Norton Abrasives C6136 User Manual

Page 21

21

8. If wet cutting turn on the water supply at the source and then open the

water valves on the saw. Make sure that there is a minimum of 5 to 8

gallons per minute of water flow!! If using the water pump turn the Pump

Control Switch to the “On” position.

9. Be sure that the engine is running at full throttle!!! Check Engine Speed

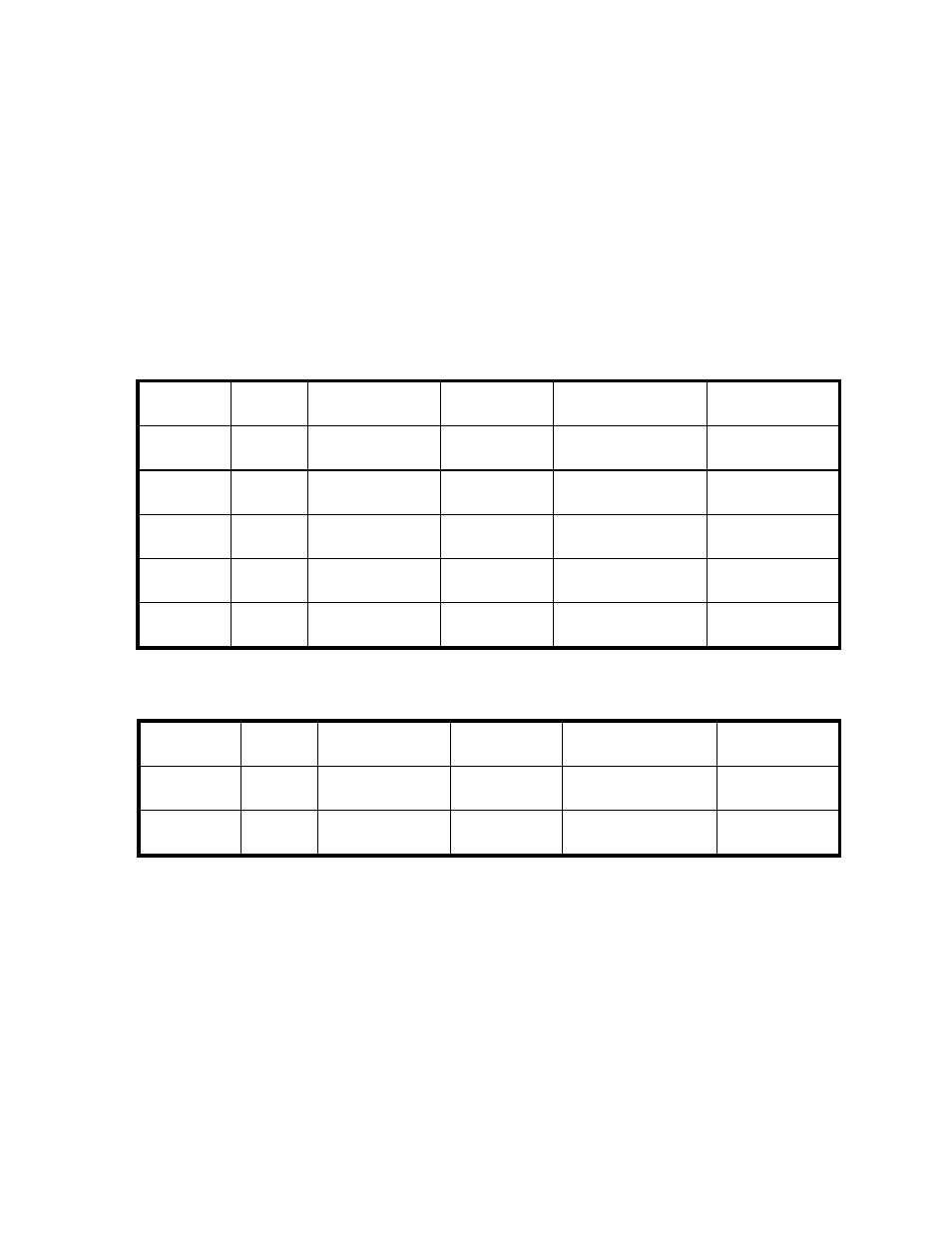

on the Tachometer to that listed on the Blade Speed Chart shown below.

See Section B. Engine subsection 6. Engine Speed (page 16 to 17)

for more details on changing the engine speed

Straight Drive 31 & 61 HP:

Blade

Diameter

Engine

RPM

Engine Pulley

Diameter

Blade

Shaft RPM

Blade Shaft

Pulley Diameter

Blade Collar

Diameter

14”

(356mm)

2800 4.0

inch

(102 mm)

2560

4.38 inch

(111mm)

4.5 inch

(114mm)

20”

(508mm)

2700 4.0

inch

(102 mm)

2469

4.38 inch

(111mm)

4.5 inch

(114mm)

26”

(660mm)

2400 4.0

inch

(102 mm)

2194

4.38 inch

(111mm)

4.5 inch

(114mm)

30”

(762mm)

2600 4.0

inch

(102 mm)

1340 7

inch

(178mm)

6 inch

(152mm)

36”

(914mm)

2500 4.0

inch

(102 mm)

1290 7

inch

(178mm)

6 inch

(152mm)

Jackshaft Drive 61HP:

Blade

Diameter

Engine

RPM

Engine Pulley

Diameter

Blade

Shaft RPM

Blade Shaft

Pulley Diameter

Blade Collar

Diameter

42 inch

(1067mm) 2800

4.0 inch

(102 mm)

890

6 inch

(152mm)

8 inch

(203mm)

48 inch

(1219mm) 2500

4.0 inch

(102 mm)

800

6 inch

(152mm)

8 inch

(203mm)

10. Slowly lower the blade by moving the Raise/Lower Switch forward. For

more details on controlling the lowering speed see section Hydraulic

System (page xx). Do not force the blade in to the cut!! Step Cutting

provides the best performance (fastest cut and longest blade life) for

additional information see section E. Cutting Techniques (page 22).

Never saw deeper than 4” per pass as deeper passes will shorten the

blade life and places higher stresses on the saw. Never twist, rotate, or

bend the blade while in the cut. Do not attempt to cut in a circle or arc as

the blade may be damaged.