Verify proper operation after servicing – Weil-McLain SERIES 7 PFG User Manual

Page 11

11

PFG S

erieS

7 G

aS

-

Fired

W

ater

B

oiler

– U

niverSal

C

ontrol

S

yStemS

Part Number 550-110-643/0605

VERIFY PROPER OPERATION AFTER SERVICING

Never jumper (bypass) any device except

for momentary testing as outlined in

Troubleshooting Charts. Substantial

property damage and/or severe personal

injury could occur.

Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation.

1. Before troubleshooting.

a. Have a voltmeter that can check 120VAC, 24VAC, a

microammeter with minimum scale range of 0-25, and a

continuity tester.

b. Check for 120VAC (min. 102 - max. 132) to boiler.

c. Check for 24VAC at secondary side of transformer.

d. Make sure thermostat is calling for heat and contacts

(including appropriate zone controls) are closed. Check for

24VAC between thermostat wire nuts and ground.

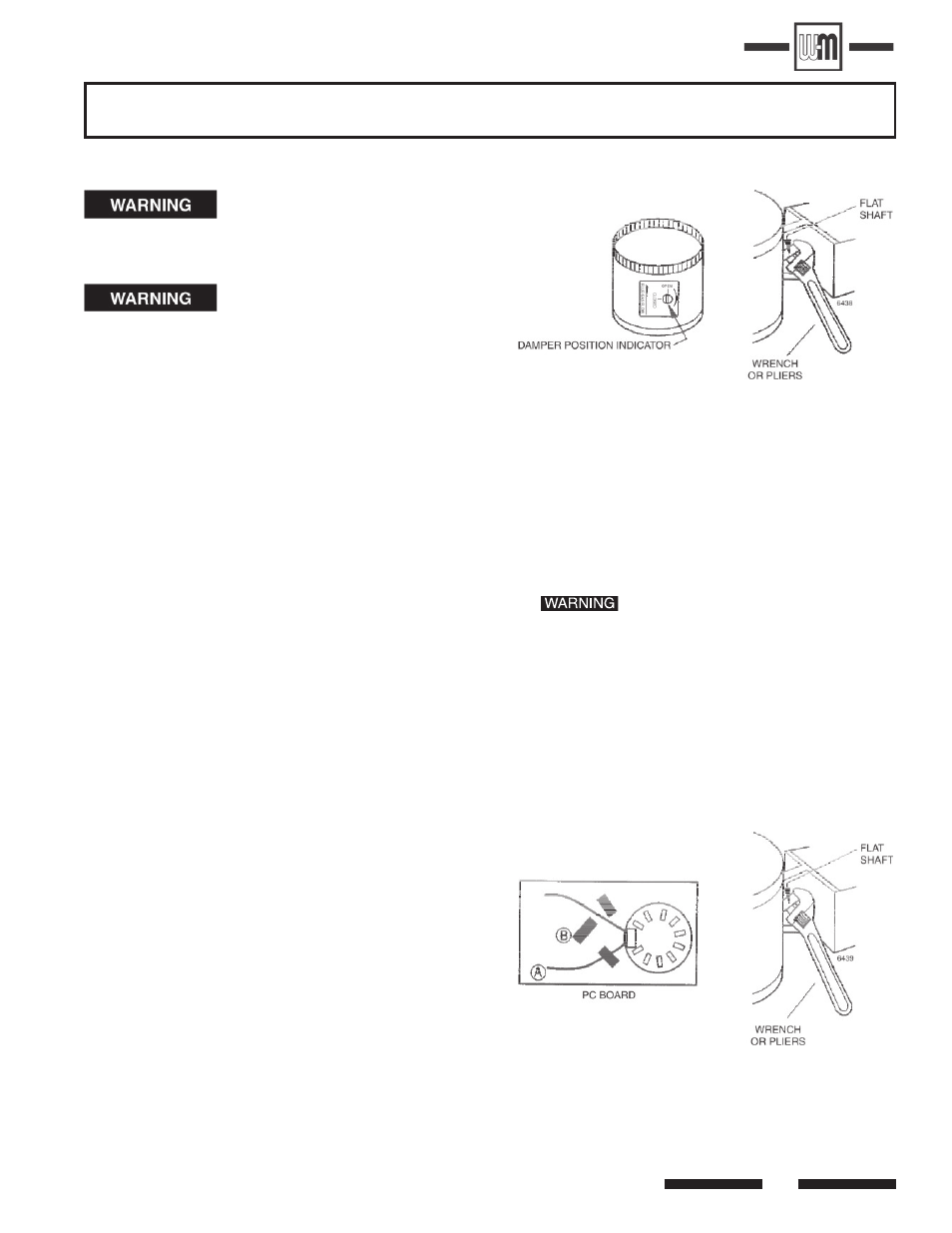

IN EVENT OF ACTUATOR FAILURE

–EFFIKAL DAMPER

If troubleshooting chart recommends replacing actuator, and

actuator is not immediately available, damper blade can be

fixed in an open position to allow boiler operation.

Manually turning blade can cause actuator damage. Follow these

instructions only in case of no heat or damper actuator malfunc-

tion. See Figure 6.

1. Move damper service switch to “HOLD DAMPER OPEN”

position. Apply “call for heat” to boiler. Damper blade should

then rotate to open position and boiler will fire.

2. If Step 1 above does not open damper, manually rotate

damper blade to open position using wrench or pliers on flat

shaft between damper and actuator. Boiler will fire. Verify

that damper service switch is in “HOLD DAMPER OPEN”

position.

3. Do not leave damper permanently in this position. Replace

actuator immediately. If damper is left in open position, boiler

will not operate at published efficiencies.

See damper manufacturer’s instructions packed with

damper for additional information.

JOHNSON DAMPER

If troubleshooting chart recommends replacing actuator, and

actuator is not immediately available, damper blade can be fixed

in open position to allow boiler operation. Follow these instruc

-

tions only in case of no heat or damper actuator malfunction.

See Figure 7.

1) Turn off power to boiler.

Failure to turn off power to boiler can result

in severe personal injury, death or substantial

property damage.

2) Remove damper actuator cover.

3) On PC board, move wire from A to B.

4) Turn on power to boiler.

5) Using wrench or pliers on flat shaft section, manually rotate

damper blade until green light turns on. Boiler will fire.

6) Do not leave damper permanently in this position. Replace

actuator immediately. If damper is left in open position, boiler

will not operate at published efficiencies.

See damper manufacturer’s instructions packed with

damper for additional information.

Figure 7

Figure 6

Section D: Troubleshooting