Meets or exceeds your specifications, W7 specifications – Toshiba W7 Series User Manual

Page 5

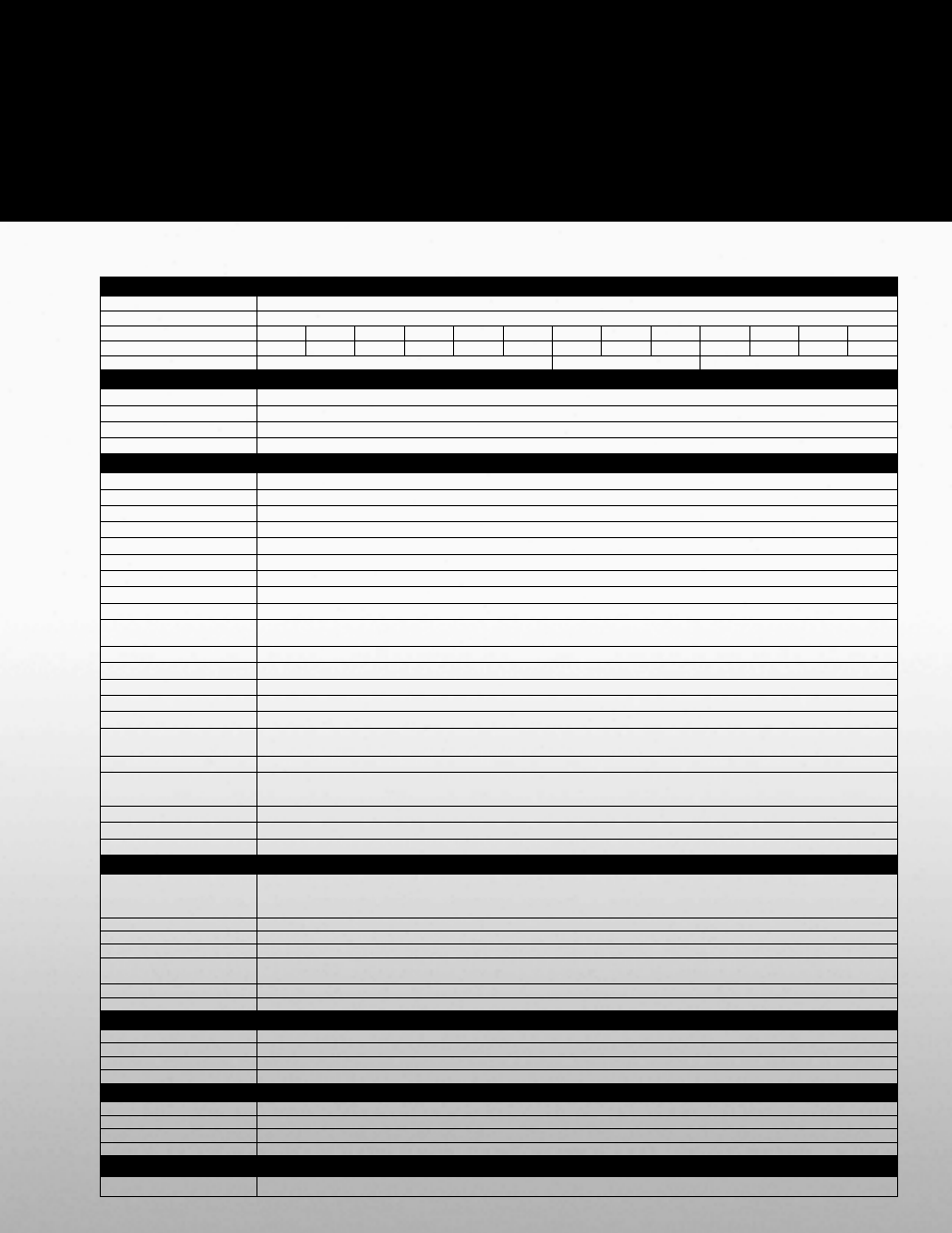

Meets or Exceeds

Your Specifications

Standard Specifications

Item

Voltage Class

460V

Maximum HP

60

75

100

125

150

200

250

300

400

500

600

700

800

Drive Rating (A)

77

96

124

156

190

240

302

370

480

628

753

879

1004

Dimensions

100”H x 30”W x 24”D

100”H x 42”W x 24”D

Consult Factory

Power Requirements

Output Frequency

0 – 400 Hz

Main Circuit

Three Phase 460V input auto-transformer 18 pulse design with circuit breaker, IGBT output.

Control Power

DC bus control power

Tolerance

Voltage: ±10% Frequency: ±2%

Control Specifications

Control Method

Sine Wave PWM System – Flux Field Current Vector Control

V/Hz Control

Constant Torque, Variable Torque, Open Loop Vector, Auto or Manual Torque Boost, 5 point V/Hz custom curves

Overload Rating

120% for 60 seconds, 100% continuous

Frequency Setting

Encoder Potentiometer integrated into EOI, 0-10V, ±10V, 4-20mA, Binary Input, Motorized Potentiometer Input

Frequency Precision

Analog Input: ±0.2% of maximum output frequency. Digital Input: ±0.01% of maximum output frequency

Frequency Resolution

0.01 Hz – Operation Panel. 0.1 Hz – Analog Input. 10-12 bit A-D converter

Acceleration / Deceleration

0.1~6000 seconds

Speed Regulation

Up to 0.1%, 60:1 speed range

Torque Regulation

10%; less than 3% ripple from 50 to 100% range

Set Point Control (PID)

Proportional Gain, Integral Gain, Feedback Settings Upper/Lower Deviation Limits, Feedback Source Delay Filter, Feedback

Settings Differential Gain

Analog Inputs

Four programmable: (1) 4-20mA, (1) 0-10V, (1) -10 to +10V, (1) 1 to 10kOHM potentiometer connection

Analog Outputs

Two programmable to 31 functions

Digital Inputs

Eight programmable to 67 functions

Output Contacts

Three output terminals, programmable to 52 functions. Form C contacts rated 250V AC, 2 amps inductive

Signal Isolation

Available (3) channel signal isolation for AM/FM outputs and II terminal input, rated at 750V

Control Board

Communication Ports

RS232 / 485 and TTL ports standard

Data Transmission

Profibus, Devicenet, Modbus RTU, Modbus+, Metysys, TCP/IP Ethernet. (Some devices are external)

Main Protective

Functions

Current limit, overcurrent, overvoltage, undervoltage, overtorque, load side short circuit, load side ground fault, heatsink

overheat, ASD overload, motor overload, armature short, CPU error, open output phase, communications error, loss of feedback

Soft Stall

Automatic load reduction control during overload

Retry

Can automatically clear fault upon trip. Programmable to 10 tries, with up to 10 seconds between tries.

Restart

Restart into a rotating motor

Interface

LCD EOI (Liquid Crystal

Display / Electronic

Operator Interface)

4 lines x 20 characters. Backlit LCD Display. Ability to display multiple parameters on one screen. Keypad may be operated from

an external power source. Software is flash upgradeable. Includes multi-function rotary encoder.

LED Indicators

Run (Red) / Stop (Green), Remote / Local (Green), DC bus charge indication (red)

Keys

Local /Remote, Monitor / Program, Run, Enter, ESC, Stop / Reset, Up, Down

Monitoring

Main display shows two monitored items continuously, or scrolls up to 40 items.

Selectable Display Units

User selectable and configurable, along with scaling factor multiplier. Voltage display selectable: Amps or %,

Current display selectable: Amps or %.

EOI Communication Ports

RS232 / 485 and TTL ports standard

Remote Mount Display

Remote mountable up to 1000ʼ

Construction

Enclosure

NEMA 1, IP20, Gasketed and Filtered

Panel Construction

Free standing, front maintenance type, top or bottom access for motor and power cables

Cooling

Forced air cooled. Top-mounted fans may be removed for movement during shipment or installation.

Color

ANSI-61 Gray

Ambient Conditions

Ambient Temperature

0 - 40°C, 32 - 104°F

Humidity

Max. 95% (non-condensing)

Altitude

1000 m (3300 ft) above sea level or less

Installation

Indoor, no direct sunlight, protect for corrosive gases, explosive gases

Standards

Electrical Performance

NEC, ANSI

W7 Specifications