Operation – RIDGID R8411503 User Manual

Page 16

16

OPERATION

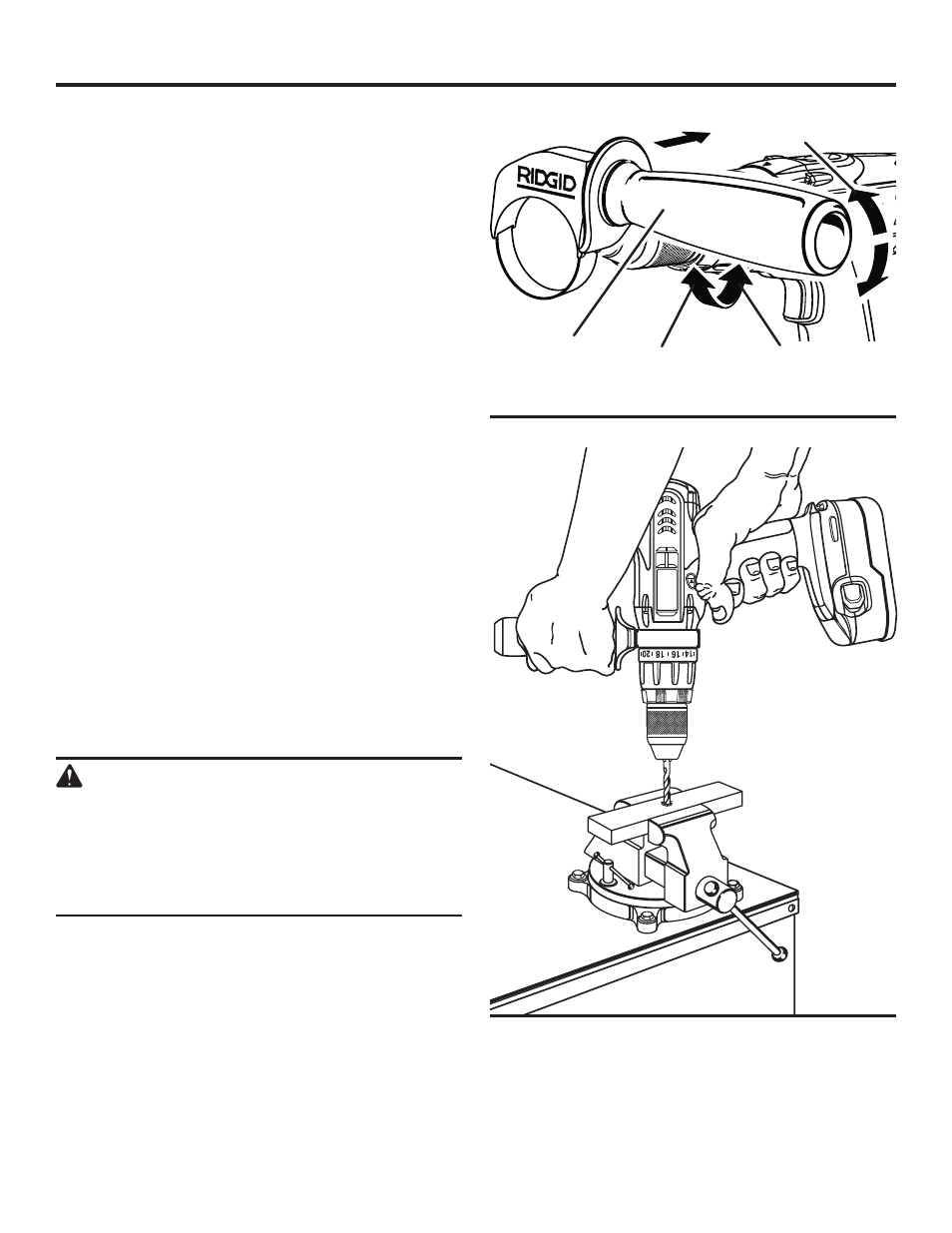

USING THE AUXILIARY HANDLE ASSEMBLY

See Figure 13

An auxiliary handle assembly is packed with the drill for

ease of operation and to help prevent loss of control. The

handle can be rotated 360°, and it can also be mounted on

the opposite side for left hand use.

To adjust the auxiliary handle assembly,

Loosen the handle assembly by turning the handle

counterclockwise.

Rotate the handle assembly to the desired operating

position.

Securely tighten by turning the handle assembly

clockwise.

Be sure the handle assembly is securely tightened against

the clamp. This secures the handle assembly.

NOTE: For convenience and ease of starting threads, the

hex nut has been trapped inside the molded slot in the

handle assembly.

DRILLING

See Figure 14.

Check the direction of rotation selector for the correct

setting (forward or reverse).�

Secure the material to be drilled in a vise or with clamps

to keep it from turning as the drill bit rotates.�

Hold the drill firmly and place the bit at the point to be

drilled.�

Depress the switch trigger to start the drill.

Move the drill bit into the workpiece, applying only enough

pressure to keep the bit cutting. Do not force the drill or

apply side pressure to elongate a hole. Let the tool do

the work.

WARNING:

Be prepared for binding at bit breakthrough. When

these situations occur, drill has a tendency to grab

and kick opposite to the direction of rotation and

could cause loss of control when breaking through

material. If not prepared, this loss of control can

result in possible serious injury.

When drilling hard, smooth surfaces, use a center punch

to mark the desired hole location. This will prevent the

drill bit from slipping off-center as the hole is started.

When drilling metals, use a light oil on the drill bit to keep

it from overheating. The oil will prolong the life of the bit

and increase the drilling action.

If the bit jams in the workpiece or if the drill stalls, stop

the tool immediately. Remove the bit from the workpiece

and determine the reason for jamming.

TO

LOOSEN

Fig. 13

Fig. 14

360°

ROTATION

TO

TIGHTEN

AUXILIARY

HANDLE

NOTE: This drill has an electric brake. When the switch

trigger is released, the chuck stops turning. When the brake

is functioning properly, sparks will be visible through the

vent slots on the housing. This is normal and is the action

of the brake.