Additional rb 211 operating statistics, Ram assessment, Conclusion – Rolls-Royce 1004227 User Manual

Page 46: Additional rb 211 operating statistics -4, Ram assessment -4, Conclusion -4

EPRI Proprietary Licensed Material

Reliability, Availability and Maintainability

3-4

Additional RB 211 Operating Statistics

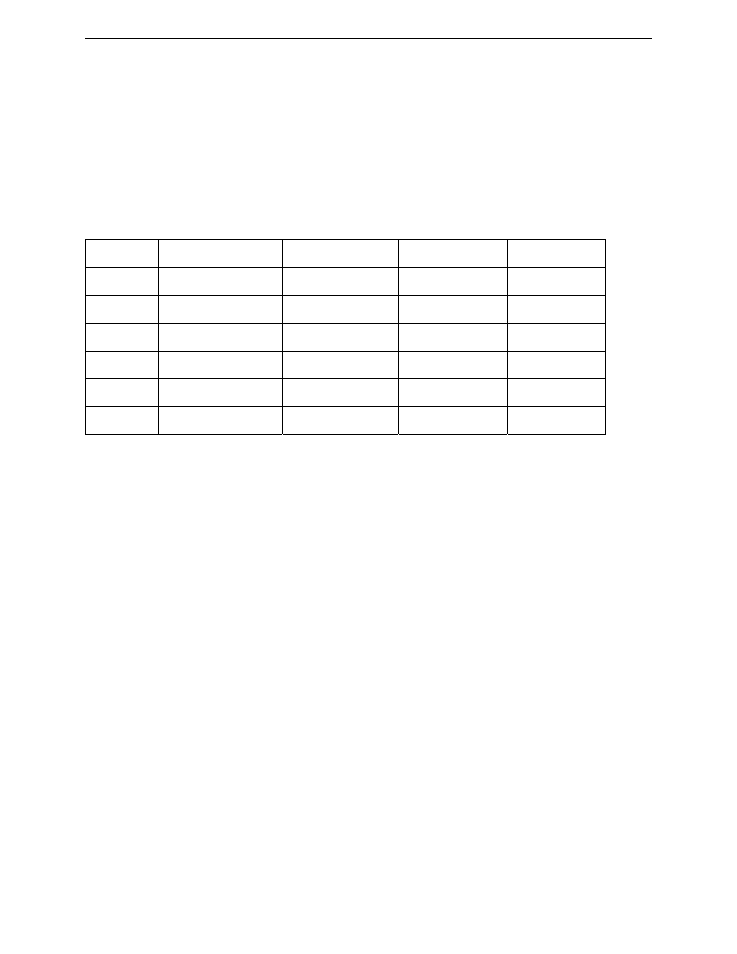

The following table provides average Reliability and Availability statistics for a limited number

of RB 211 engines based on a one-year operational study. Statistical values are from sources

other than ORAP and have not been verified.

Table 3-3

Additional RB 211 Operating Statistics

Type #

Number of Units

Service Factor Availability

% Reliability

%

24 A

9

56.4

90.2

98.3

24 C

21

61.07

90.2

98.6

24 G

13

52.26

98.0

99.5

24G DLE

16

71.8

95.9

99.8

Avg. of Fleet

93.6%

99.0%

Avg. of -24G & DLE

97.0%

99.8%

RAM Assessment

The typical benchmark for mature heavy-duty and aero-derivative engines is 99% reliability,

94% availability and 95% starting reliability, on average. The Avon exceeds these minimum

expectations; however, the RB211 and Trent machines, as represented by these particular fleets

reporting to ORAP, do not meet benchmark values. Furthermore, the Trent does not meet

expectations for starting reliability. Since the Trent engines in this sample appear to be in

peaking service, starting reliability is a critical factor as well. Again, caution is advised since the

number of units in the ORAP statistical sample is relatively small, particularly for the Avon and

RB211 engines. The single year operational study data on RB211 engines shows more favorable

availability and reliability statistics, particularly for the later sub-model type G.

Conclusion

The aero-derivatives are generally classified as “under 50 MW”. The industrial Trent breaks that

barrier and is the word’s largest aero-derivative combustion turbine at 51.2 MW. The heritage of

the aero-derivatives leads to the inherent development of flexible, high power density, and highly

efficient industrial combustion turbines. By their very nature they are generally more complex

and more exotic than the frame type (heavy duty) industrial combustion turbine. The frame type

industrial combustion turbine, however, is adopting much of the aero technology to the point that

there is a similarity of the flow paths cooling schemes, coatings, and combustion technologies.

The limiting factor is not the transfer of technology but in the manufacturing of frame size

components from the aero size components.