Mechanical requirements installation, Refrigerant piping (air-cooled units only), Warning – Trane SCWH User Manual

Page 18: Electrical requirements

18

PKG-SVX14A-EN

mechanical

requirements

Installation

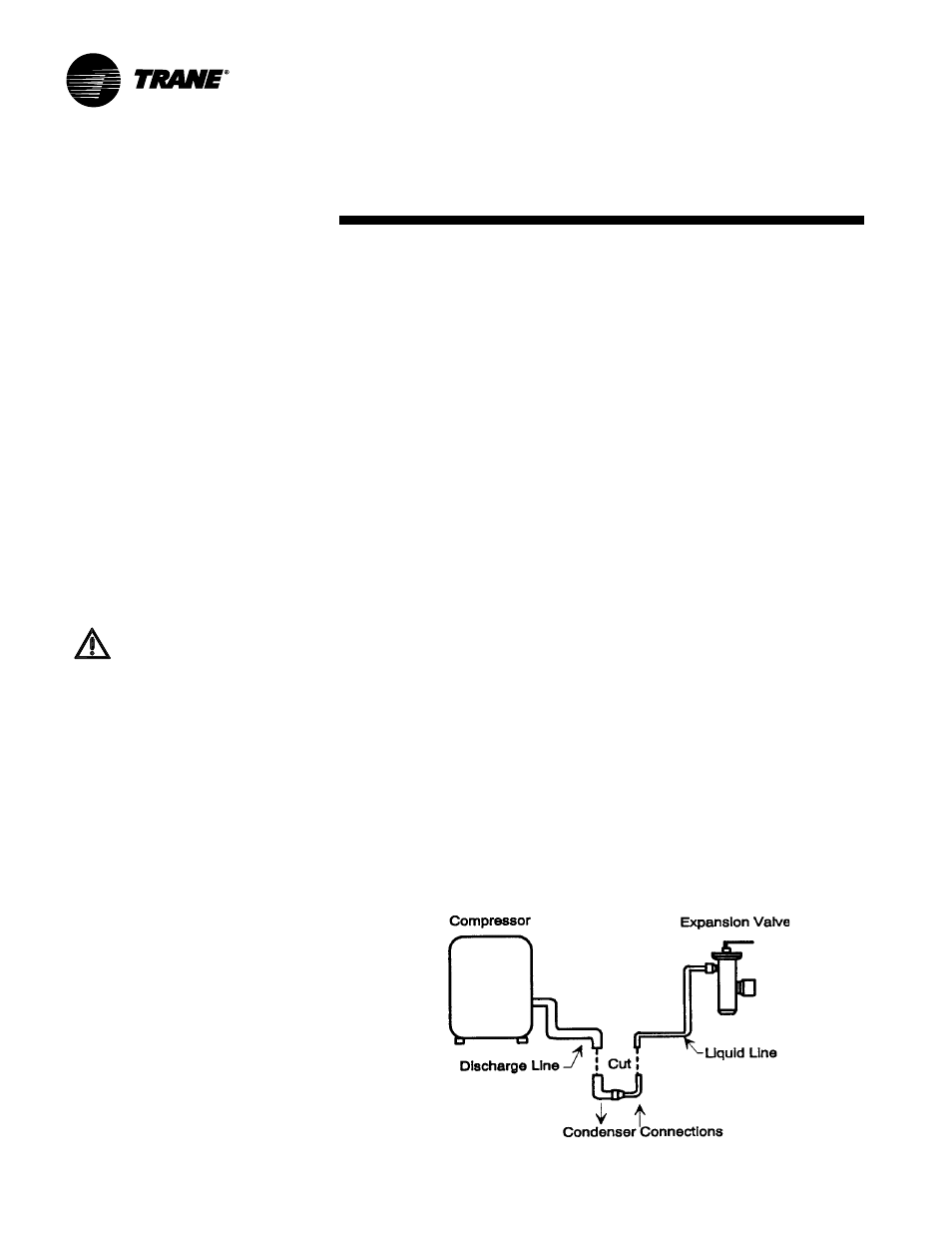

Refrigerant Piping (Air-Cooled

Units Only)

Reference industry recommendations

for air-cooled unit refrigerant piping. If

suspending piping from the building, use

isolation hangers to prevent vibration

transmission.

Air-cooled units ship with a holding

charge of nitrogen. Before installing unit

piping, momentarily depress either the

suction or discharge line access valve to

verify that the holding charge has not

been lost. If nitrogen does not escape

when depressing the access valve, leak-

test the entire refrigerant system to

determine the source of loss.

The charge is contained by a continuous

loop of both hot gas and liquid lines. You

must cut the loop for connection to

discharge and liquid lines. See Figure I-

MR-1.

Brazing Procedures

Proper brazing techniques are essential

when installing refrigerant piping. Keep

the following factors in mind when

making sweat connections.

1. When heating copper in the presence

of air, copper oxide forms. To prevent

copper oxide from forming inside the

tubing during brazing, sweep an inert

gas, such as dry nitrogen, through the

tubing. Nitrogen displaces air in the

tubing and prevents oxidation of

interior surfaces. A nitrogen flow of one

to three cubic feet per minute is

sufficient to displace the air. Use a

pressure regulating valve or flow meter

to control the flow.

2. Ensure tubing surfaces that require

brazing are clean and the ends of the

tubes are carefully reamed to remove

any burrs.

3. Make sure the inner and outer tubes of

the joint are symmetrical and have a

close clearance, providing an easy slip

fit. If the joint is too loose, the tensile

strength of the connection will be

significantly reduced. Make the overlap

distance equal to the inner tube

diameter.

4. Wrap the body of each refrigerant line

component with a wet cloth to keep it

cool during brazing. Excessive heat can

damage the components.

5. If using flux, apply it sparingly to the

joint. Excess flux will contaminate the

refrigerant system.

6. Apply heat evenly over the length and

circumference of the joint, making sure

the entire joint becomes hot enough to

melt the brazing material.

7. Begin brazing when the joint is hot

enough to melt the brazing rod. The hot

copper tubing, not the flame, should

melt the rod.

8. Continue to apply heat around the joint

circumference until the brazing material

is drawn into the joint by capillary

action, making a mechanically sound

and gas-tight connection.

9. Visually inspect the connection after

brazing to locate any pin holes or

crevices in the joint. Use a mirror to

inspect connections that are difficult to

see.

Figure I-MR-1. Air-cooled unit refrigerant piping

WARNING:

Hazard of Explosion and Deadly

Gases!

Never solder, braze or weld on

refrigerant lines or any unit com-

ponents that are above atmo-

spheric pressure or where

refrigerant may be present.

Always remove refrigerant by fol-

lowing the guidelines estab-

lished by the EPA Federal Clean

Air Act or other state or local

codes as appropriate. After refrig-

erant removal, use dry nitrogen to

bring system back to atmospheric

pressure before opening system

for repairs. Mixtures of refriger-

ants and air under pressure may

become combustible in the pres-

ence of an ignition source leading

to an explosion. Excessive heat

from soldering, brazing or weld-

ing with refrigerant vapors

present can form highly toxic

gases and extremely corrosive

acids. Failure to follow all proper

safe refrigerant handling prac-

tices could result in death or seri-

ous injury.

Electrical Requirements

Follow these guidelines, referring to unit

wiring diagrams and supply power

dimensional information to ensure

correct electrical requirements at the

installation site. Reference supply power

wiring locations on unit submittals orin

the “Dimensions and Weights” section.

Specific unit wiring diagrams are

provided on each unit. Use these

diagrams for connections or trouble

analysis.

Unit Wiring Diagrams

Specific unit wiring diagrams are

provided on the inside of the control

panel door. Use these diagrams for

connections or trouble analysis.