Maintenance and repair instructions – Troy-Bilt TB90BC User Manual

Page 17

MAINTENANCE AND REPAIR INSTRUCTIONS

17

WARNING: To prevent serious injury, never

do maintenance or repairs with unit running.

Always do maintenance and repairs on a

cool unit. Disconnect spark plug wire to

ensure the unit will not start.

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about

these procedures take your unit to an authorized

service dealer.

MAINTENANCE SCHEDULE

These required maintenance procedures should be

performed at the frequency stated in the table. They

should also be included as part of any seasonal tune-up.

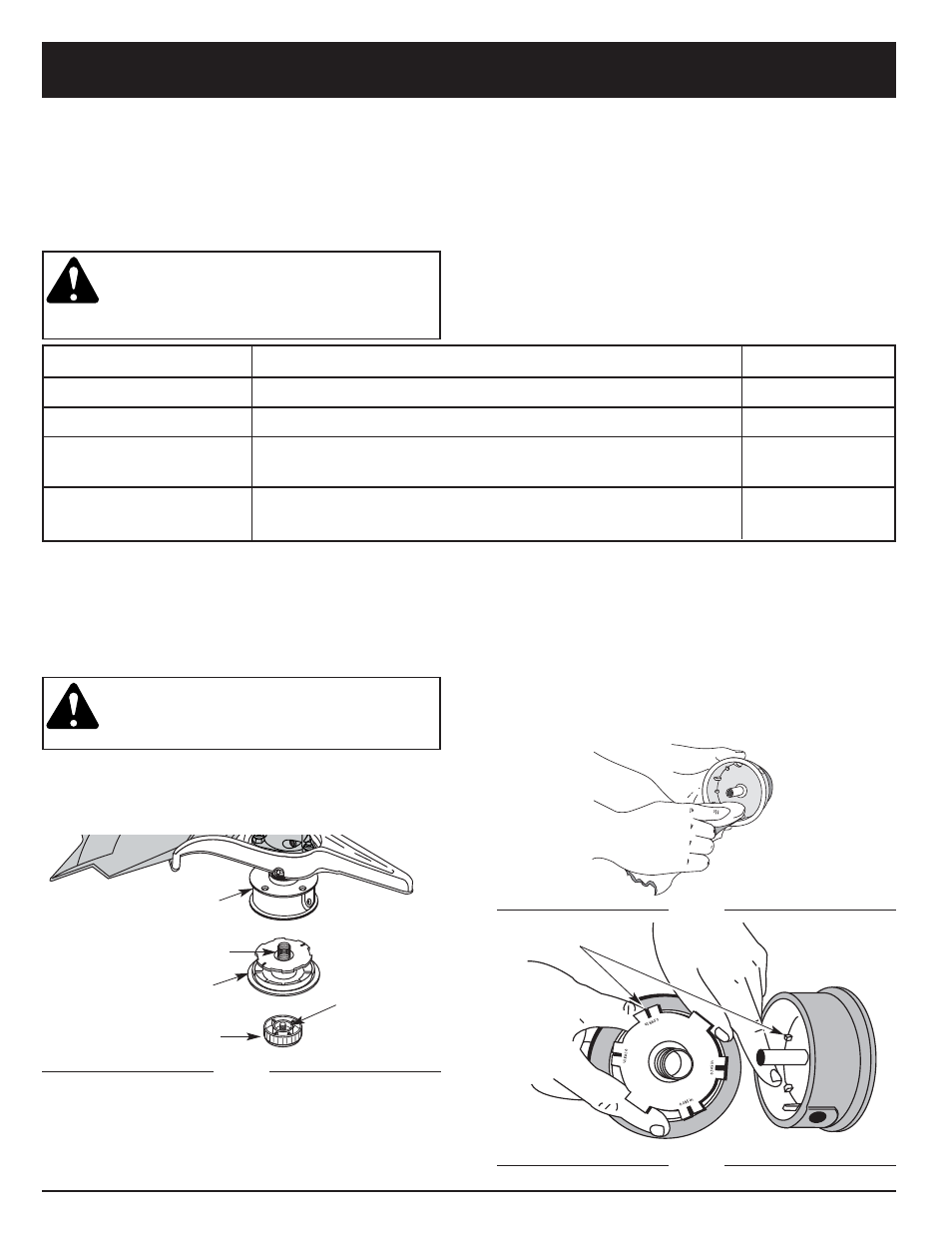

Winding the Existing Inner Reel

1. Hold the outer spool with one hand and unscrew the

Bump Knob clockwise (Fig. 27). Inspect the bolt

inside the bump knob to make sure it moves freely.

Replace the bump knob if damaged.

2. Remove the inner reel from the outer spool (Fig. 27).

3. Remove spring from the inner reel (Fig. 27).

4. Use a clean cloth to clean the the inner reel, spring,

shaft, and inner surface of the outer spool (Fig. 28).

Inner Reel

Spring

Outer Spool

Bump Knob

Bolt

Fig. 27

LINE INSTALLATION

This section covers both SplitLine™ and standard single

line installation.

Always use geniune Troy-Bilt™ 0.105 in. (2.667 mm)

replacement line. Line other than specified may make the

engine overheat or fail.

WARNING: Never use metal-reinforced line,

wire, chain, or rope, etc. These can break off

and become dangerous projectiles.

There are two methods to replace the trimming line.

• Wind the inner reel with new line

• Install a prewound inner reel

Indexing Teeth

Fig. 28

Fig. 29

FREQUENCY

MAINTENANCE REQUIRED

REFER TO:

Before Starting Engine

Fill fuel tank with correct oil and fuel mixture.

Page 12

Every 10 Hours

Clean and re-oil air filter.

Page 19

Every 25 Hours

Check spark arrestor and clean.

Page 20

Check spark plug condition and gap.

Page 22

Every 50 Hours

Inspect exhaust port and spark arrestor screen for clogging

Page 20

or obstruction to assure maximum performance levels.

NOTE: Maintenance, Replacement, or Repair of the

emission control devices and system may be

performed by any non-road engine repair

establishment, individual or authorized service

dealer.

In order to assure peak performance of your engine,

inspection of the engine exhaust port may be necessary

after 50 hours of operation. If you notice lost RPM, poor

performance or general lack of acceleration, this service

may be required. If you feel your engine is need of this

inspection, refer service to an authorized servicing

dealer, or establishment for repair. DO NOT attempt to

perform this process yourself as engine damage may

result from contaminants envolved in the cleaning

process for the port.