Venting gas connection – Rinnai FS35ETRSN/US User Manual

Page 14

14

• RUN GAS SUPPLY

For pipe sizing, refer to your local gas

installation codes.

• PURGE SUPPLY OF AIR AND

DEBRIS

All foreign materials such as filings must

be purged from the gas supply, as they may

cause the gas valve to malfunction.

A means to measure the gas pressure

immediately upstream of the supply

connection to the appliance shall be

provided by the installer.

Connect and tighten union.

Use only an approved B vent system

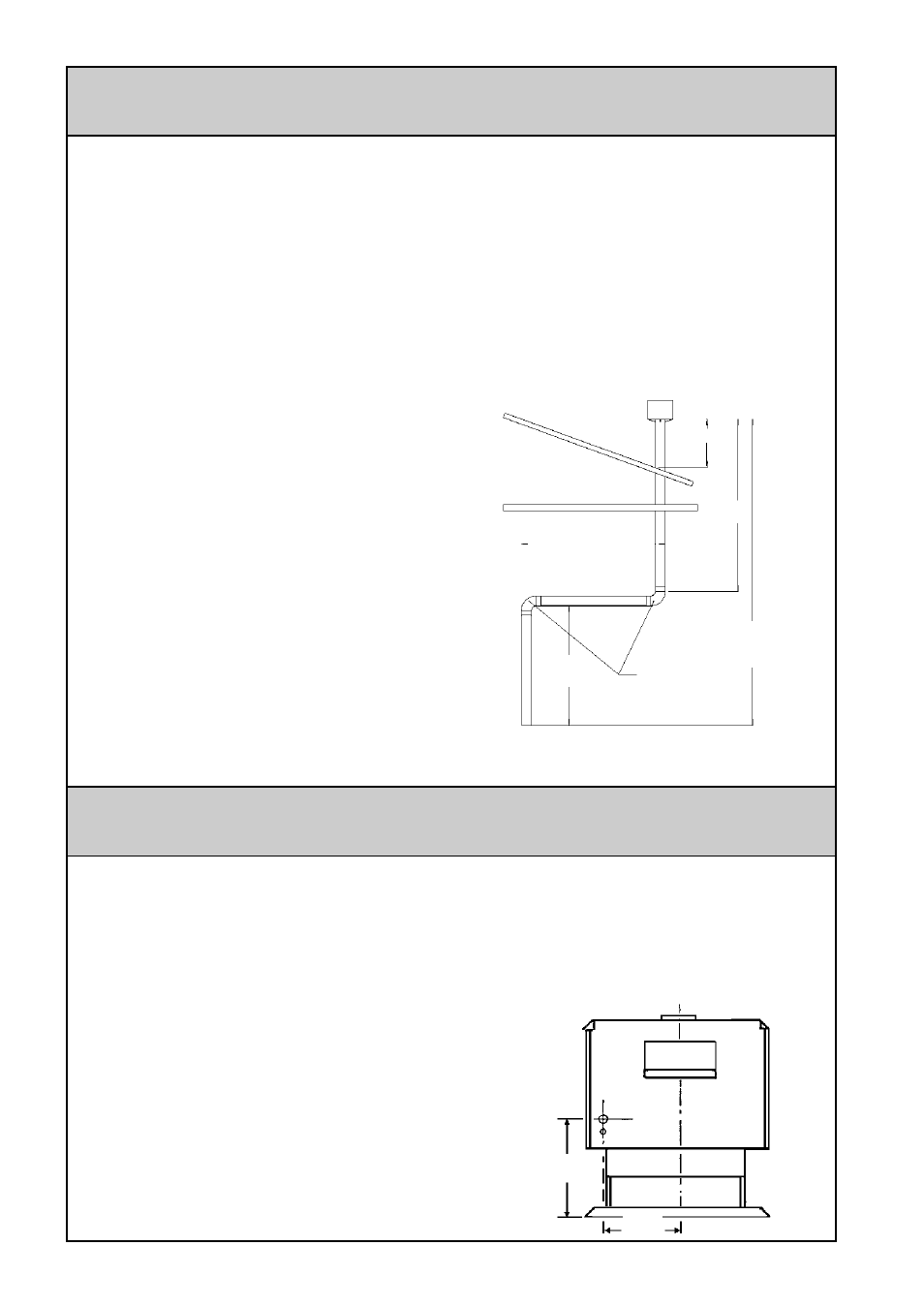

• Position the heater.

• Suspend a plumbline from the ceiling to

the centre of the flue socket.

• Mark the centre of the flue in the ceiling.

• Make a small hole in the ceiling and

double check that the flue system will be

at least 1” clear of combustible

materials.

• Cut the hole for the flue.

• Fit the ceiling plate, flue and decorative

cover.

The decorative cover must be able to slide

up to give access to the flue collar. The

inner flue must be supported independently

of the heater but allowing sufficient

movement to allow connections to and

disconnections from the flue collar.

It is recommended that the flue be

installed vertically only. If installation

prevents this then there must be at

least 4 feet of vertical flue before any

bends. The flue must not fall below

VENTING

GAS CONNECTION

On completion of work, check for gas

leaks.

Use a soapy solution all gas connections.

Leaks will be visible when the soapy

solution forms bubbles. When finished wipe

soapy solution with rag to remove residue.

Gas inlet

3/8” FNPT

10

5

/

8

”

10.6”

horizontal at any stage. There must not

be more than 2 bends in any system.

Any horizontal section of flue must be

less than 1/3 the length of vertical flue

which follows it.

See below diagram

An approved B vent system must be

attached by mechanical means to the flue

spigot and sealed using an approved high

temperature sealant.

**

X/3 maximum

maximum

2 bends

10 ft

Minimum **

4 ft

minimum

X

** Refer to local codes for other minimum

requirements.