Install water piping, Boiler manual – Weil-McLain ULTRA 80 EN User Manual

Page 18

Part number 550-101-233/0903

GAS

-

FIRED

WATER

BOILER

— Boiler Manual

18

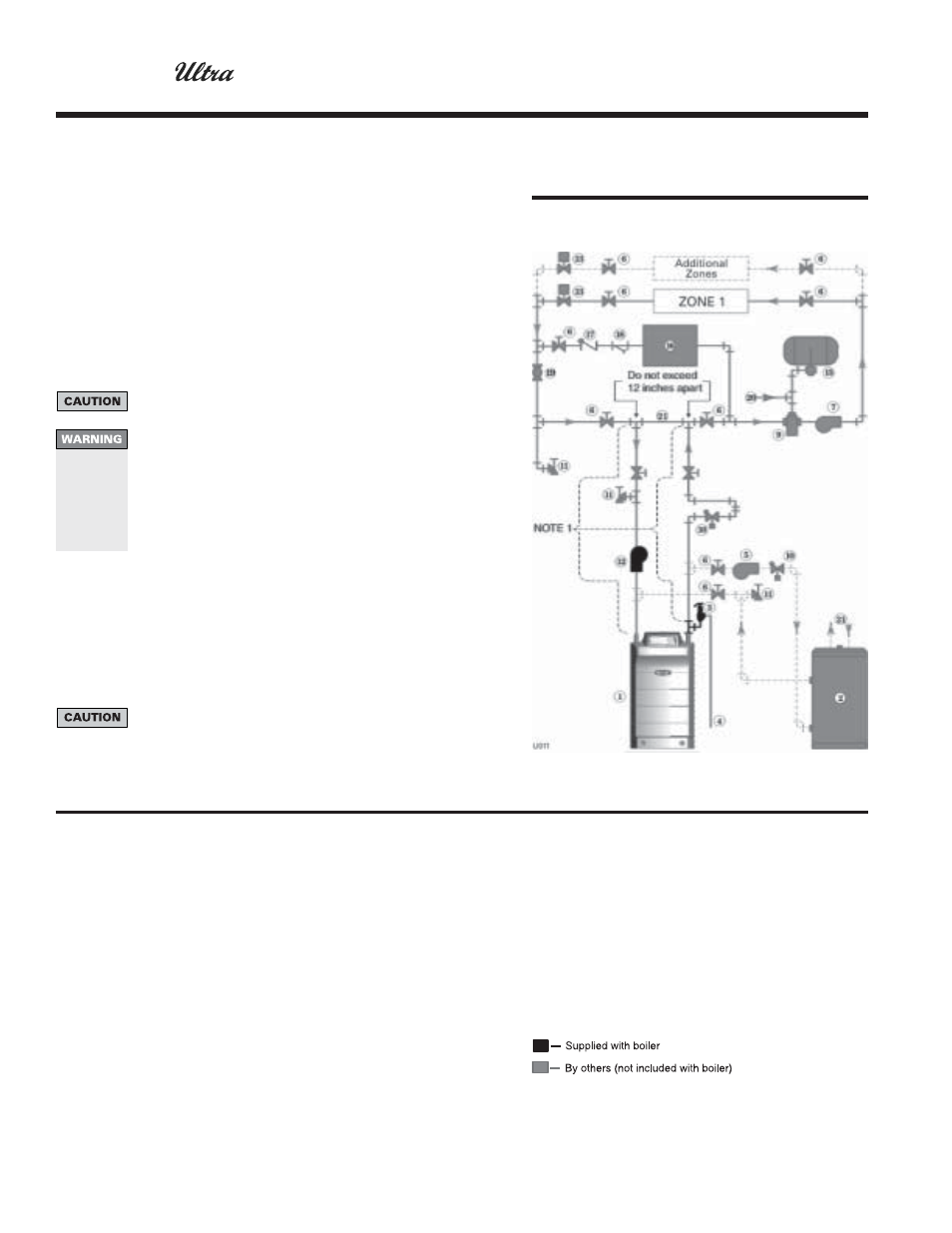

Chilled water systems

1. Install boiler so that chilled medium is piped in parallel with the heating

boiler. Use appropriate valves to prevent chilled medium from entering

boiler. See Figure 10 for typical installation of balancing valve and check

valve.

2. The space heating system may be zoned with circulators if a separate

circulator is supplied for the chilled water loop.

3. If boiler is connected to heating coils located in air handling units where

they can be exposed to refrigerated air, use flow control valves or other

automatic means to prevent gravity circulation during cooling cycle.

Follow these piping guidelines below to ensure chilled water

does not enter the boiler loop.

Chilled medium, if used, is piped in parallel with heating boiler

as shown in Figure 10. Use appropriate valves to prevent chilled

medium from entering boiler.

If boiler is connected to heating coils located in air handling

units where they can be exposed to refrigerated air, use flow

control valves or other automatic means to prevent gravity

circulation during cooling cycle.

Figure 10

Chilled water system plus optional

DHW piping

Legend

Figure 10

Install water piping

(continued)

3

1

Ultra boiler

2

Indirect water heater (DHW), if used

3

Boiler relief valve (see page 12 for piping details)

4

Relief valve discharge piping (see page 12 for details)

5

DHW circulator (see page 14 for suggested sizing)

6

Isolation valves

7

System circulator

9

Air separator (DO NOT use automatic air vents on systems fitted with closed-

type tanks)

10 Flow/check valves (with weighted seats to prevent gravity circulation)

11 Purge/drain valves

12 Boiler circulator

13 Zone valves, typical

15 Closed-type expansion tank

16 Water chiller

17 Check valve

18 Strainer

19 Balancing valve

20 Make-up water supply

21 Primary/secondary connection

NOTE 1:

To ensure adequate flow rate through the boiler, use the following

pipe size on all boiler loop piping (connecting boiler to and from

the primary/secondary connection, item 21):

Ultra-80 or Ultra-105 – 1" or larger.

Ultra-155 or -230 – 1¼" or larger.

Ultra-310 – 1½" or larger.

Use at least the minimum piping size above and pipe the boiler

using only primary/secondary piping as shown. Failure to

follow these guidelines could result in system problems.