Bosch GEX 125-150 AVE Professional User Manual

Page 17

English | 17

Bosch Power Tools

2 609 932 821 | (26.10.11)

Preselecting the Orbital Stroke Rate

With the thumbwheel for preselection of the orbital stroke

rate 3, you can preselect the required orbital stroke rate, even

during operation.

The required stroke rate depends on the material and the

working conditions and can be determined through practical

testing.

After longer periods of working at low stroke rate, allow the

machine to cool down by running it for approx. 3 minutes at

maximum stroke rate with no load.

Sanding Plate Brake

An integrated sanding plate brake reduces the stroke rate

when running at no-load so that scoring is prevented when

placing the machine onto the workpiece.

If the no-load stroke rate continuously increases over the

course of time, then the sanding plate is damaged and must

be replaced or the sanding plate brake is worn. A worn sand-

ing plate brake must be replaced by an authorised after-sales

service agent for Bosch power tools.

Working Advice

f

Before any work on the machine itself, pull the mains

plug.

f

Wait until the machine has come to a standstill before

placing it down.

f

The power tool is not suitable for stationary operation.

For example, it may not be clamped in a vice or fastened on

a workbench.

Sanding Surfaces

Switch the machine on, place it with the complete sanding

surface on the surface to be worked and move the machine

with moderate pressure over the workpiece.

The removal capacity and the sanding pattern are mainly de-

termined by the selection of the sanding sheet, the preselect-

ed orbital stroke rate and the applied pressure.

Only flawless sanding sheets achieve good sanding capacity

and extend the service life of the machine.

Pay attention to apply uniform sanding pressure; this increas-

es the working life of the sanding sheets.

Intensifiying the sanding pressure does not lead to an in-

crease of the sanding capacity, but to increased wear of the

machine and the sanding sheet.

A sanding sheet that has been used for metal should not be

used for other materials.

Use only original Bosch sanding accessories.

Rough Sanding

Attach a sanding sheet with coarse grain.

Apply only light pressure to the machine so that it runs at a

higher stroke rate and high material removal is achieved.

Fine Sanding

Attach a sanding sheet with fine grain.

By lightly varying the application pressure or changing the or-

bital stroke rate, the sanding plate stroke rate can be reduced

whereby the orbital action is maintained.

With moderate pressure, move the machine in a circular pat-

tern or alternately in lengthwise and crosswise directions

over the workpiece. Do not tilt the machine to avoid sanding

through the workpiece (e. g. when sanding veneer).

After finishing the working procedure, switch the power tool

off.

Polishing

For the polishing of weathered paint or buffing out scratches

(e.g., acrylic glass), the machine can be equipped with appro-

priate polishing accessories such as lamb’s wool bonnet, pol-

ishing felt or sponge (accessories).

Select a low stroke rate (setting 1–2) for polishing in order to

avoid excessive heating of the surface.

Apply the polish onto a somewhat smaller surface than you in-

tend to polish. Work the polishing agent in with a suitable pol-

ishing tool applying it crosswise or with circular motion and

moderate pressure.

Do not allow the polishing agent to dry out on the surface, oth-

erwise the surface can become damaged. Do not subject the

surface to be polished to direct sunlight.

Clean the polishing accessories regularly to ensure good pol-

ishing results. Wash out polishing accessories with a mild de-

tergent and warm water; do not use paint thinner.

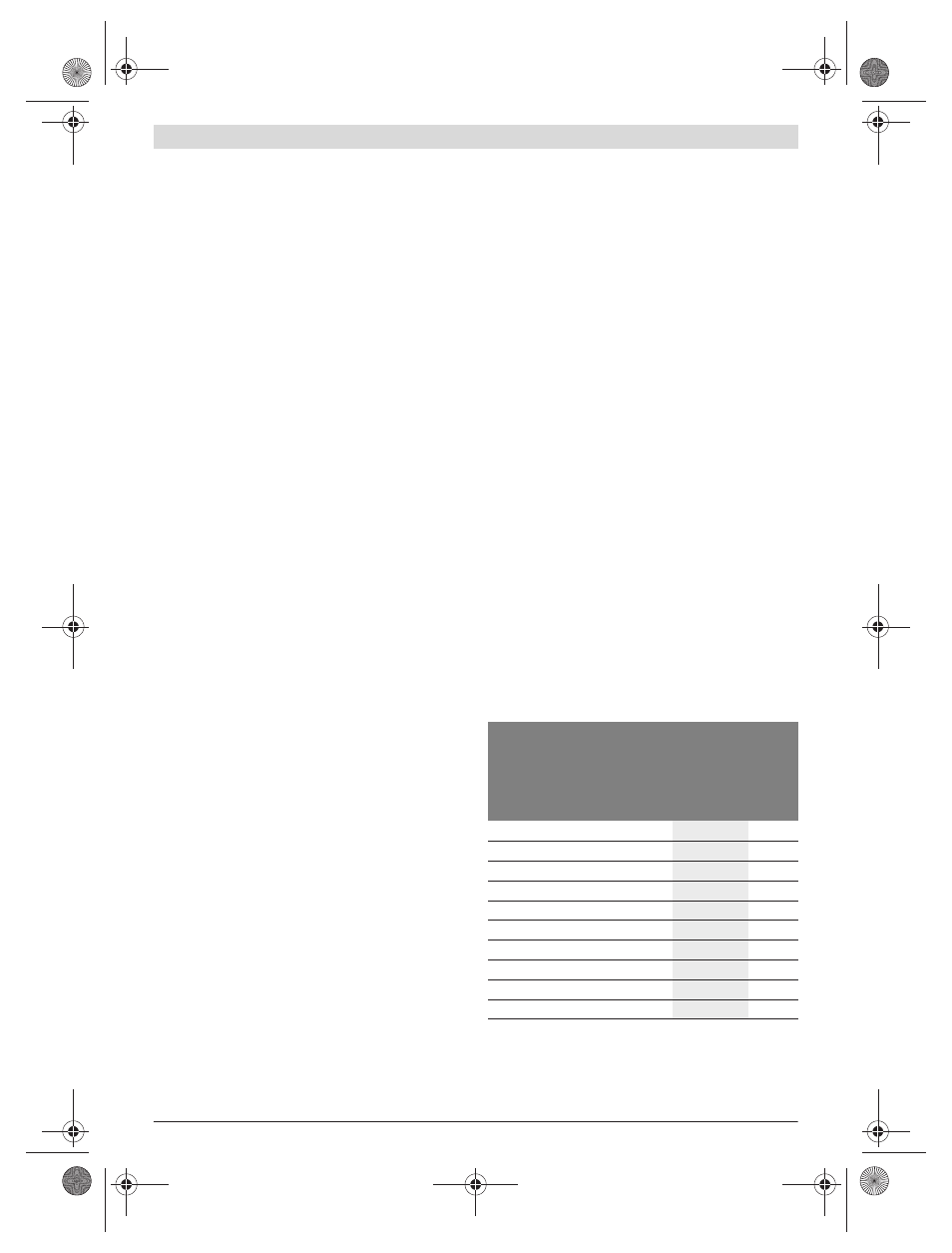

Application Table

The data in the following table are recommended values.

The most favourable combination for working is best deter-

mined by practical testing.

1–2 Low stroke rate

3–4 Medium stroke rate

5–6 High stroke rate

Application

Grain Size (course sanding/ fine sanding)

Oscillation Rate

Intermediate varnish sanding

120/400

5/6

Varnish/glaze

40/80

5/6

Softwood

40/240

5/6

Hardwood

60/320

5/6

Veneer

240/320

5/6

Aluminium

80/240

5

Steel

60/240

5

Derusting steel

40/120

6

Stainless steel

120/240

5

Masonry, stone

80/200

6

OBJ_BUCH-1330-003.book Page 17 Wednesday, October 26, 2011 11:52 AM