Omega Engineering GP901 User Manual

Page 5

5

GP901 M-3343 05/08

Gauge Head Application Information

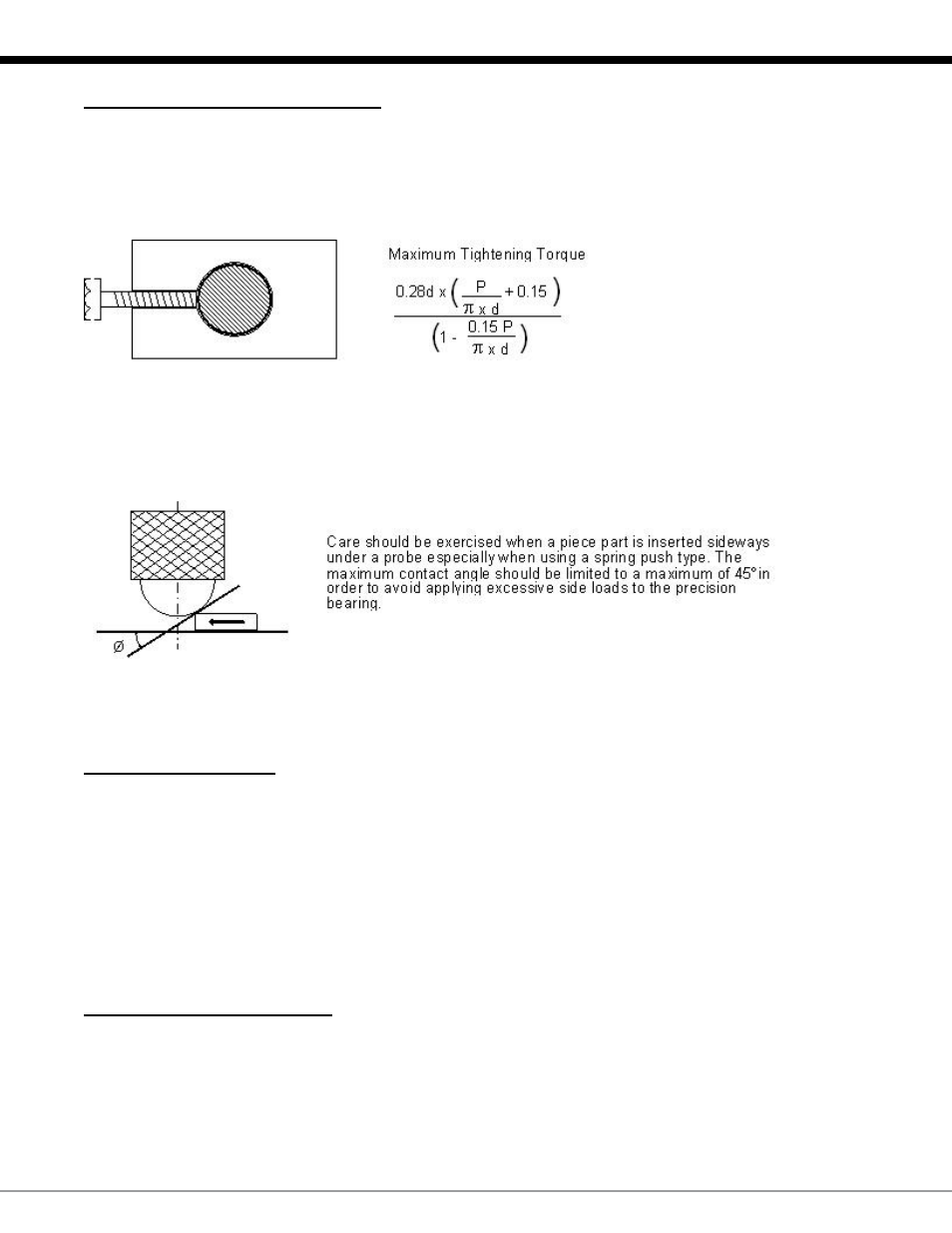

When mounting the Gauge Head in a fixture, care must be taken as the linear bearing assembly at the

tip end is made to very fine tolerances. If a high force is applied to the probe casing performance may be

affected. Ideally probes should be clamped in a yoke, split or collar clamp. If single point screw clamping

is adopted (see diagram), then a tightening torque (in Nm) should be limited to that which will give a

maximum of 50Kg point load. The Gauge Head may be mounted in any attitude.

where

d = Screw dia. (mm)

P = Screw pitch (mm)

(assumes a V form thread and 0.15 coefficient of friction).

Typical maximum torque is 0.27 Nm (i.e. M5 x 0.8 steel or 10-32 UNF steel)

A clearance hole in the fixturing of 9.5 mm F is desirable around the gaiter for satisfactory operation.

Tip

Generally, where piece parts are automatically loaded into a fixture, or where there is the possibility of

severe side loads, the use of pneumatically operated transducers is strongly recommended.

To remove the tip, the shaft should be fully retracted into the body before unscrewing.

Pneumatic Gage Heads

The tip of a pneumatic Gage Head is normally biased in the inward direction and the extension of the tip is

achieved by applying air pressure to the Gauge Head nozzle.

Air pressure may be varied within the specified limits to achieve the desired tip force at zero. The

pneumatic Gage Heads are designed to be leak free and of small volume to minimise the air flow

requirements and maintain a consistent tip force. Care must be taken not to damage the gaiter seal as the

satisfactory operation of the Gage Head is entirely dependent on this component. A clearance hole in the

fixturing of 9.5 mm F is desirable around the gaiter for satisfactory operation.

To maximise working life of the Gage Heads the air supply should be both clean and dry for continual

reliable operation. Maximum relative humidity of 60 % RH and filtered to better than 5 µm particle size.

Environmental Considerations

Most Gage Heads are designed to be used with a gaiter and are designed to withstand the rigours of

in-process gauging and will operate satisfactorily in the presence of copious amounts of coolants and

cleaning solvents.

For Gage Heads without a gaiter such as Feather touch or in situations where removal of the gaiter is

necessary (i.e. at low temperatures where stiffening of the gaiter may be a problem) then the working

atmosphere must be both clean and dry. Ingress of dirt or fluids may interfere with the performance of the

probe or even cause damage.