Raypak VERSA 155C User Manual

Page 24

24

HEAT EXCHANGER REMOVAL

1. Shut water, gas and electricity off, close valves

and relieve pressure, remove relief valve. Re-

move side inspection panels.

2. Remove top holding screws.

3. Remove draft diverter, lift and remove top and flue

collector on stack-type models. Remove inspec-

tion panels.

4. Loosen bolts and disconnect flange nuts on inlet/

outlet header, loosen union(s) at gas pipe and slide

boiler away from piping until studs clear the

header.

5. Remove combustion chamber clips at the four

corners of the heat exchanger.

6. Lift heat exchanger straight up using caution not to

damage refractory.

7. Reverse above procedure to reinstall.

CONTROL IMMERSION WELL REPLACEMENT

1. Shut water off to heater and drain heat exchanger.

2. Remove jacket top panel.

3. Remove old control well with bushing and sleeve,

with 7/8" wrench or socket.

4. Slip "O" ring gasket over control well and install in

header.

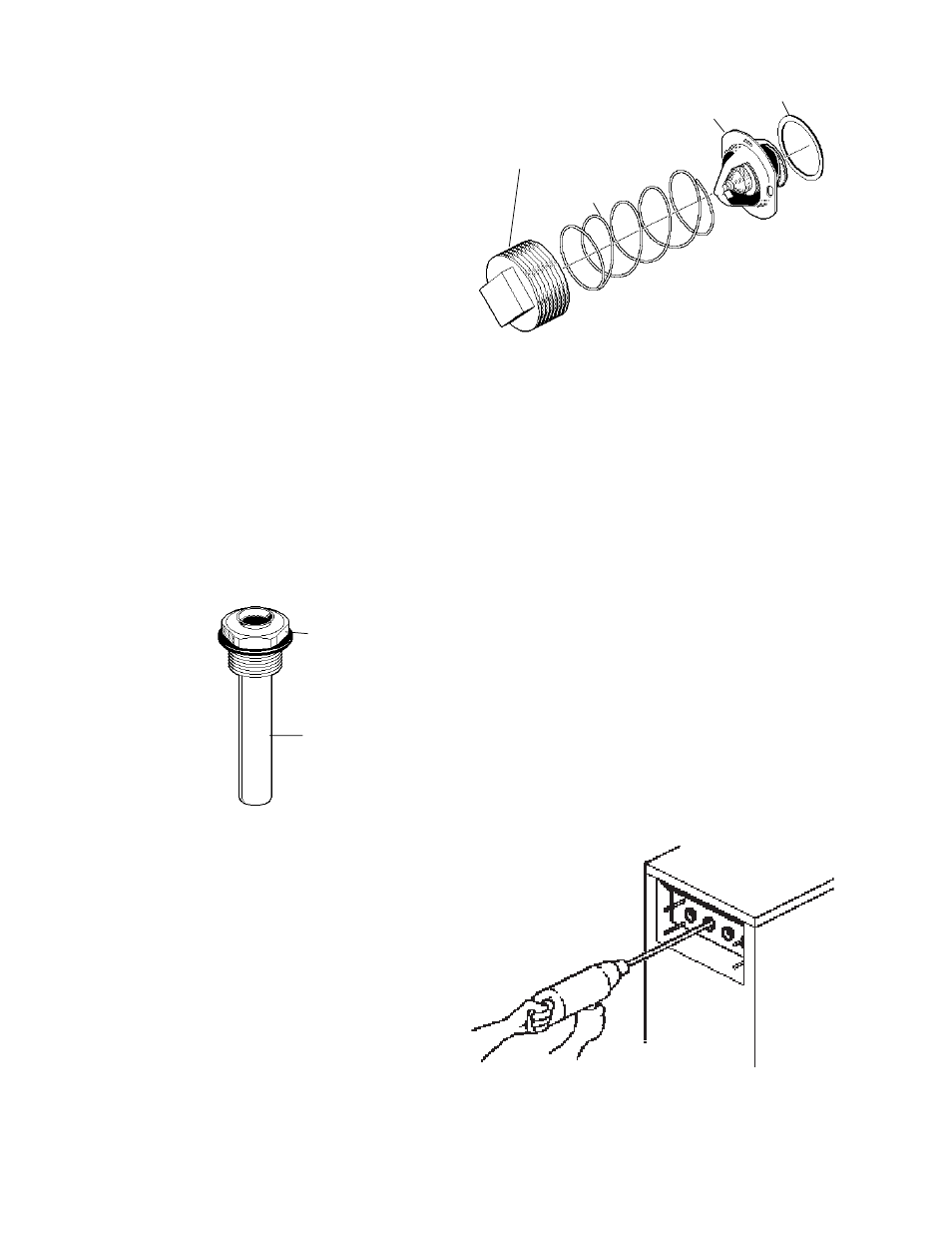

"O" RING GASKET

WELL ASSEMBLY

Fig. # 8101.0

UNITHERM GOVERNOR (U.G.) REPLACEMENT

1. Shut water, gas and electricity off, close valves and

relieve pressure.

2. Drain heat exchanger.

3. Remove retainer plug located under outlet pipe

connection.

4. Remove spring and replace old U.G. with a new

U.G.

5. Reverse above procedure to re-install.

Fig. # 8128.0

GASKET

U.G.

RETAINER PLUG

SPRING

FIig. # 8071.0

To test the operation of the Unitherm Governor,

place in hot water (over 110 °F) and watch for move-

ment against spring. If there is no movement, replace

unit.

TUBE CLEANING PROCEDURE (Typical)

Establish a regular inspection schedule, frequency

depending on local water condition and severity of

service. Do not let the tubes clog up solidly. Clean out

deposits over 1/16" in thickness.

The heater must be cleaned from the rear as

shown. It is preferable, however, to remove the heat

exchanger and the in/out header for better visibility

through the tubes and to be sure the ground-up lime

dust does not get into the system.

Note that you do not remove the top panel or the

heat exchanger, generally.

After reaming, mount the wire brush in place of the

auger and clean out debris remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in non-

inhibited de-scale solvent.