Installation guidelines – Raypak RP-995 User Manual

Page 5

5

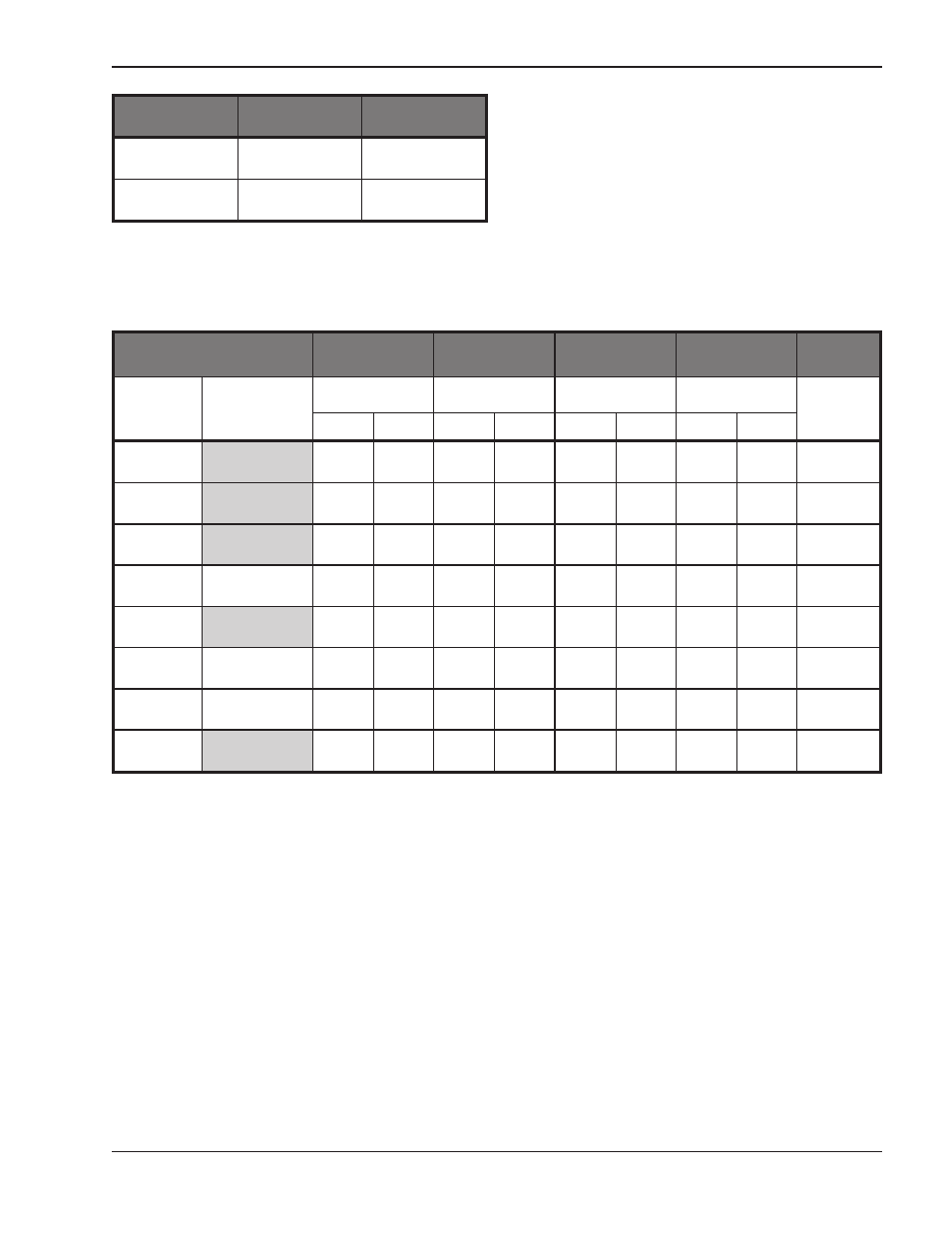

Table 3: Design Ratings

Pressure

Temperature

Tubeside

235 PSI

406°F

Shellside

190 PSI

406°F

Model

Boiler

Flow

Boiler

Head Loss

Pool

Flow

Pool

Head Loss

Heating

Surface

SS316L

CR24

Super Alloy

GPM

Feet

GPM

Feet

Sq. Ft.

Min

Max

Min

Max

Min

Max

Min

Max

RP-045

5

15

0.5

1.0

20

40

1.5

6.0

2.0

RP-075

10

20

1.0

2.5

20

50

1.5

7.0

2.8

RP-125

10

20

1.0

2.5

20

50

2.0

10.0

3.3

RP-185

CR24-185

20

30

1.0

2.0

20

50

1.5

9.5

4.9

RP-245

20

30

1.0

2.5

30

60

2.5

9.0

7.3

RP-305

CR24-305

20

35

1.5

4.0

30

60

1.5

6.0

9.4

RP-495

CR24-495

25

35

3.5

6.5

40

80

3.0

12.0

17.3

RP-995

50

100

4.0

13.0

70

120

5.5

15.0

23.7

Designed and fabricated to the

ASME B31.3 Process Piping Code

Installation Guidelines

Plumbing

Connections to the Indirect Pool Heater must be made

with materials that have similar galvanic properties to

the passivated 316 stainless steel or CR24 super alloy

of the heat exchanger. Connections to the heat source

plumbing should be made with 300 series stainless

steel nipples. Dielectric unions are recommended if

dissimilar plumbing is used. Connections to the pool

system should be made with CPVC or PVC adapters

or 300 series stainless steel nipples. Dielectric unions

are recommended if dissimilar plumbing is used.

The connection diagram, Figure 2, is shown for refer-

ence only. The system must be designed and installed

by a qualified installer and all local, state, provincial

and national codes, laws, regulations and ordinances

must be followed.

Flow

For optimal heat transfer, counter flow should be uti-

lized, that is the supply water from the heat source

should flow in the opposite direction of the return water

from the pool/spa, as shown in the connection dia-

gram, Figure 2. Systems must be designed to provide

flow rates within the range provided in Table 4. Do not

exceed the published maximum flow rates. On the

heating side, desired flow rates can be accomplished

with the pump sizing and/or use of balancing valves.

Table 4: Flow & Pressure Drop Specifications