Utica Gas-fired Boiler User Manual

Page 20

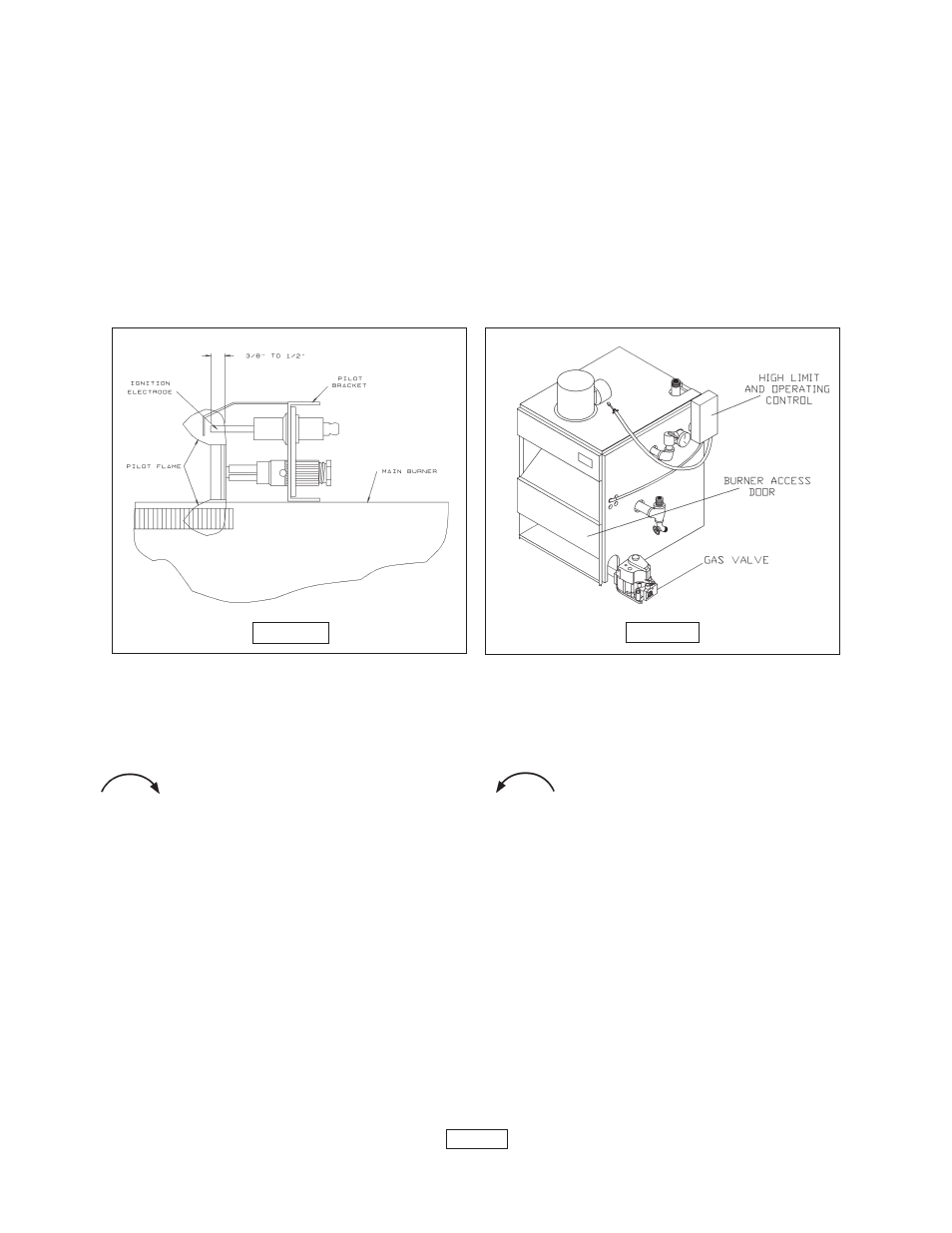

The burners and pilot should be checked for signs of corrosion, rust or scale buildup.

The area around the boiler must be kept clear and free of combustible materials, gasoline

and other flammable vapors and liquids.

The free flow of combustion and ventilating air to the boiler and boiler room must not be

restricted or blocked.

It is recommended that a qualified service agency be employed to make an annual

inspection of the boiler and heating system. They are experienced in making the inspections

outlined above, and, in the event repairs or corrections are necessary, trained technicians

can make the proper changes for safe operation of the boiler.

PAGE 19

FIGURE 22

FIGURE 21

CHECKING GAS INPUT RA

CHECKING GAS INPUT RA

CHECKING GAS INPUT RA

CHECKING GAS INPUT RA

CHECKING GAS INPUT RATE

TE

TE

TE

TE T

T

T

T

TO BOILER

O BOILER

O BOILER

O BOILER

O BOILER

Gas input to the boiler can be adjusted by removing the protective cap on the pressure

regulator, (See figures 14, 15, & 16 on pages 14 & 15), and turning the screw clockwise

to increase input and counterclockwise

to decrease input. Natural gas

manifold pressure should be set at approximately 3.5 inches water column. Propane gas

manifold pressure should be set at approximately 11.0 inches water column. These manifold

pressures are taken at the outlet side of the gas valve. See figures15 & 17 on pages14 &

15. To check for proper flow of natural gas to the boiler, divide the input rate shown on the

rating plate by the heating value of the gas obtained from the local gas company. This will

determine the number of cubic feet of gas required per hour. With all other gas appliances

off, determine the flow of gas through the meter for two minutes and multiply by 30 to get

the hourly rate. Make minor adjustments to the gas input as described above.

Burner orifices should be changed if the final manifold pressure varies more than plus or

minus 0.3 inches water column from the specified pressure.

Primary air adjustment is not necessary, therefore air shutters are not furnished as standard

equipment. Air shutters can be furnished on request where required by local codes or

conditions.