Installation, Flue connector bracket, Leg option on h2100 hearth heater – Regency I3100L User Manual

Page 8: Installation into a factory built fireplace, Installation into a masonry fireplace

Regency Wood Insert & Hearth Heater

8

1) Positive

Flue

Connection

with

Cleanout

FLUE CONNECTOR

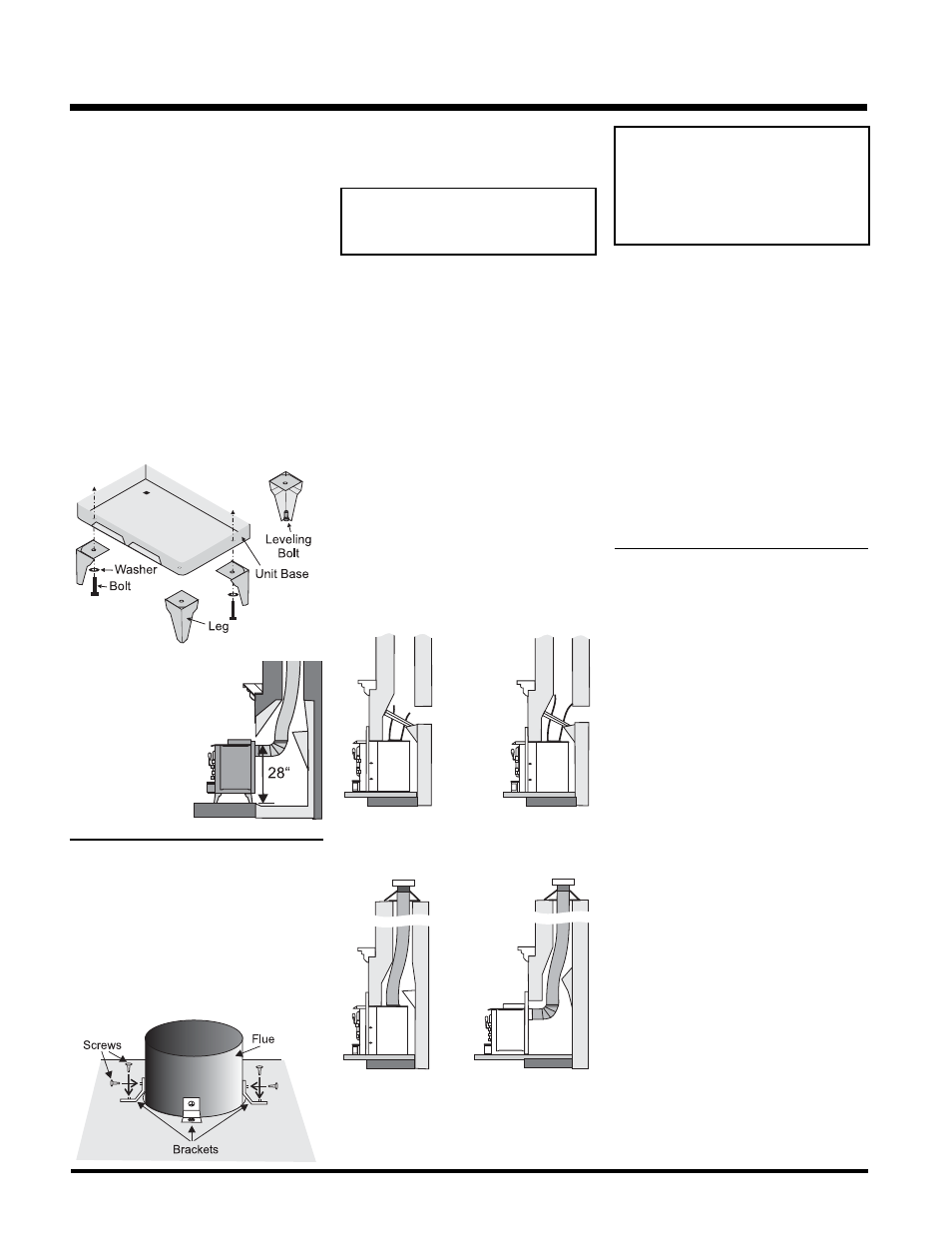

BRACKET

Package contains: 3 brackets and 6 screws.

These brackets are to be used to hold the fl ue

liner (not supplied) to the Insert and keep the

connection. The brackets are screwed into the

top of the Insert in the pre-punched holes and

then screwed into the fl ue liner.

INSTALLATION

2) Direct

Flue

Connection

with

Cleanout

3a) Full Flue Liner

(No

Cleanout

Required)

3b) Hearth Heater with

Full

Flue

Liner

(No

Cleanout

Required)

Note: A clean-out door is sometimes

required, by your inspector, to be

installed when either the Positive fl ue

connection or Direct fl ue connection

method is used.

NOTE: Adding the

legs changes the

height of the unit,

make sure you have

sufficient clearance

(min. 28") for your fl ue

connection.

LEG OPTION ON H2100

HEARTH HEATER

The addition of legs to the Hearth Heater does

not alter its certifi cation, it does not become a

freestanding woodstove. The H2100 can only

be installed as a Hearth Heater i.e. vented into

a masonry or factory built fi replace.

The instructions below apply to the steel leg,

painted cast leg and the gold plated cast leg.

It will be easier to attach the legs to the stove

if it is tipped on its back (preferably on a soft

surface to prevent scratching).

1) Thread the bolt and washer through the

leg, and then into the nutsert in the base

of the stove and tighten.

2) Level the stove by adjusting the levelling

bolts in the bottom of each leg.

The use of one of the connection methods listed

on this page not only increases the safety of your

insert by directing the hot gases up the fl ue, but

will also help increase the unit's effi ciency and

decrease creosote deposits in the chimney.

When a connected fl ue or liner is in use, the

insert is able to “breathe” better by allowing a

greater draft to be created. The greater draft can

decrease problems such as, diffi cult start-ups,

smoking out the door, and dirty glass.

INSTALLATION INTO A

FACTORY BUILT

FIREPLACE

1) When installed in a factory built fi replace, a

full stainless steel rigid or fl exible fl ue liner

is mandatory, for both safety and perform-

ance purposes. When a fl ue or liner is in

use, the insert is able to breathe better by

allowing a greater draft to be created. The

greater draft can decrease problems such

as, diffi cult start-ups, smoking out the door,

and dirty glass.

2) In order to position the fl ue liner, the exist-

ing rain cap must be removed from your

chimney system. In most cases the fl ue

damper should also be removed to allow

passage of the liner.

3) In most cases opening the existing spark

screens fully should give enough room for

the insert installation. If it does not, remove

and store.

When referencing installation or connec-

tion to masonry fi replaces or chimneys, the

masonry construction must or shall be code

complying.

INSTALLATION INTO A

MASONRY FIREPLACE

The insert must be installed as per the require-

ments of your local inspection authority. Three

methods of fl ue connection are acceptable in

most areas, these include:

1) Positive fl ue connection, where a large

blocking plate and a short connector pipe

is used.

2) Direct fl ue connection, where a smaller

blocking plate and a connector pipe to the

fi rst fl ue liner tile is used.

3) Full fl ue liner, where a stainless steel rigid

or fl exible liner pipe is routed from the insert

outlet collar to the top of the chimney.

Regency highly recommends the use of a full

liner as the safest installation and provides the

most optimum performance. Your retailer should

be able to help you decide which system would

be the best for your application.

In Canada this fi replace insert must be in-

stalled with a continuous chimney liner of 6"

diameter extending from the fi replace insert

to the top of the chimney. The chimney liner

must conform to the Class 3 requirements

of CAN/ULC-S640, Standard for Lining Sys-

tems for New Masonry Chimneys.