York YCAL0080SC User Manual

Page 106

YORK INTERNATIONAL

106

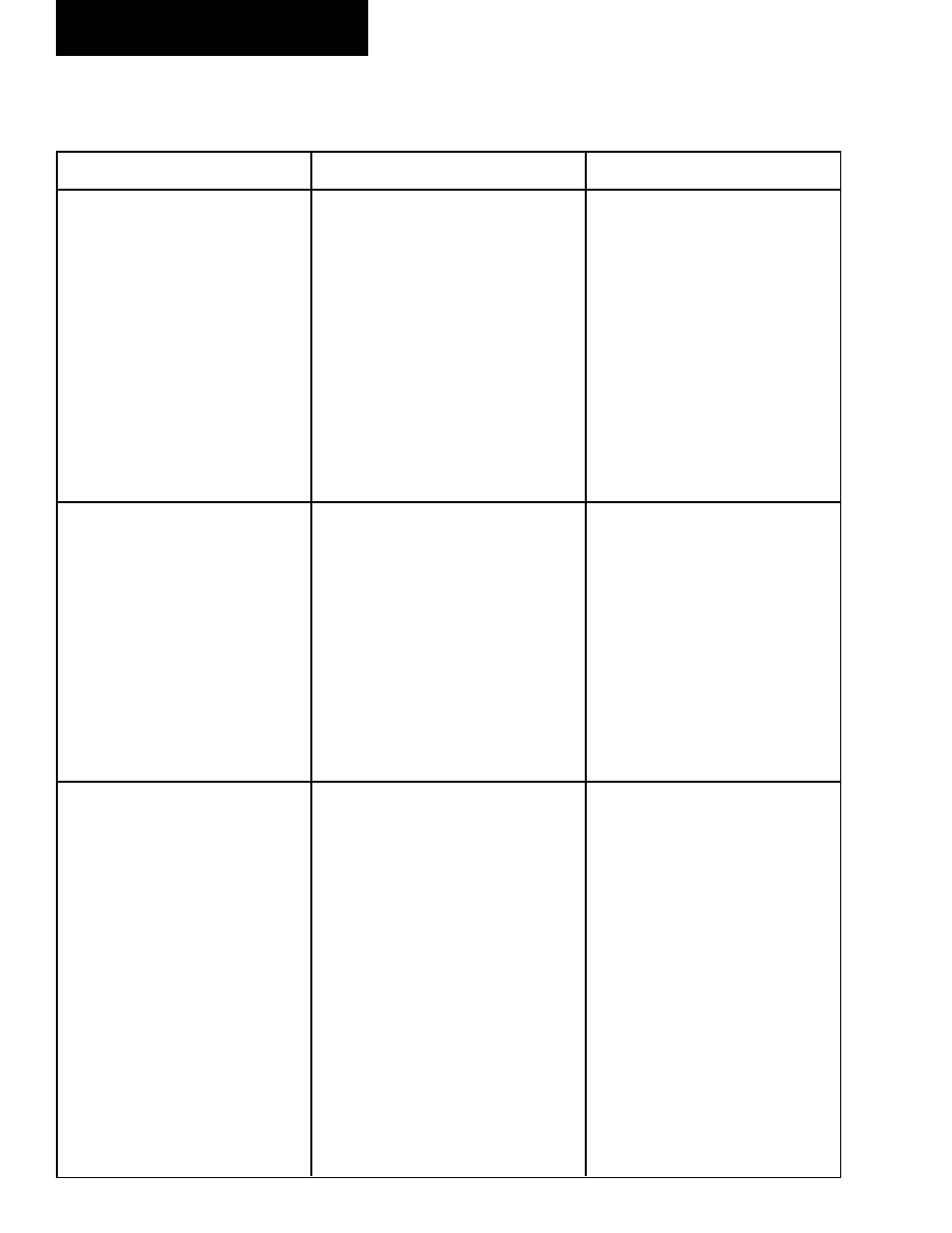

PROBLEM

CAUSE

SOL

“LOW SUCTION PRESSURE”

4. TXV defective.

4. Replace TXV.

FAULT (CONT’D)

5. Reduced flow of chilled

5. Check GPM (See “Limitations”

liquid through the cooler.

in Installation section). Check

operation of pump, clean

pump strainer, purge chilled

liquid system of air.

6. Defective suction pressure

6. Replace transducer/low

transducer/low pressure

pressure switch or faulty

switch or wiring

wiring. Refer to “Service”

section for pressure/voltage

formula.

7. LLSV defective

7. Replace LLSV

“HIGH DISCHARGE

1. Condenser fans not operating

1. Check fan motor, fuses,

PRESSURE” FAULT

or operating backwards.

and contactors. Assure fan

blows air upward.

2. Too much refrigerant.

2. Remove refrigerant.

3. Air in refrigerant system.

3. Evacuate and recharge

system.

4. Defective discharge

4. Replace discharge pressure

pressure transducer.

transducer. Refer to Service

section for pressure/voltage

formula.

“LOW LIQUID TEMP”

1. Improperly adjusted leaving

1. Re-program the leaving

FAULT

chilled liquid temp cut-out

chilled liquid temp. cut-out.

(glycol only).

2. Micropanel setpoint/range

2. Re-adjust setpoint/range.

values improperly programmed.

3. Chilled liquid flow too low.

3. Increase chilled liquid flow –

refer to Limitations in Instal-

lation section.

4. Defective LWT or RWT sensor.

4. Compare sensor against a

(assure the sensor is properly

known good temperature

installed in the bottom of the well

sensing device. Refer to

with a generous amount of heat

Service section for temp/

conductive compound)

voltage table.

CONT’D

Service and Troubleshooting