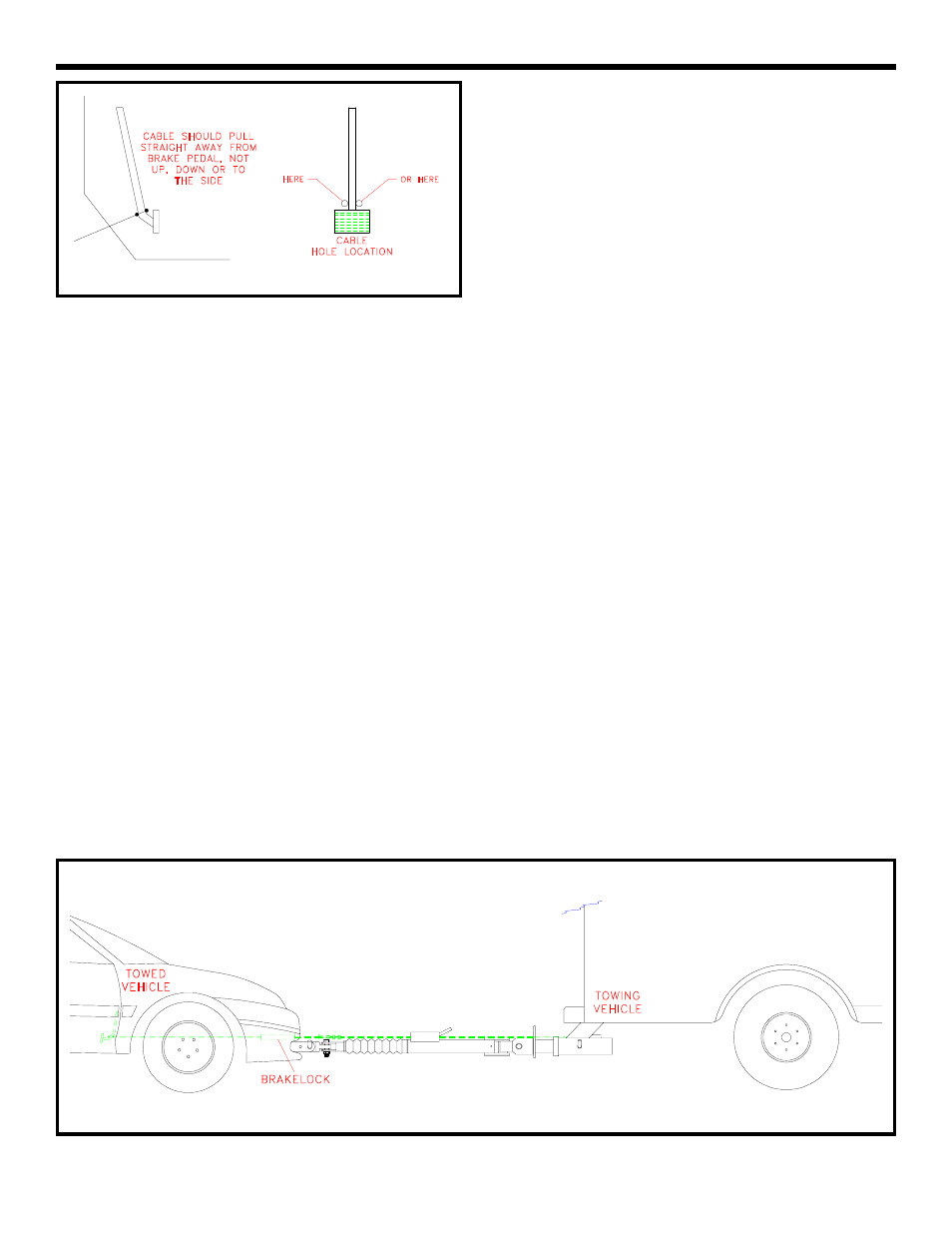

Loop the end of the cable around the brake pedal arm

allowing the cable to feed directly and straight into the

cable housing. Remove all of the slack in the cable,

double the cable back on itself and secure it with the two

U-bolt style cable clamps provided in the parts bag. Cut

off the excess brake cable with a pair of side cutters.

(Figure 2) IMPORTANT: Be sure to locate the cable

clamps so that they will not come in contact with the

floor when the brake pedal is depressed.

9.

Using the ring detent pin, attach the cable fork of the

connector cable to the fuse on the brake cable at the

front side of the Brakelock. Extend the connector cable

to determine the length needed for the S-hook to reach

the towing vehicle. NOTE: Most hitches have holes or

loops provided to attach safety cables while towing.

This is a good location to attach the S-hook of the

connector cable. If your hitch does not have these,

locate another suitable location in line with the Brakelock

to attach the S-hook.

10. With the S-hook attached there should be about 3-4

inches of vertical play in the connector cable. If this is

not the case, you must loosen the cable clamps and

adjust the length of the connector cable. When adjusted

properly, cut the excess cable off and discard. NOTE:

Be sure to tighten the cable clamps completely.

11. Install all other safety and towing equipment as required.

IMPORTANT: The Brakelock does not eliminate the

necessity of safety chains, towing lights, transmission

pumps or driveshaft disconnects. It is designed solely to

apply the brakes in the event the towed and towing

vehicles become separated.

Figure 2

Figure 3