The New Yorker Store Cast Iron-Oil Fired Boiler CL User Manual

Page 9

9

l. Inspect Beckett head setting on left side of

burner by insuring the blue line MD(V1) or the

line on the label MB(L1) are aligned, readjust if

necessary.

m. Tighten knurled nut.

n. Swing igniter closed, rotate tabs and tighten two

(2) igniter screws.

o. Replace burner cover and tighten burner cover

knobs.

3. On the Carlin EZ-PH Burner, use the following

procedure to complete the inspection, check the

settings and to change the nozzle to a lower firing

rate:

a. Loosen two (2) igniter latching screws, rotate

tabs and swing open igniter about hinge.

b. Loosen knurled nut and disconnect copper

connector tube.

c. Remove nozzle line electrode assembly from

burner.

d.

If high firing rate is desired, confirm the nozzle

is the proper size and type, refer to Table 9, then

proceed to Item i. below.

e. If a lower input is desired, remove the flame

retention head and then remove the nozzle that

was factory installed.

f. Locate the desired nozzle, refer to Table 9 for

proper nozzle. The nozzle must be securely

installed to assure leak free joints between the

nozzle and adapter. When installing the nozzle,

be careful not to bump or move the burner

electrodes.

g. Reinstall Flame Retention Head on Nozzle Line

Electrode Assembly. Make sure the clamp is

fully sated against the shoulder on the nozzle

adapter before securing.

h. Loosen and remove the retaining nut and factory

installed head bar from side of burner housing.

Install the proper head bar that corresponds

to the desired firing rate, refer to Table 9, and

tighten retaining nut.

i. Readjust air band to preliminary setting that

corresponds to the lower firing rate nozzle

installed, refer to Table 9.

j. Inspect and measure burner electrodes. Refer

to Figure 25A for proper electrode setting.

Readjust electrode setting to the proper

dimensions if necessary.

k. Reinstall nozzle line electrode assembly.

l. Reconnect copper connector tube.

m. Tighten knurled nut.

n. Close igniter, rotate and tighten two (2) igniter

latching screws.

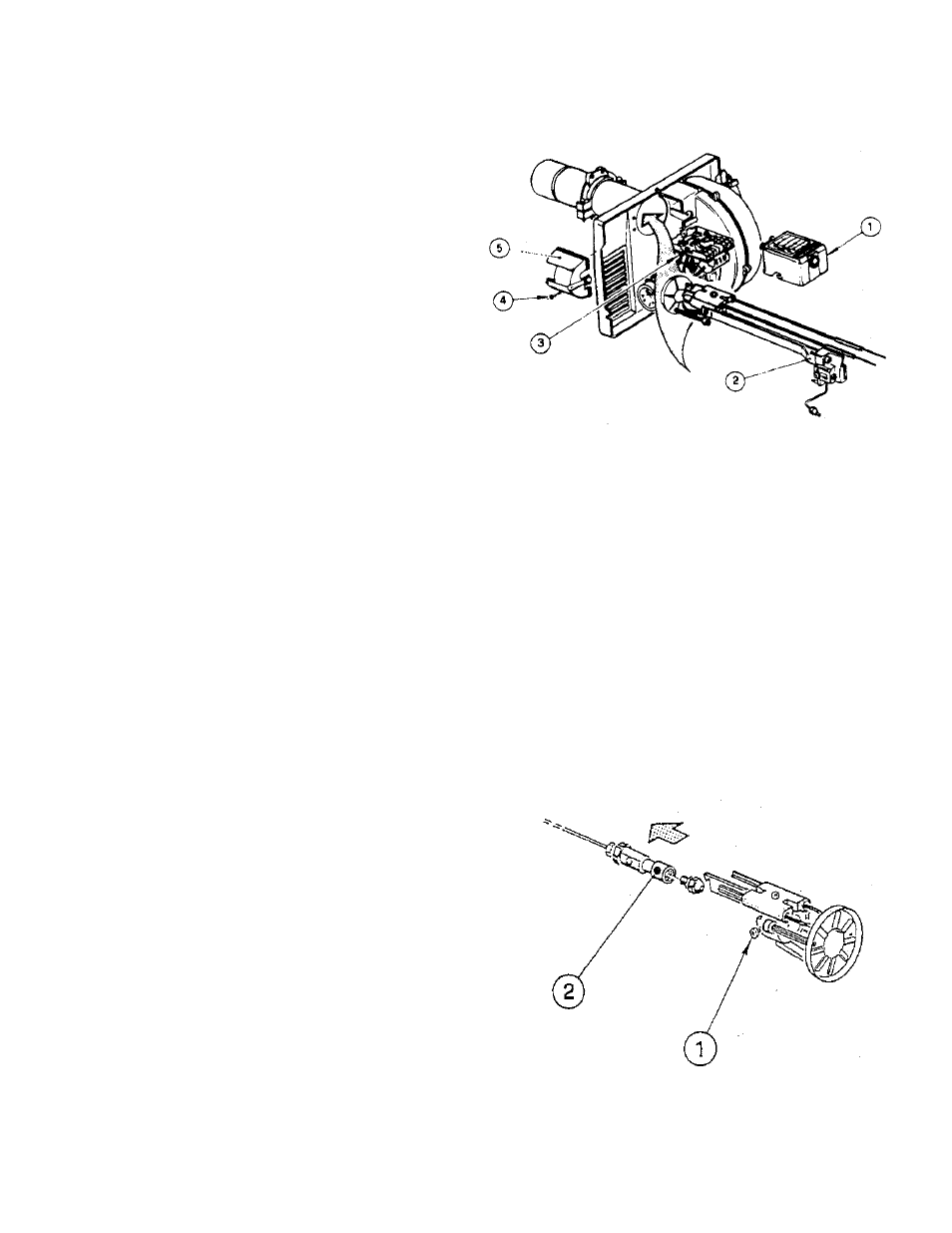

4. On the Riello 40 Series Oil Burner, use the

following procedure to complete the inspection,

check the settings and to change the nozzle to a

lower firing rate:

a. Installation/Removal of Drawer Assembly,

refer to Figure 4.

Figure : Installation/Removal of Drawer Assembly

i. Removal:

• Disconnect oil delivery tube nut from

pump.

• Loosen SCREW (3), and then unplug

PRIMARY CONTROL (1) by carefully

pulling it back and then up.

• Remove the AIR TUBE COVER

PLATE (5) by loosening the retaining

SCREW (4) (Two SCREWS-Model F5).

• Loosen SCREW (2), and then slide the

complete drawer assembly out of the

combustion head as shown.

ii. Installation:

To insert drawer assembly, reverse the

procedure in Step i above.

b. Nozzle Replacement, refer to Figure 5.

Figure 5: Nozzle Replacement

i. Remove the NOZZLE ADAPTER (2) from

the DRAWER ASSEMBLY by loosening the

SCREW (1).