Caution, Important – TOA Electronics CST38MH User Manual

Page 18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

18

If you’re installing a gas line, connect it before

the fireplace is framed and enclosed in the

finished wall. The gas knockout is determined

by a 1-1/8" (29 mm) round indentation located

at the bottom and slightly off center in the

side refractories. The KnocKouT Is always

remoVed from InsIde The fIrePlace. do

noT remoVe The KnocKouT unless you

are InsTallInG a Gas lIne. If removal is at-

tempted from the outer wrapper, side-refractory

damage may occur. With a medium-sized ham-

mer, lightly tap the surface of the indentation.

The refractory material is very thin in this area

and is easily removed. Once a small hole has

been made, continue tapping until you have

reached sufficient diameter for the gas line to

fit through. The entire knockout does not have

to be removed. Remove insulation in the gas

line channel.

Install a 1/2" (13 mm) gas supply line through

fireplace wall for connection to a decorative

gas appliance inside the firebox. Outside, the

gas supply line must connect to a gas shut-off

valve usually recessed flush into the wall or floor.

The valve should be controlled by a removable

valve key for safety.

Always plumb gas line installation per local

codes. Check all connections using a gas leak

test solution (also referred to as bubble leak

solution). Note: Using a soapy water solution

(50% dish soap, 50% water) is an effective

leak test solution but it is not recommended,

because the soap residue that is left on the

pipes/fittings can result in corrosion over time.

Never test any gas line connection with a match

or open flame.

hearth extensions and wall shields

A hearth extension must be installed with all

fireplaces. Its purpose is twofold. It protects a

combustible floor in front of the fireplace from

both radiant heat and sparks and it distinguishes

the prescribed hearth extension area from other

non-protected surfaces.

The hearth extension must extend beyond

the front and both sides of the fireplace side

openings. Use a hearth extension constructed

of a durable noncombustible material having

an equal or better (lower k value) insulating

value of k = .84 BTU IN/FT

2

HR °F or a thermal

resistance that equals or exceeds r=1.19 HR

°F FT

2

/BTU IN. A minimum 3/8" (10 mm) thick

noncombustible material is all that is required

over a noncombustible or slab floor.

If there is a continuous perpendicular side

wall closer than 18" (mm) from the fireplace

opening, it must be protected with a 40" x 40"

x 1/2" (1016 mmx 1016 mm x 13 mm) wall

shield (see Figure 46) constructed of a durable,

noncombustible material having an equal or

better (lower k value) insulating value than k =

.84 BTU IN/FT

2

HR °F. A continuous protected

side wall can not be closer than 8" (203 mm)

from the fireplace opening.

Secure the hearth extension to the floor to

prevent possible shifting.

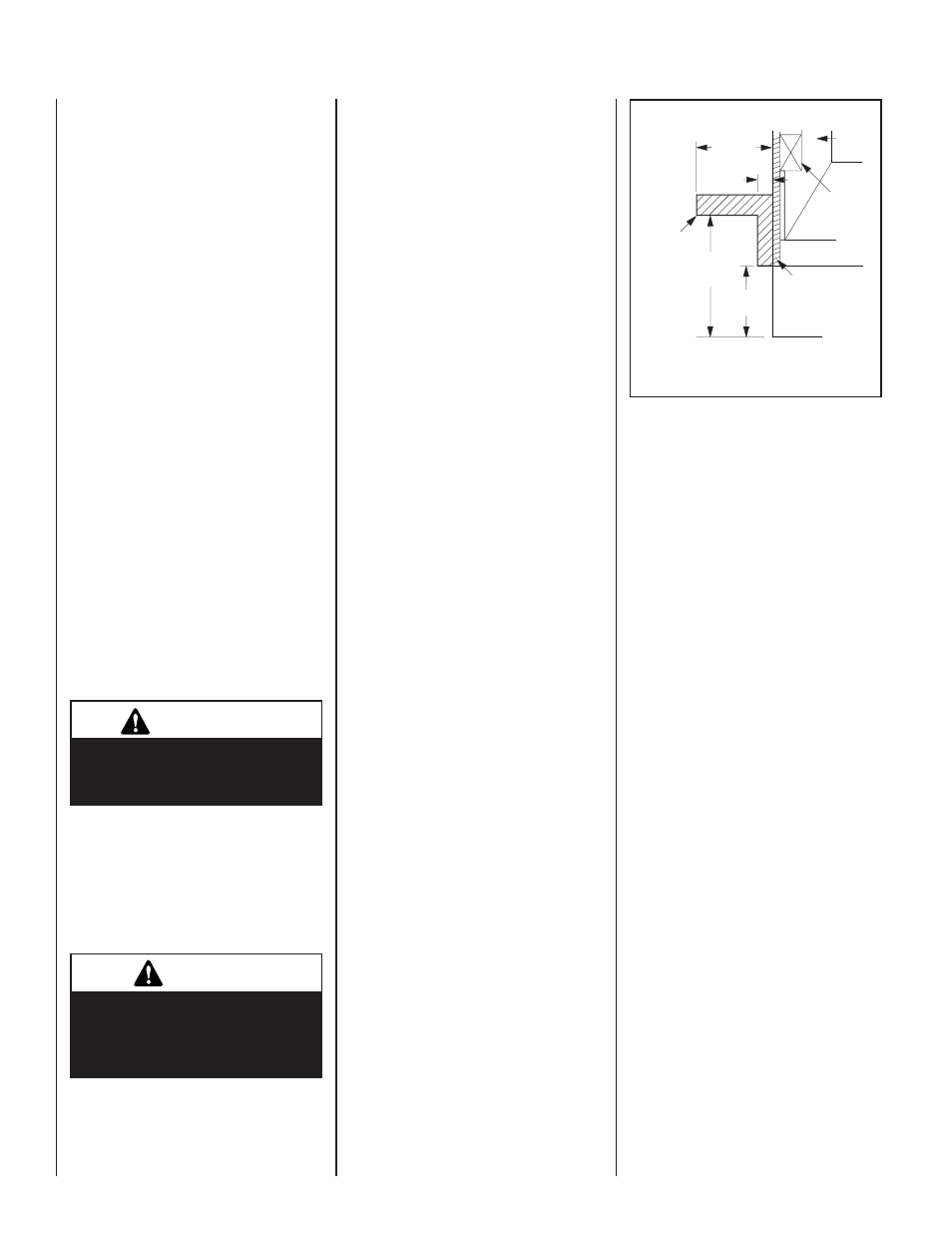

12"

(305 mm)

Min.

6"

(152 mm)

Finished Wall

Spacer

Combustible

Mantel

and Trim

12"

(305 mm)

Max.

False

Header

Typical U.S. Installation

1 ¹⁄₂"

(38 mm)

Fireplace Opening

cauTIon

when using the decorative gas

appliance, the fireplace damper

must be set in the fully open

position.

For all areas, this provision is intended only

for connection to a decorative gas appliance

incorporating an automatic shut-off device and

complying with the standard for Decorative Gas

Appliances for installation in vented fireplaces,

ANSI Z21.60. Install in accordance with the

National Fuel Gas Code, ANSI Z223.1.

ImPorTanT

repack insulation material in

square hole around gas line,

interior and exterior, to seal.

Figure 45 - Mantel Clearances

cold clImaTe InsulaTIon

If you live in a cold climate, it is especially

important to seal all cracks around the fire-

place and wherever cold air could enter the

room with noncombustible material. Surround

material must be caulked where it meets the

black metal facing of the fireplace to avoid

cold air intrusion. Use noncombustible caulk-

ing material only on fireplace facing to seal.

Also, the outside air inlet duct should be

wrapped with noncombustible insulation to

minimize the formation of condensation. Do

not place insulation materials directly against

the chimney sections.

Note: 2" (51 mm) air space must be preserved

for all materials extending for any continuous

length adjacent to the chimney.

It is especially important to insulate between

the studs of an outside chase cavity and under

the floor if the floor is above ground level. Do

not place insulation directly against the fireplace

or chimney system.

fIrePlace fInIshes

mantels and Trim

It is sometimes best to frame your fireplace af-

ter it is positioned and the chimney is installed.

Frame enclosure for chimney and fireplace with

2 x 4’s (or heavier) lumber.

Note: The header may rest on the two (2) metal

top spacers on top of the unit but the header must

not be notched to fit around the spacers.

In all installations, combustible mantels and

trim may be installed 12" (305mm) above the

opening as per NFPA 211-latest edition. and

Figure 45. If a mantel is of a noncombustible

material, it is exempt from the requirements as

long as it does not interfere with the operation

of glass doors.