Notice – The New Yorker Store Cast Iron-Oil Fired Boiler CL User Manual

Page 12

12

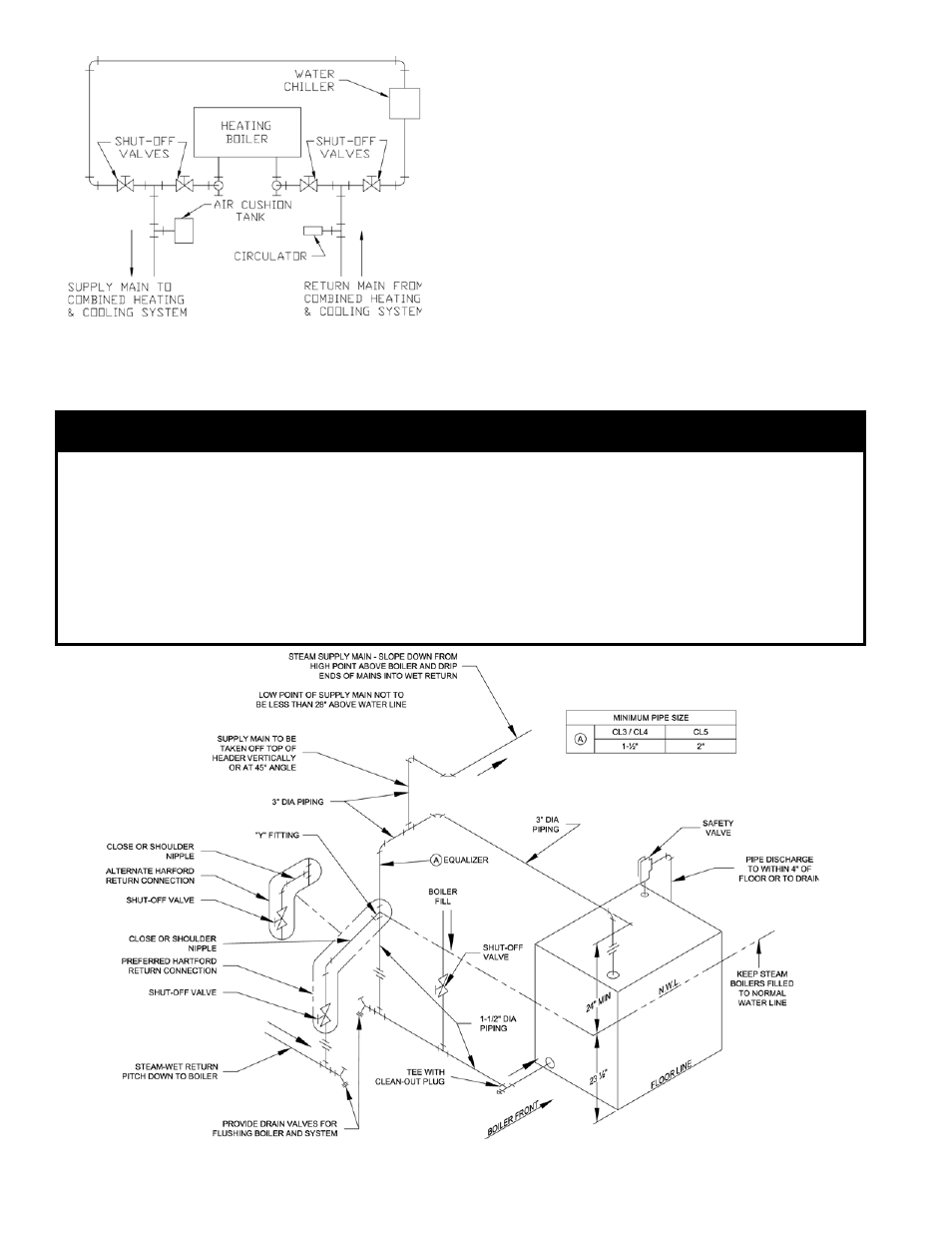

Figure 10: Recommended Piping for Combination

Heating & Cooling (Refrigeration) Systems

Figure 11: Recommended Boiler Piping For Gravity Return Steam Boiler

2. Install ¾" drain valve in wet return piping as shown

in Figure 11.

3. On boilers with rear tankless heater, factory wired

L4006A Aquastat Heater Control was not installed

in heater. Locate ¾" NPT Immersion Well, apply

sealant and thread into ¾" NPT tapping on heater.

Apply heat transfer paste (not furnished) to control

bulb and insert bulb into immersion well. Tighten

clamping screws to secure control to immersion

well. Secure 18/2 Control Cable Wire to jacket right

side panel with 5/16" cable clamp provided, refer to

Figure 1C.

4. CONNECT FIELD WIRING

a. Connect the field wiring to the pressure limit,

the R8239C Control Center, the LWCO and

the burner primary control. If equipped with

tankless heater, connect field wiring from the

aquastat control to the R8239C Control Center's

"R-G" terminals. Make the wiring connections

as shown in Figure 19B.

NOTICE

Before using copper for steam piping, consider the following characteristics of copper piping:

1) High coefficient of thermal expansion can induce mechanical stresses and cause expansion/

contraction noises if not accounted for in the piping system design and installation,

2) High heat transfer rate (heat loss) of un-insulated copper piping must be included in the normal piping

and pickup factors used to size the boiler,

) Soldering or brazing pastes and fluxes that end up in the system can cause poor heat transfer, surging,

an unsteady water line and wet steam if not thoroughly removed during boil out procedure and,

) Galvanic corrosion of the adjoining metal may occur due to dissimilar metals in certain water chemistries

if dielectric unions are not used.