Maintenance – Ryobi DP102L User Manual

Page 23

22

23

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing

dust. If operation is dusty, also wear a dust mask.

WARNING:

To prevent accidental starting that could cause possible

serious personal injury, turn off the tool, remove the

switch key, and unplug the drill press before performing

any maintenance or adjustment.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-

based products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

�After using the drill press, clean it completely and lubricate

all sliding and moving parts. Apply a light coat of automotive-

type paste wax to the table and column to help keep the

surfaces clean.

LUBRICATION

n

Lower spindle to maximum depth and oil moderately once

every three months.

n

Oil the column lightly every two months.

n

If cranking becomes difficult, grease gear rack lightly.

The ball bearings in the tool are permanently lubricated.

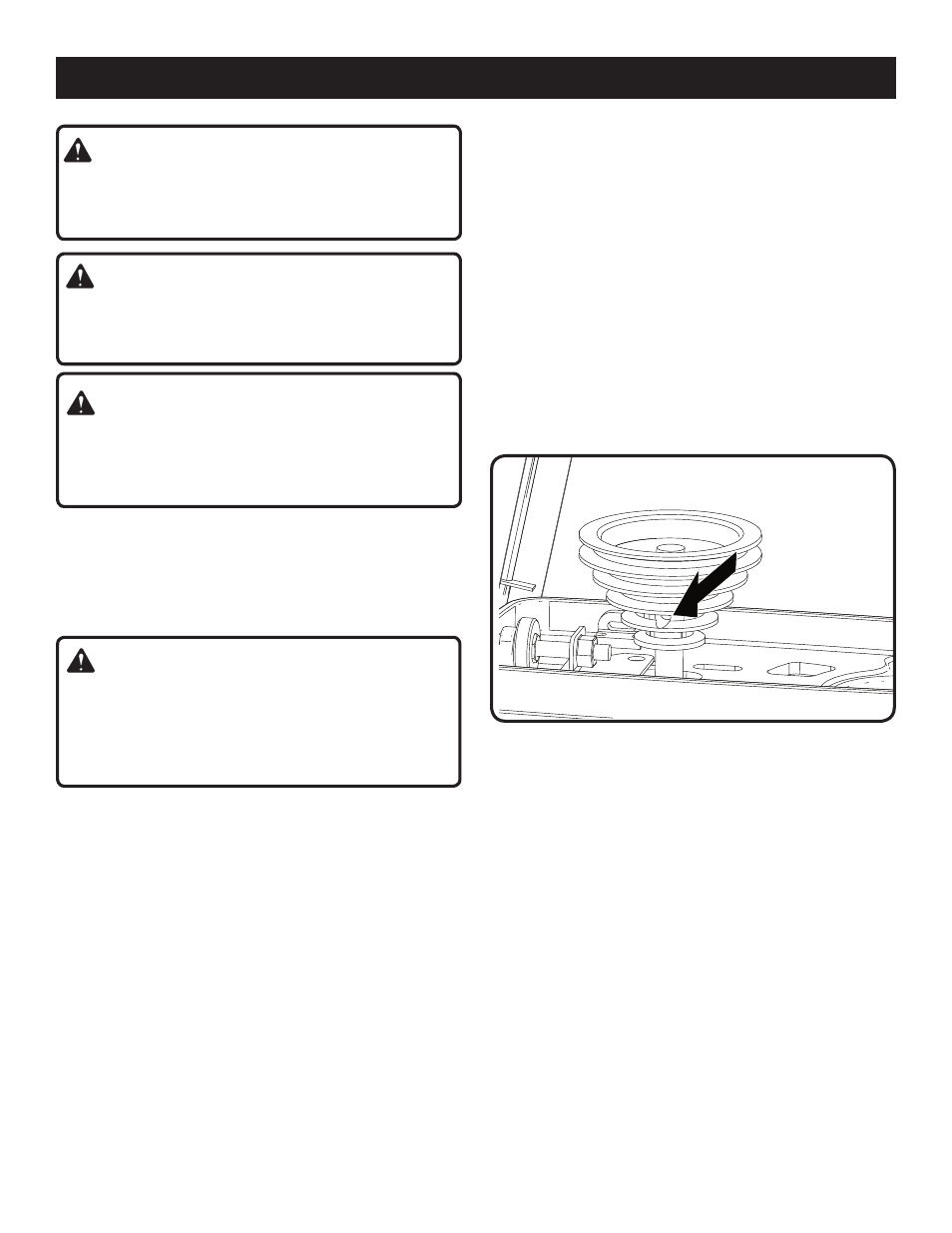

Fig. 25

PULLEY

SET SCREWS

MOTOR/ELECTRICAL

The induction motor is easy to maintain but must be kept

clean. Do not allow water, oil, or sawdust to accumulate on

or in it. The sealed bearings are permanently lubricated and

need no further attention.

HEAD ASSEMBLY AND MOTOR HOUSING

Frequently blow out any dust that may accumulate inside

the head assembly and/or motor housing.

PULLEYS

See Figure 25.

Should you feel an unusually high level of vibration, the pul-

leys may not be tightly secured on the motor and/or spindle

shafts. To make sure the pulleys are properly seated and

tight, locate the set screw on each of the pulleys. Tighten

each set screw with the hex key.

GEAR RACK

Periodically lubricate the worm gear and gear rack in order

to keep the vertical movement smooth and to help prolong

the life of the drill press.

BATTERIES

Check the laser batteries regularly to avoid deterioration.

Remove the batteries if you will not be using the laser for

an extended time.