Wle) engine design characteristics -11 – Rolls-Royce 1004227 User Manual

Page 37

EPR Proprietary I Licensed Material

Rolls-Royce Aero-Derivative Combustion Turbine Background

2-11

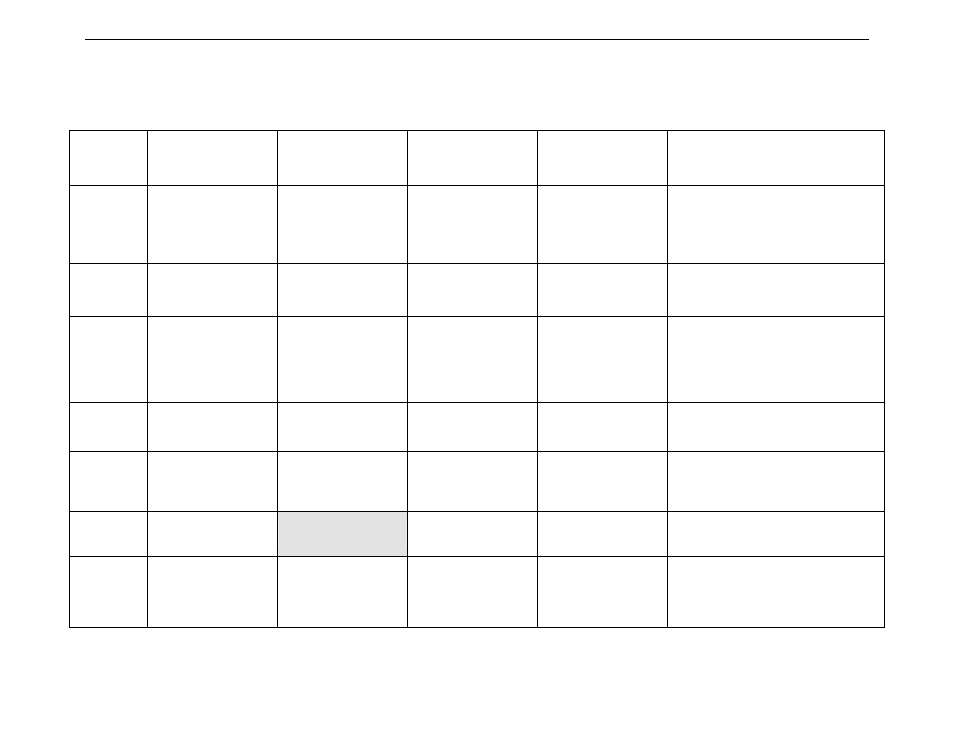

Table 2-1

Pedigree Matrix: Rolls-Royce RB211-6562, RB211-6761, Trent 60 (DLE and WLE) Engine Design Characteristics

Design

Characteristic

RB211 – 6562

(RB211-24G Gas Generator

with RT62 Power Turbine)

RB211 – 6761

(RB211-24GT Gas

Generator with RT61 Power

Turbine)

Trent 60 DLE

(Derivative of AERO 800 on

Boeing 777 and Airbus

A330)

Trent 60 WLE

(Derivative of AERO 800 on

Boeing 777 and Airbus

A330)

Reliability, Maintainability, Durability

Comments

Distinguishing

Features

Standard Annular

Combustor

(Non - DLE) 5 Modules,

Free Power Turbine,

External Gearbox

DLE Combustor Option

More efficient Power

Turbine

DLE Combustor, 3 Spools

with 6 Modules , LP

Turbine drives Generator

and LP Compressor

Directly

Std. Diffusion Combustor

with Water Injection, 3

Spools with 6 Modules ,

LP Turbine drives

Generator and LP

Compressor Directly

Fully interchangeable modules with advanced

condition monitoring techniques allows high levels

of availability with a minimum of downtime.

Year of

Introduction

1993 (DLE option in 1994)

Original RB211 Model 1980

RB211-6556 Model 1990

(-24C GG with RT56 PT)

2000

RB211-6762 Model (-24G

Gas Generator and

RT62 Free Turbine) 1999

1997

(was initially named Trent 50)

2002

Approximate

Fleet Size

240 RB211-24G

Total of 400+ RB211

incl. 260+ mech. drive and

80+ Power Generation

68 DLE engines.

All Existing Units can be

Retro-Fitted

New “short style” DLE

reduces dynamics

10+ Total Operating

1 in Ontario, Canada

5 in the UK

1 in Denmark

5 Ordered for Power

Generation

1

Four (4) development

engines running

Designed for maintenance with full modular

features and five interchangeable modules

Designed with condition monitoring system and

multiple borescope ports

Modules are light weight and easily transportable

Output, ISO, Gas

Fuel

28.8 MW (50 Hz or 60 Hz)

27.5 MW (DLE)

32.1 MW (50 Hz or 60 Hz)

51.5 MW (50 Hz)

51.7 MW (60 Hz)

(58 MW max.)

58 MW (50 Hz)

58 MW (60 Hz)

Utilized on 220 onshore applications and 120

offshore applications

Heat Rate, ISO,

LHV

9,226 Btu/kWh

(9,734 kJ/kWh)

9,415 Btu/kWh DLE

(9,933 kJ/kWh)

8,680 Btu/kWh

(9,158 kJ/kWh)

8,104 Btu/kWh

(8,488 kJ/kWh) 50 Hz

8,138 Btu/kWh

(8,530 kJ,/kWh) 60 Hz

Approx. 8,400 BTU/kWh

(8,900 kJ/kWh)

Firing

Temperature

2128

o

F

1164

o

C

2250

o

F

1232

o

C

HPT Inlet 2250

o

F

1232

o

C

HPT Inlet 2250

o

F ?

1232

o

C ?

Thermal

Efficiency, ISO,

Gas Fuel

36.2% 39.3% 42.1% 41.0%

Industry leading efficiency and reliability are

achieved by incorporating the latest technological

advances proven in the flight engine.

Efficiency and flexibility makes this design also

well-suited for pipeline operation