Warning, Maintenance, Flushing the unit – Wagner SprayTech 0295001 User Manual

Page 7: Daily maintenance

English

Always spray at minimum pressure with the gun nozzle tip

removed when using mineral spirits or any other solvent

to clean the pump, hose, or gun. Static electricity buildup

may result in a fire or explosion in the presence of

flammable vapors.

Flushing the Unit

Flush the unit with the solvent appropriate to the material

being used after daily use (use solvents at room temperature).

The unit should then be flushed again with mineral spirits.

For long term storage, flush the unit with an appropriate oil

before storing.

1. Follow the pressure relief procedure found earlier in this

manual.

2. Turn the PRIME/SPRAY

valve to SPRAY to bleed

off any pressure

remaining in the pump.

3. Remove the gun tip and

clean with a solution

appropriate to the type of

material being sprayed.

4. Remove the material

container and replace it with a container of solvent

appropriate to the type of material being sprayed.

5. Check to be sure the pressure control knob is turned fully

counterclockwise to its lowest setting.

6. Turn the power switch to ON.

7. Trigger the spray gun into a waste container until solvent

comes out and the pump, hose, and gun are clean.

8. Follow the pressure relief procedure found earlier in this

manual.

9. Make certain that the power switch is turned to OFF.

10. Turn the PRIME/SPRAY valve to SPRAY to bleed off any

remaining solvent.

11. Unplug the unit and store in a clean, dry area.

Maintenance

Daily Maintenance

Perform the following procedures daily.

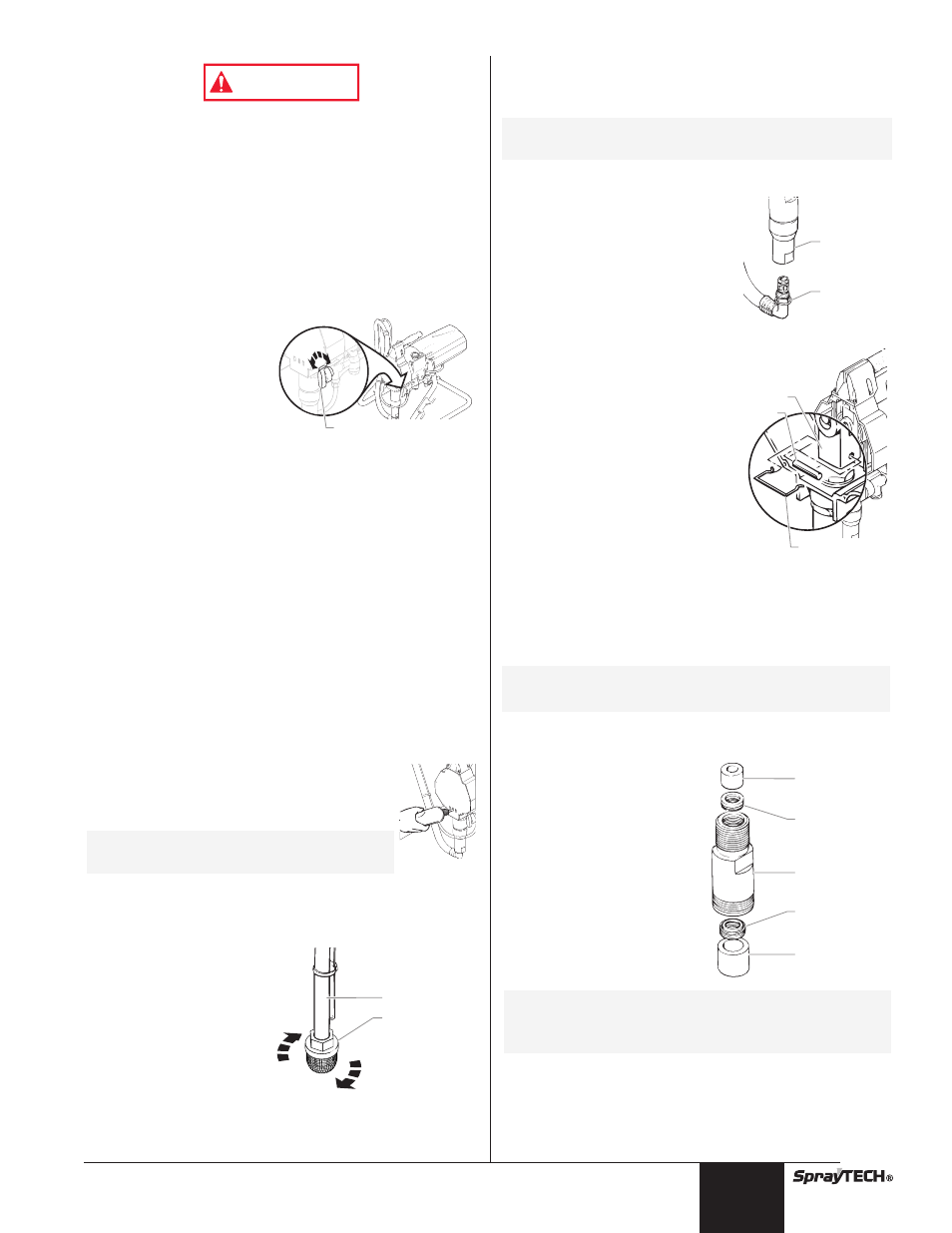

Filling the Packing Nut Reservoirs With Oil

Before you start to spray each day, squirt a

lubricant such as hydraulic oil into the slots in the

upper pump housing. Household oil and cooking

oil also work when hydraulic oil is not available.

This lubricant keeps the piston seals pliant, minimizing paint

bypass and piston wear. If the unit is operated several hours a

day, lubricate approximately every 4 hours.

Cleaning the Intake Screen

1. Remove the intake

screen and clean with a

solvent appropriate to

the type of material

being used.

Suction Set

Intake Screen

NOTE: Do not apply so much that it

overflows and drips into the paint.

SPR

AY

PRIME

S

P

R

A

Y

P

R

IM

E

PRIME/SPRAY Valve

WARNING

Maintaining the Fluid Section

Servicing the fluid section includes replacing the T-lip

packings, the piston, and valve parts that show signs of wear.

Removing the Fluid Section

1. Using a flat blade screwdriver, pry

the retaining ring out of the

bottom of the inlet valve housing

and remove the suction set

assembly.

2. Unscrew the fluid hose from the

fluid section assembly.

3. Loosen and turn the return line

fitting away from the fluid section

assembly.

4. Unscrew the 6 screws holding the

cover to the front of the pump

housing and remove the cover.

5. Pull the retaining clip from the

yoke and pin.

6. Push the pin out of the piston and

yoke. Use the short end of a hex

wrench if necessary.

7. Loosen the locknut at the top of

the fluid section assembly.

8. Unscrew the fluid section

assembly from the pump.

Maintaining the T-lip Packings

Removing the T-lip Packings

1. Place the wrench flats of the inlet valve housing into a

vise and unscrew the fluid section from the inlet valve

housing.

2. Unscrew the packing nut from the fluid section.

3. Push the piston out through the lower end of the fluid

section. Tap the top of the piston with a rubber mallet if

necessary.

4. Remove the upper and

lower spacers from the fluid

section.

5. Push the T-lip packings out

of the fluid section with a

screwdriver. To push out

the upper seal, insert the

screwdriver through the

lower end of the fluid

section. To push out the

lower seal, insert the

screwdriver through the

upper end of the fluid

section.

NOTE: When removing the T-lip packings, be careful

not to scrape or gouge the inside surface of the

fluid section with the screwdriver.

Fluid Section

Cylinder

Upper T-lip

Packing

Upper Spacer

Lower Spacer

Lower T-lip

Packing

NOTE: When removing the piston, keep the piston

from falling or the piston may be damaged.

Yoke

Pin

Retaining Clip

Retaining

Ring

Inlet Valve

Housing

NOTE: If any parts are difficult to disassemble, soak them

in an appropriate solvent until the paint softens.

© SprayTECH. All rights reserved.

7