General information, Hydraulic hoses, Hydraulic fitting installation – Toro Sand Pro 5020 User Manual

Page 53: Warning

General Information

Hydraulic Hoses

Hydraulic hoses are subject to extreme conditions such

as pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage condi-

tions, or mishandling during operation or maintenance.

These conditions can cause damage or premature dete-

rioration. Some hoses are more susceptible to these

conditions than others. Inspect the hoses frequently for

signs of deterioration or damage.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint on the hose.

Use two wrenches; hold the hose straight with one and

tighten the hose swivel nut onto the fitting with the other.

Before disconnecting or performing any work

system. Stop engine; lower or support box

and/or other attachment(s).

pressure. Use paper or cardboard, not hands,

to search for leaks. Hydraulic fluid escaping

under pressure can have sufficient force to

cally removed within a few hours by a doctor

WARNING

on hydraulic system, relieve all pressure in

Keep body and hands away from pin hole leaks

or nozzles that eject hydraulic fluid under high

penetrate the skin and cause serious injury. If

fluid is injected into the skin, it must be surgi-

familiar with this type of injury. Gangrene may

result from such an injury.

Hydraulic Fitting Installation

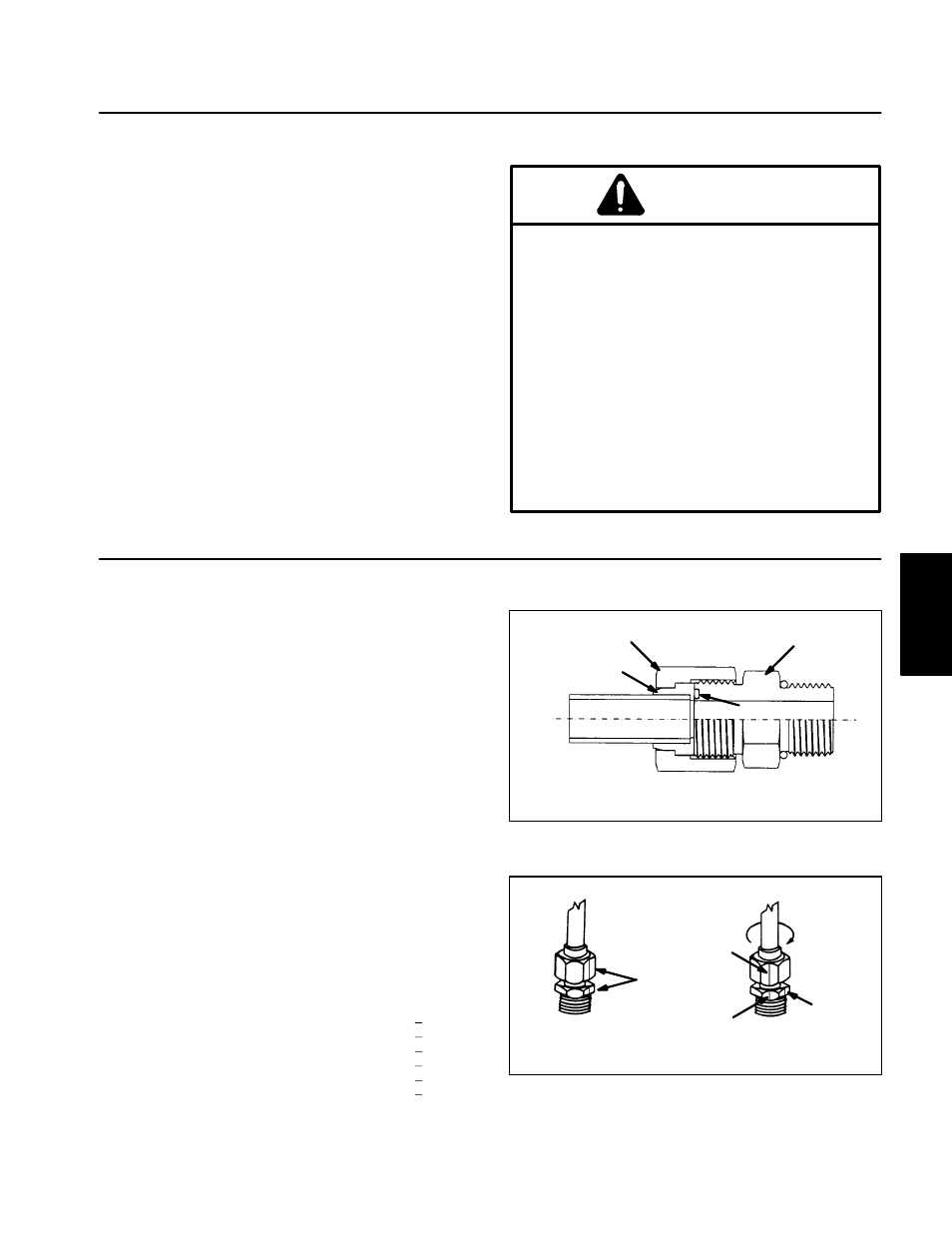

O–Ring Face Seal

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches, or any foreign material.

2. Make sure the O–ring is installed and properly

seated in the groove. It is recommended that the O–ring

be replaced any time the connection is opened.

3. Lubricate the O–ring with a light coating of oil.

4. Put the tube and nut squarely into position on the

Nut

Sleeve

Seal

Body

face seal end of the fitting and tighten the nut until finger

tight.

Figure 1

5. Mark the nut and fitting body. Hold the body with a

wrench. Use another wrench to tighten the nut to the cor-

rect flats from finger tight (F.F.F.T.). The markings on the

Final

nut and fitting body will verify that the connection has

been tightened.

Position

Mark Nut

Size

F.F.F.T.

and Body

Initial

4 (1/4 in. nominal hose or tubing)

0.75 + 0.25

Extend Line

Position

6 (3/8 in.)

0.75 + 0.25

8 (1/2 in.)

0.75 + 0.25

Finger Tight

After Proper Tightening

10 (5/8 in.)

1.00 + 0.25

12 (3/4 in.)

0.75 + 0.25

16 (1 in.)

0.75 + 0.25

Figure 2

Hydraulic Systems

Sand Pro 2020/3020/5020

Page 4 – 3

Hydraulic System (Rev. A)