Operation – RIDGID R86006 User Manual

Page 12

OPERATION

HI

SPEED

TWO-SPEED GEAR

TRAIN (HI-LO)

1

2

LOW

SPEED

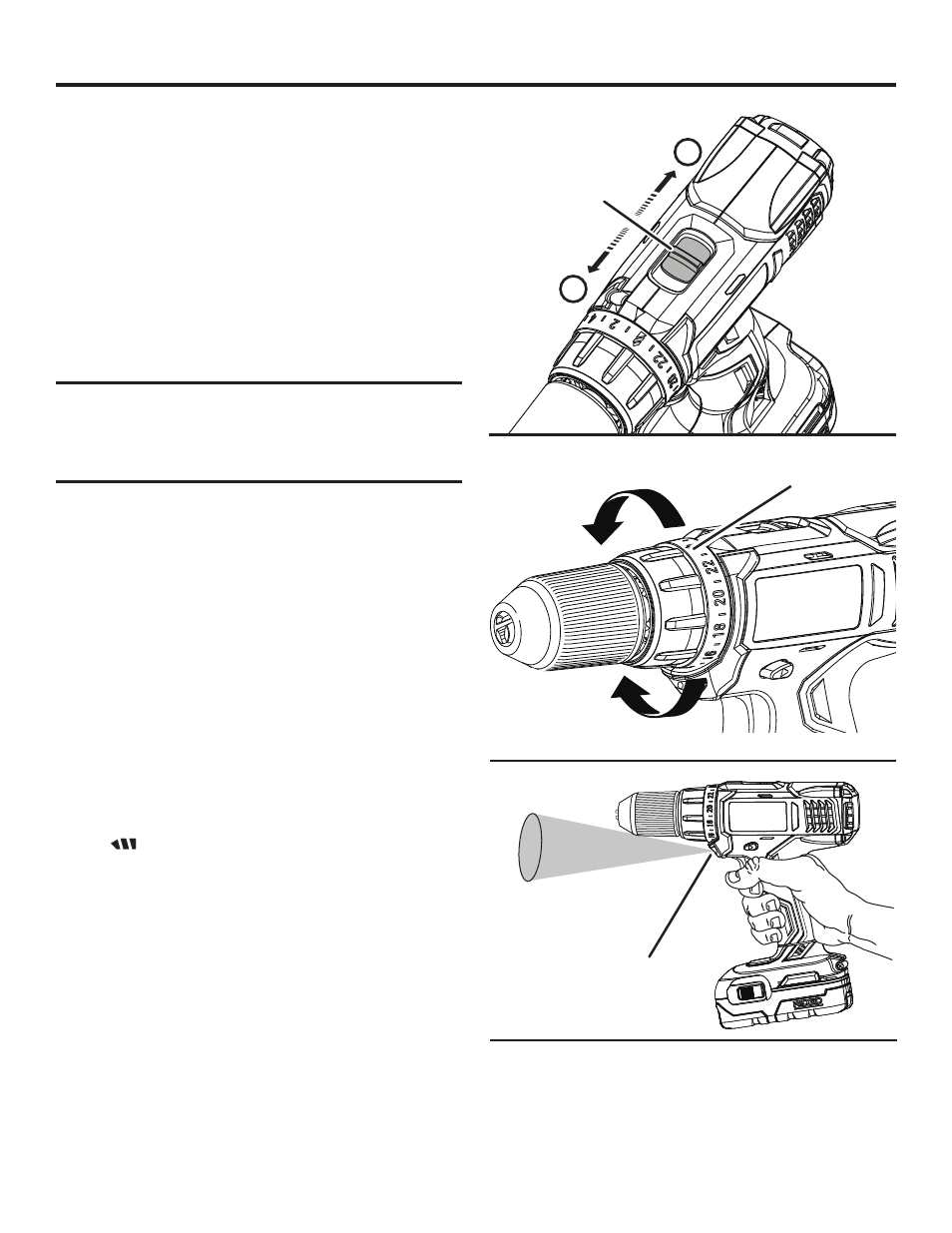

TWO-SPEED GEAR TRAIN

See Figure 5.

The drill has a two-speed gear train designed for drilling or

driving at

LO (1) or HI (2) speeds. A slide switch is located on

top of the drill to select either

LO (1) or HI (2) speed. When

using drill in the

LO (1) speed range, speed will decrease

and unit will have more power and torque. When using drill in

the

HI (2) speed range, speed will increase and unit will have

less power and torque. Use

LO (1) speed for high power

and torque applications and

HI (2) speed for fast drilling or

driving applications.

NOTE: If you have difficulty changing from one gear range to

the other, turn the chuck by hand until the gears engage.

CAUTION:

Never change gears while the tool is running.

Failure to obey this caution could result in serious

damage to the drill.

ADJUSTABLE TORQUE CLUTCH

This product is equipped with an adjustable torque clutch

for driving different types of screws into different materials.

The proper setting depends on the type of material and the

size of screw you are using.

ADJUSTING TORQUE

See Figure 6.

There are twenty-four torque indicator settings located on

the front of the drill.

Rotate the adjusting ring to the desired setting.

• - 4

For driving small screws

• 5 - 8

For driving screws into soft material

• 9 -

For driving screws into soft and hard

materials

• 3 - 6 For driving screws into hard wood

• 7 - 3 For driving large screws

•

For heavy drilling

LED WORKLIGHT

See Figure 7.

The LED worklight under the chuck of the drill will come

on when the switch trigger is depressed. This provides

additional lighting on the surface of the workpiece for

operation in lower-light areas.

Fig. 5

TORQUE

ADJUSTMENT RING

TO DECREASE

TORQUE

TO INCREASE

TORQUE

Fig. 6

LED

WORKLIGHT

Fig. 7