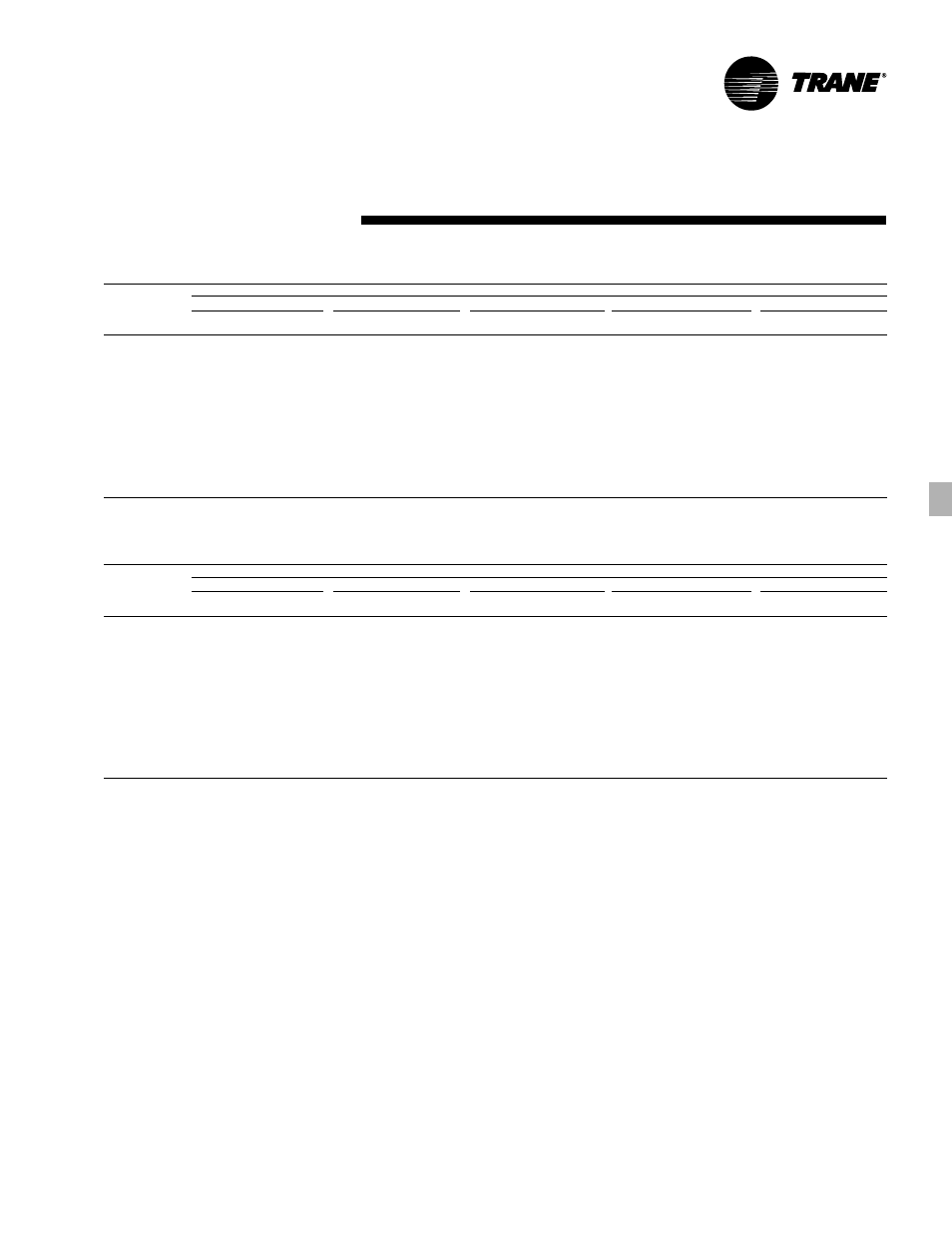

Performance data — 60 hz (10–15ton) full load, Performance data – Trane CG-PRC007-EN User Manual

Page 21

21

CG-PRC007-EN

Performance

Data — 60 HZ

(10–15 Ton)

Full Load

Entering Condenser Air Temperature (Degree F)

75.0

85.0

95.0

105.0

115.0

LWT

Percent Capacity System

Capacity System

Capacity

System

Capacity

System

Capacity System

(Deg F)

Glycol

(Tons)

KW

EER

(Tons)

KW

EER

(Tons)

KW

EER

(Tons)

KW

EER

(Tons)

KW

EER

20

28

6.0

7.6

9.4

5.6

8.5

8.0

5.4

9.4

6.9

5.1

10.4

5.9

4.9

11.5

5.1

25

24

6.6

7.8

10.2

6.3

8.6

8.7

6.0

9.6

7.5

5.7

10.6

6.4

5.4

11.8

5.5

30

19

7.3

8.0

11.0

6.9

8.8

9.4

6.6

9.8

8.1

6.3

10.8

7.0

6.0

12.0

6.0

35

14

8.0

8.2

11.8

7.7

9.0

10.2

7.3

10.0

8.8

6.9

11.1

7.5

6.6

12.3

6.4

40

0

8.9

8.4

12.6

8.5

9.3

11.0

8.1

10.3

9.5

7.7

11.4

8.1

7.3

12.6

6.9

42

0

9.2

8.5

13.0

8.8

9.4

11.3

8.4

10.4

9.7

8.0

11.5

8.3

7.5

12.7

7.1

44

0

9.5

8.6

13.3

9.1

9.5

11.6

8.7

10.5

10.0

8.3

11.6

8.6

7.8

12.8

7.3

45

0

9.7

8.6

13.4

9.3

9.5

11.7

8.9

10.5

10.1

8.4

11.6

8.7

7.9

12.9

7.4

46

0

9.8

8.7

13.6

9.4

9.6

11.8

9.0

10.6

10.3

8.6

11.7

8.8

8.1

12.9

7.5

48

0

10.2

8.8

13.9

9.8

9.7

12.1

9.3

10.7

10.5

8.9

11.8

9.0

8.4

13.0

7.7

50

0

10.5

8.9

14.2

10.1

9.8

12.4

9.7

10.8

10.8

9.2

11.9

9.3

8.7

13.2

7.9

55

0

11.4

9.1

15.0

11.0

10.0

13.2

10.5

11.0

11.4

10.0

12.2

9.8

9.4

13.5

8.4

60

0

12.4

9.4

15.8

11.9

10.3

13.9

11.4

11.3

12.1

10.8

12.5

10.4

10.2

13.8

8.9

Table PD-2 — 15 Ton — CGA 180

Entering Condenser Air Temperature (Degree F)

75.0

85.0

95.0

105.0

115.0

LWT

Percent Capacity System

Capacity System

Capacity

System

Capacity

System

Capacity System

(Deg F)

Glycol

(Tons)

KW

EER

(Tons)

KW

EER

(Tons)

KW

EER

(Tons)

KW

EER

(Tons)

KW

EER

20

28

9.3

12.2

9.1

8.9

13.6

7.8

8.4

15.3

6.6

7.9

17.2

5.5

7.3

19.3

4.5

25

24

10.3

12.5

9.9

9.8

13.9

8.5

9.3

15.6

7.2

8.7

17.5

6.0

8.1

19.7

5.0

30

19

11.4

12.7

10.7

10.9

14.2

9.2

10.3

15.9

7.8

9.7

17.8

6.5

9.0

20.0

5.4

35

14

12.6

13.0

11.6

12.0

14.5

9.9

11.4

16.2

8.4

10.7

18.2

7.1

10.0

20.4

5.9

40

0

13.9

13.3

12.5

13.3

14.9

10.7

12.6

16.6

9.1

11.9

18.6

7.7

11.1

20.9

6.4

42

0

14.4

13.5

12.9

13.8

15.0

11.0

13.1

16.8

9.4

12.3

18.8

7.9

11.6

21.1

6.6

44

0

15.0

13.6

13.2

14.3

15.1

11.3

13.6

16.9

9.6

12.8

19.0

8.1

12.0

21.3

6.8

45

0

15.2

13.7

13.4

14.5

15.2

11.5

13.8

17.0

9.7

13.0

19.0

8.2

12.2

21.3

6.9

46

0

15.5

13.7

13.5

14.8

15.3

11.6

14.1

17.1

9.9

13.3

19.1

8.3

12.5

21.4

7.0

48

0

16.0

13.9

13.9

15.3

15.4

11.9

14.6

17.2

10.1

13.8

19.3

8.6

12.9

21.6

7.2

50

0

16.6

14.0

14.2

15.9

15.6

12.2

15.1

17.4

10.4

14.3

19.5

8.8

13.4

21.8

7.4

55

0

18.0

14.4

15.1

17.2

16.0

12.9

16.4

17.8

11.0

15.5

19.9

9.3

14.6

22.3

7.9

60

0

19.5

14.8

15.9

18.7

16.4

13.7

17.8

18.3

11.7

16.9

20.4

9.9

15.9

22.8

8.4

Notes:

1

Based on the ethylene glycol concentration shown, a 10° delta T, a fouling factor of 0.0001 and sea level pressure.

2

Performance must be corrected for glycol concentrations other than those showing, delta T other than 10°, fouling factor and altitude.

3

Ethylene glycol is to be added and appropriate performance corrections are to be made for all leaving solution temperatures less than 40°F.

4. Use the following equation to calculate COP values at other than ARI conditions, COP = EER x .2928.

5. Single Phase CGA120B1 model should be re-rated at all operating points using the following factors: 1.08 x KW , 0.92 x EER

Table PD-1 — 10 Ton — CGA 120

5