Installation, Horizontal installations – Waterford Appliances T25-LP User Manual

Page 12

12

Waterford TARA T25 Direct Vent Freestanding Gas Stove

Diagram 4

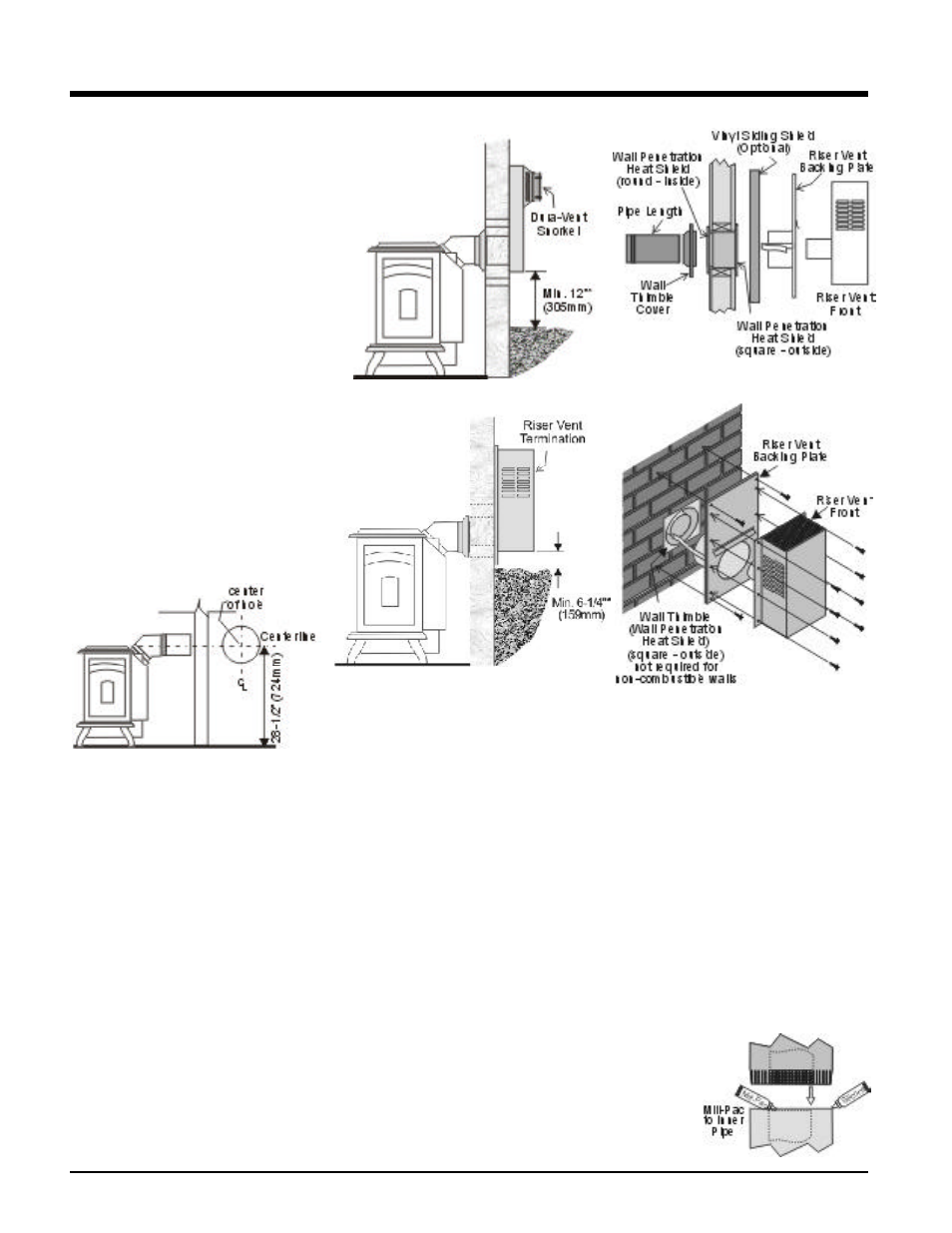

Diagram 2a

Diagram 3

HORIZONTAL

INSTALLATIONS

1) Set the unit in its desired location. Check to

determine if wall studs are in the way when

the venting system is attached. If this is the

case, you may want to adjust the location

of the unit.

2) Assemble the desired combination of pipe

and elbow to the appliance adapter with

pipe seams oriented down. Offset the pipe

seams as double seams in one place will

cause the outer pipe to take an oval shape.

Kit comes complete with 18" of straight vent

- 6-5/8" dia. black outer pipe and 4" dia. inner

vent.

3) With the pipe attached to the stove, slide the

stove into its correct location, and mark the

wall for a 9-1/2" (inside dimensions) round

hole. The center of the round hole should

line up with the centerline of the horizontal

pipe, as shown in diagram 1. Cut and frame

the 9-1/2 round hole in the exterior wall

where the vent will be terminated. If the wall

being penetrated is constructed of non-

combustible material, i.e. masonry block or

concrete, a 7" diameter hole is acceptable.

Note:

a) The horizontal run of vent should have a 1/

4 inch rise for every 1 foot of run towards

the termination. Never allow the vent to run

downward. This could cause high temper-

atures and may present the possibility of a

fire.

b) The location of the horizontal vent termina-

tion on an exterior wall must meet all local

and national building codes, and must not be

blocked or obstructed. For External Vent

Terminal Locations, see diagram on page 9.

c) Snorkel Terminations:

For installations requiring a vertical rise on

the exterior of the building, 14-inch and 36-

inch tall Snorkel Terminations as shown in

Dia. 2 are available, as well as the standard

Riser Vent. Follow the same installation

procedures as used for standard Horizon-

tal Termination. NEVER install the snorkel

upside down.

Diagram 1

*Dia 2a & 2b: As speci-

fied in CGA B149 Instal-

lation Code. Local codes

or regulations may re-

quire different clearanc-

es.

NOTE: For Snorkel terminations in ABOVE

grade installations, follow national

or local code requirements.

Below Grade Snorkel Installation

If the Snorkel Termination must be installed

below grade, i.e. basement application,

proper drainage must be provided to pre-

vent water from entering the Snorkel Ter-

mination. Refer to Dura-Vent Installation

instructions for details.. Do not attempt to

enclose the Snorkel within the wall, or any

other type of enclosure.

4) Install wall penetration heat shield in the

center of the 9-1/2" round hole and attach

with wood screws. The four wood screws

provided should be replaced with appropri-

ate fasteners for stucco, brick, concrete,

or other types of sidings. Dia. 3.

5) If installing termination on a siding covered

wall, a vinyl siding standoff or furring strips

must be used to ensure that the termination

is not recessed into the siding. Dia. 3.

6) Take the Riser Vent terminal and separate

the Backing Plate from the Riser Vent Front

by removing 8 screws as shown in dia-

gram 4.

INSTALLATION

Diagram 2b

7) Install the Backing Plate into the wall pene-

tration heat shield and attach using 4

screws. Dia. 4.

8) Connect all pipe sections to unit and install

into wall:

a) Measure pipe length required and cut to

length. Hint: use the cut end of the 6-5/8" dia.

outer pipe at the vent terminal end.

b) Push the pipe sections completely together,

the minimum pipe overlap is 1-1/4". Secure

all outer pipe joints by using at least two

screws. Locate the screws at the bottom

of the pipe so that the screw heads are

hidden on the final installation. Apply seal-

ant "Mill-Pac" to inner pipe and high temp

silicone sealant or "Mill-Pac" to outer pipe on

every joint.

Hint: Apply sealant

to female end.