Installation, High elevation, Gas pipe pressure testing – Regency C33-LP3 User Manual

Page 10: Gas connection, System data

10

Regency

®

CLASSIC C33-3 Freestanding Gas Stove

HIGH ELEVATION

This unit is approved in Canada for altitude 0

to 4500 ft. (CAN1 2.17-M90) with the orifi ce

supplied.

GAS PIPE

PRESSURE TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pressures

over 1/2 psig (14" w.c.).

The manifold pressure is controlled by a regulator

built into the gas control, and should be checked

at the pressure test point.

Note: To properly check gas pressure, both

inlet and manifold pressures should

be checked using the valve pressure

ports on the valve.

1) Make sure the valve is in the "OFF" posi-

tion.

2) Loosen the "IN" and/or "OUT" pressure

tap(s), turning counterclockwise with a

1/8"

wide

fl

at

screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" ID hose.

4) Light the pilot and turn the valve to "ON"

position.

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specifi ed on the safety

label.

6) When fi nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8" fl at

screwdriver. Screw should be snug, but do

not over tighten.

GAS CONNECTION

The gas connection is a 3/8" NPT rigid pipe.

The gas line can be rigid pipe or to make in-

stallation easier, use a listed fl exible connector

and/or copper pipe if allowed by local codes.

For minimum and maximum supply pressure

see the System Data table below.

Note: During any pressure testing of the

gas supply piping system that ex-

ceeds test pressures of 1/2 psig, this

appliance and its individual shut-off

valve must be disconnected from

the piping system. If test pressures

equal to or less than 1/2 psig are used

then this appliance must be isolated

from the piping system by closing

its individual manual shut-off valve

during the testing.

Output capacity:

The effi ciency rating of the appliance is a

product thermal effi ciency rating determined

under continuous operating conditions and

was determined independently of any installed

system.

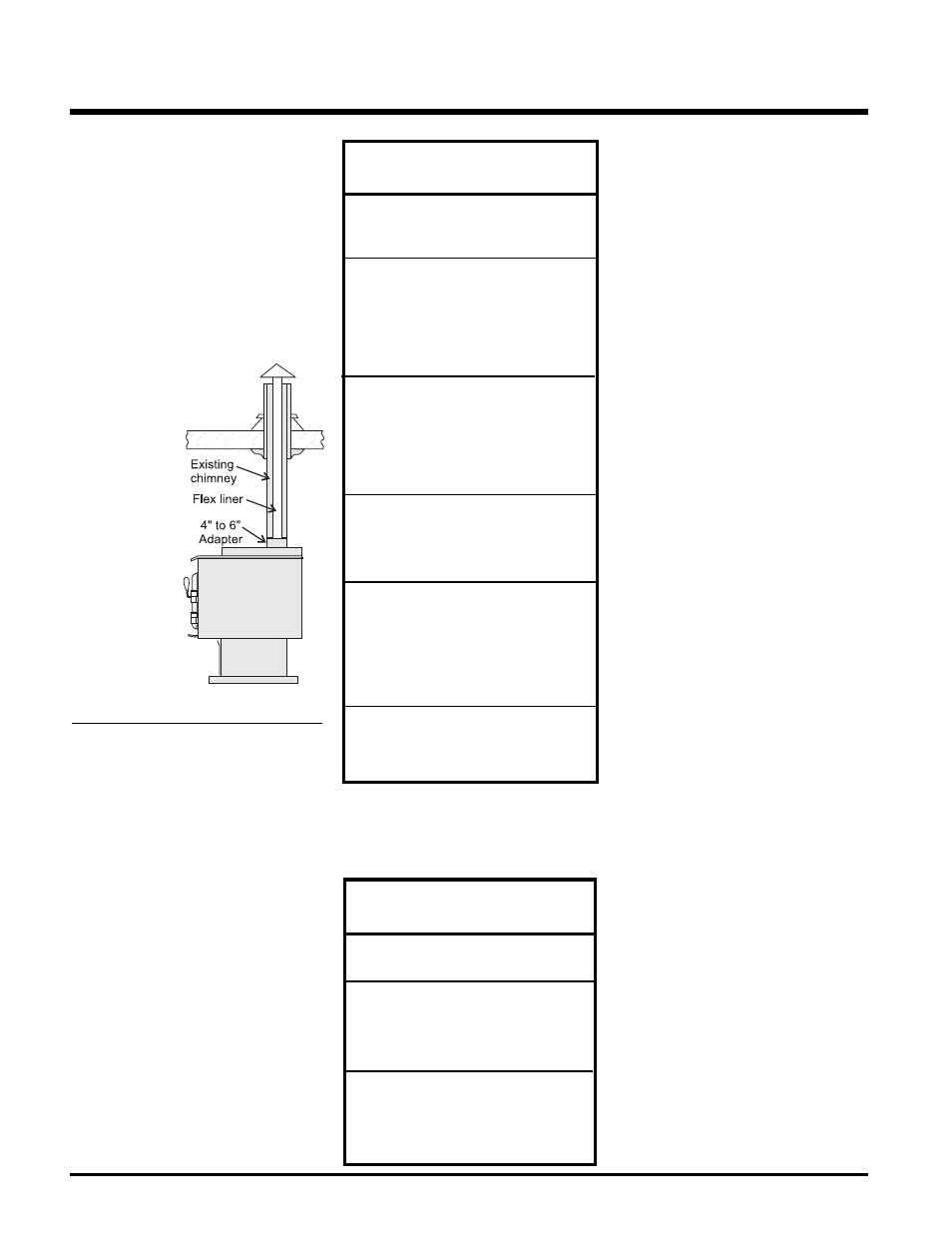

INSTALLATION

Installing into Existing

Woodstove Flue System

1) Clean existing chimney system.

2) Install stove pipe adapter

3) Install any reducers that may be needed to

fi t 6" fl ue pipe adapter.

4) Run 4" fl ex liner into existing chimney.

5) Slip liner through 6" fl ue pipe and hook up

to fl ue collar with screws.

Note: For ease of in-

stallation, use a

slip section when

installing

with a ver-

tical flue

pipe.

SYSTEM DATA

(For 0 to 2,000 feet altitude)

Orifi ce Sizes:

Burner Natural

Gas #36

Burner Propane

#52

Max. Input Rating

Natural

Gas

33,000

Btu/h

Propane

33,000

Btu/h

Min. Input Rating

Natural

Gas

17,000

Btu/h

Propane

17,000

Btu/h

Output Capacity with blower Off

Natural

Gas

23,200

Btu/h

Propane

23,100

Btu/h

Output Capacity with blower On

Natural

Gas

24,600

Btu/h

Propane

24,420

Btu/h

Supply Pressure

Natural

Gas

min. 5.0"

w.c

max. 8.0"

w.c.

Propane

min. 12.0"

w.c.

max. 13.0"

w.c.

Manifold Pressure High

Natural Gas

3.8" +/- 0.2" w.c.

Propane

11"

+/-

0.2"

w.c.

Manifold Pressure Low

Natural Gas

1.1" +/- 0.2" w.c.

Propane

2.9"

+/-

0.2"

w.c.

Electrical: 120V, 1.13A, 60 Hz.

Circulation Fan: (optional) 2 speed

75/125 CFM.

Log Set: Ceramic fi ber, 4 per set.

SYSTEM DATA

(For 2,000 to 4,500 feet altitude)

Orifi ce Sizes:

Burner Natural

Gas #38

Max. Input Rating

Natural

Gas

29,000

Btu/h

Min. Input Rating

Natural

Gas

15,300

Btu/h

Output Capacity with blower Off

Natural

Gas

20,400

Btu/h

Output Capacity with blower On

Natural

Gas

21,600

Btu/h