Installation – Waterford Appliances T25-LP User Manual

Page 22

22

Waterford TARA T25 Direct Vent Freestanding Gas Stove

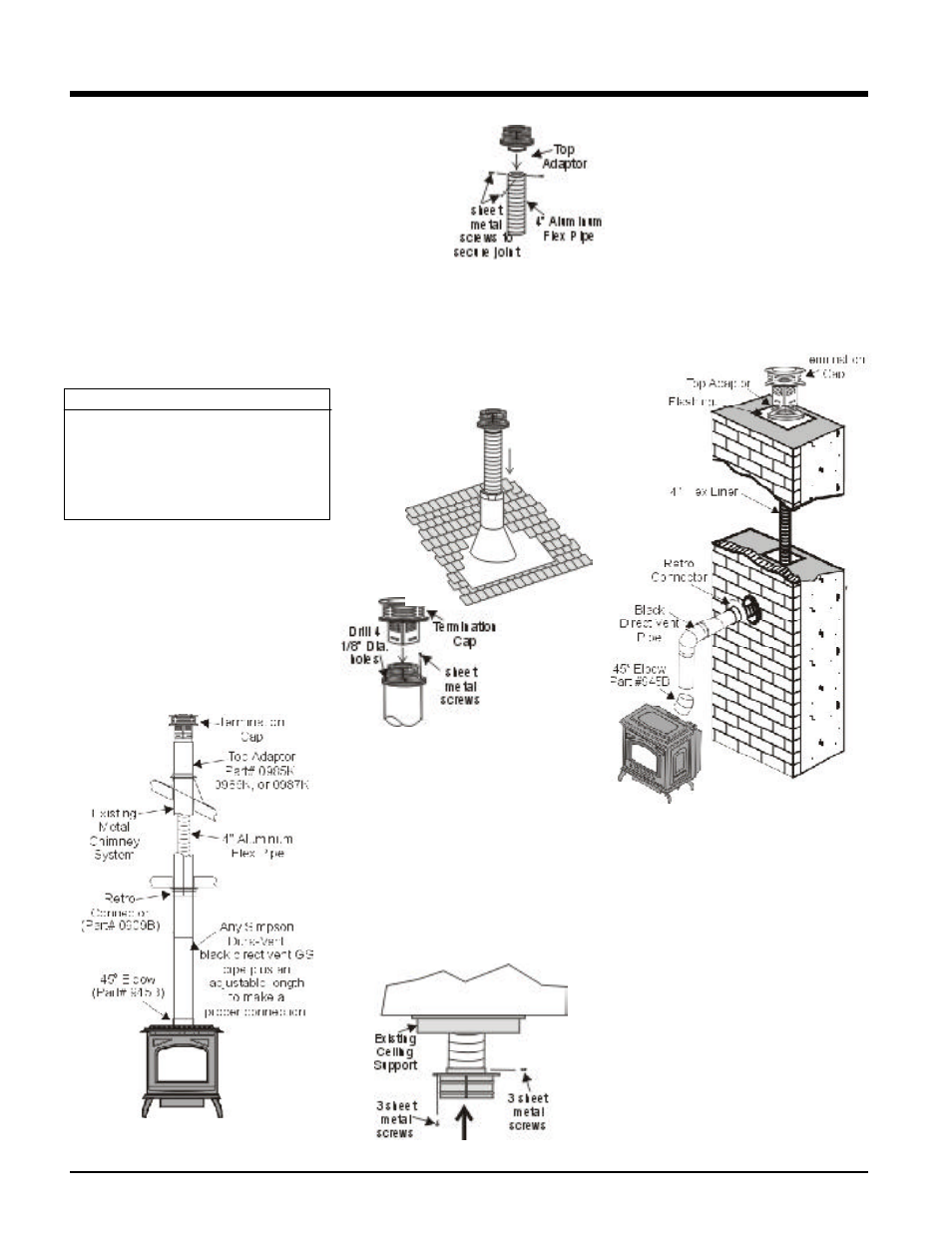

Converting a Masonry Chimney

Important: The existing masonry flue

opening needs to have an area of at least

a 36 sq. in. to insure proper intake/ex-

haust flow.

1) Before cutting any holes, assemble the

desired sections of black direct vent pipe to

determine the center of the masonry pene-

tration.

Diagram 6

2) Once the center point of the penetration has

been determined, cut a 6" (152mm) dia. hole

in the masonry. Be careful, if the hole is too

large, the Retro Connector might not mount

properly, and if the hole is too small, then the

appliance might starve for intake air. If there

is a frame wall in front of the masonry wall,

cut and frame a 10" (254mm) clear square

opening in the wall (centered around the 6"

(152mm) masonry opening). IF there is

sheet rock only (no studs) in front of the

masonry, the 10" (254mm) clear opening is

still needed, but does not need to be framed.

This allows the Retro Connector to mount

directly on the masonry and provide clear-

ance to the combustibles. Diagram 11.

3) Secure the Flashing (Part # 705C) to the top

of the masonry chimney using a bead of

non-hardening sealant-adhesive. If the

Flashing is larger than the top of the chim-

ney, then cut and fold flashing as needed

to fit chimney. Diagram 7.

Diagram 3

Diagram 4

Diagram 5

4) Pass the flex pipe down through the center

of the chimney system, and center the

adaptor on the top of the chimney pipe. Drill

four 1/8" diameter holes through the adap-

tor and into the chimney top. Insure that you

are in fact, drilling into the metal on the

chimney. Twist-lock the Termination Cap

(Part# 980 or 991) onto the Adaptor. (Dia-

gram 3 and 4).

5) Pull the flex pipe down through the ceiling

support box, until it protrudes approximate-

ly 3" (76mm). Connect the flex pipe to the

Retro Connector by slipping it into the

4-3/4" diameter sleeve on the top side of the

Connector. Use 3 sheet metal screws to

assemble these two parts.

6) Push the flex pipe back up into the ceiling

support box, center the Retro Connector,

and attach it to the support box, or decora-

tive sleeve for double wall solid packed

pipe, with the sheet metal screws (sup-

plied). The holes in the Retro Connector are

pre-punched. Diagram 5.

7) The connection between the appliance and

the Retro Connector may be completed

with sections of black direct vent pipe,

together with an adjustable length.

3) Connect the end of the

flex pipe section to the

underside of the Top

Adaptor using 3 sheet

metal screws.

Diagram 2.

Diagram 1

Diagram 2

The direct vent system must not be con-

nected to a damaged factory-built or ma-

sonry chimney.

For factory built, zero clearance, and ma-

sonry chimneys cleanout doors and caps

or plugs for cleanout tee fittings and ash

dumps shall be secured in place and

sealed before installing a Direct Vent

system within the chimney.

If the appliance shuts off during opera-

tion, contact a qualified service person to

determine if a negative pressure and/or

leaky chimney condition exists. Do not

operate the appliance until the problem

is corrected.

Approved for US Installations Only

The use of an existing chimney as an air

intake is not covered under the ANSI

Z21.88b-1999, CSA 2.33b-M99 test meth-

ods and the resulting ITS/WHI product

certification. The code Authority Having

Jurisdiction must be consulted prior to

proceeding with this installation method.

Converting a Factory Built

Metal Chimney

1) Remove the existing chimney cap.

2) Measure the distance from the top end of

the chimney to the bottom of the ceiling

support box, add 3" (76mm) to this meas-

urement, and cut a section of the 4" flex pipe

to that length (the flex should already be

extended to its nominal length).

INSTALLATION