Assembly – RIDGID 13 in. THICKNESS PLANER R4330 User Manual

Page 14

14

UNPACKING

This product requires assembly.

NOTE: Every RIDGID

®

Thickness Planer is tested at the

factory to insure its performance. You may see small amounts

of wood dust and chips on your new planer.

Carefully lift the tool from the carton and place it on a

level work surface.

NOTE: This tool is heavy. To avoid back injury, lift with

your legs, not your back, and get help when needed.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

Remove the dust hood from its position on top of the

motor housing then remove the cardboard from the

cutterhead.

NOTE: Install the dust hood before using this product.

Remove the blue plastic covering the planer table prior

to turning on this product.

The tool is factory set for accurate cutting. After

assembling it, check for accuracy. If shipping has influ-

enced the settings, refer to specific procedures explained

in this manual.

If any parts are damaged or missing, please call

1-866-539-1710 for assistance.

WARNING:

If any parts are damaged or missing, do not

operate this tool until the missing parts are

replaced.

Failure to heed this warning could result

in serious personal injury.

WARNING:

Do not attempt to modify this tool or create

accessories not recommended for use with this

tool. Any such alteration or modification is misuse

and could result in a hazardous condition leading

to possible serious personal injury.

WARNING:

Do not connect to power supply until assembly

is complete. Failure to comply could result in

accidental starting and possible serious personal

injury.

MOUNTING THE PLANER TO WORKbENCH

If your planer is to be used in a permanent location, it is

recommended you secure it to a workbench or other stable

surface. When mounting the planer to a workbench, holes

should be drilled through the supporting surface of the

workbench.

Mark holes on workbench where planer is to be mounted

using holes in planer base as a template for hole pattern.

Drill four holes through workbench.

Place planer on workbench aligning holes in the planer

base with holes drilled in the workbench.

Insert four bolts (not included) and tighten securely with

lock washers and hex nuts (not included).

NOTE: All bolts should be inserted from the top. Install

the lock washers and hex nuts from the underside of the

workbench.

Supporting surface where planer is mounted should be

examined carefully after mounting to insure that no move-

ment during use can result. If any tipping or walking is noted,

secure workbench or support surface before beginning

planing operation.

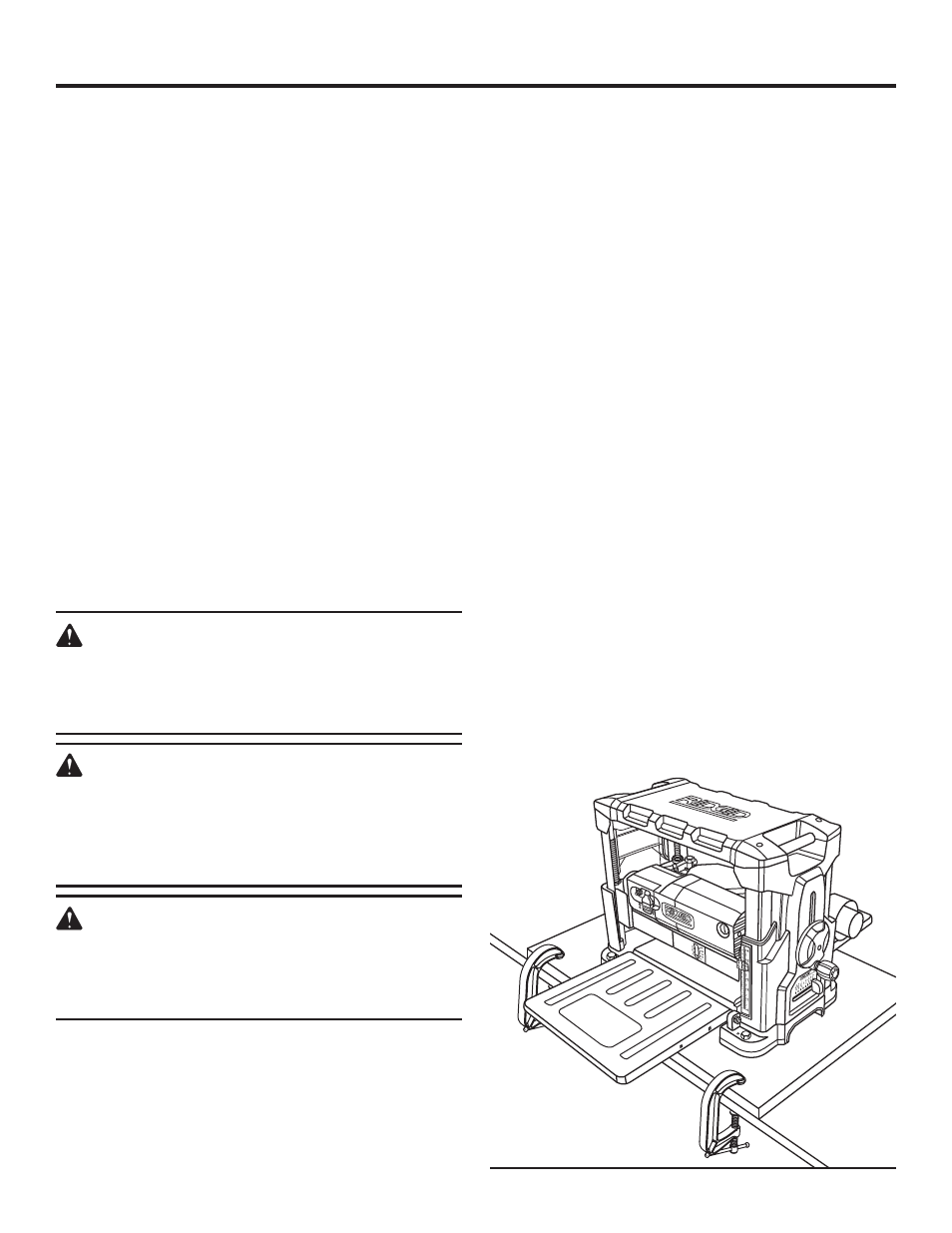

CLAMPING PLANER TO WORKbENCH

See Figure 6.

If the planer is to be used as a portable tool, it is recommended

you fasten it permanently to a mounting board that can eas-

ily be clamped to a workbench or other stable surface. The

mounting board should be of sufficient size to avoid tipping

while planer is in use. Any good grade plywood or chipboard

with a 3/4 in. thickness is recommended.

Mark holes on board where planer is to be mounted using

holes in planer base as a template for hole pattern.

Follow last three steps in section

Mounting Planer to

Workbench.

If lag bolts are used, make sure they are long enough to go

through holes in planer base and material the planer is being

mounted to. If machine bolts are used, make sure bolts are

long enough to go through holes in planer base, the material

being mounted to, and the lock washers and hex nuts.

ASSEMbLY

Fig. 6