Figure 8. standard duct connector in- stalled, Table 3. duct connector sizes – Nordyne Downflow Direct Vent Forced Air Gas Oil Furnaces SERIES M1B User Manual

Page 9

9

FLOOR CUT-OUT

FOR STANDARD

DUCT CONNECTORS

CL

CL

C

L

24"

23 1/4"

21 3/4"

14 1/2"

2 1/4"

2 3/4"

20"

CUT-OUT FOR

OPTIONAL

COOLING COIL

REAR WALL OF CLOSET OR ALCOVE

1 3/4"

2"

3/4"

CL

CL

CL

10"

CL

FURNACE OUTLINE

14 1/2"

ALT FUEL-LINE

ENTRY 1 1/4" Dia.

FURNACE

OUTER

DOOR

FUEL

LINE

1 3/4"

3/4"

1 7/8"

2 7/8"

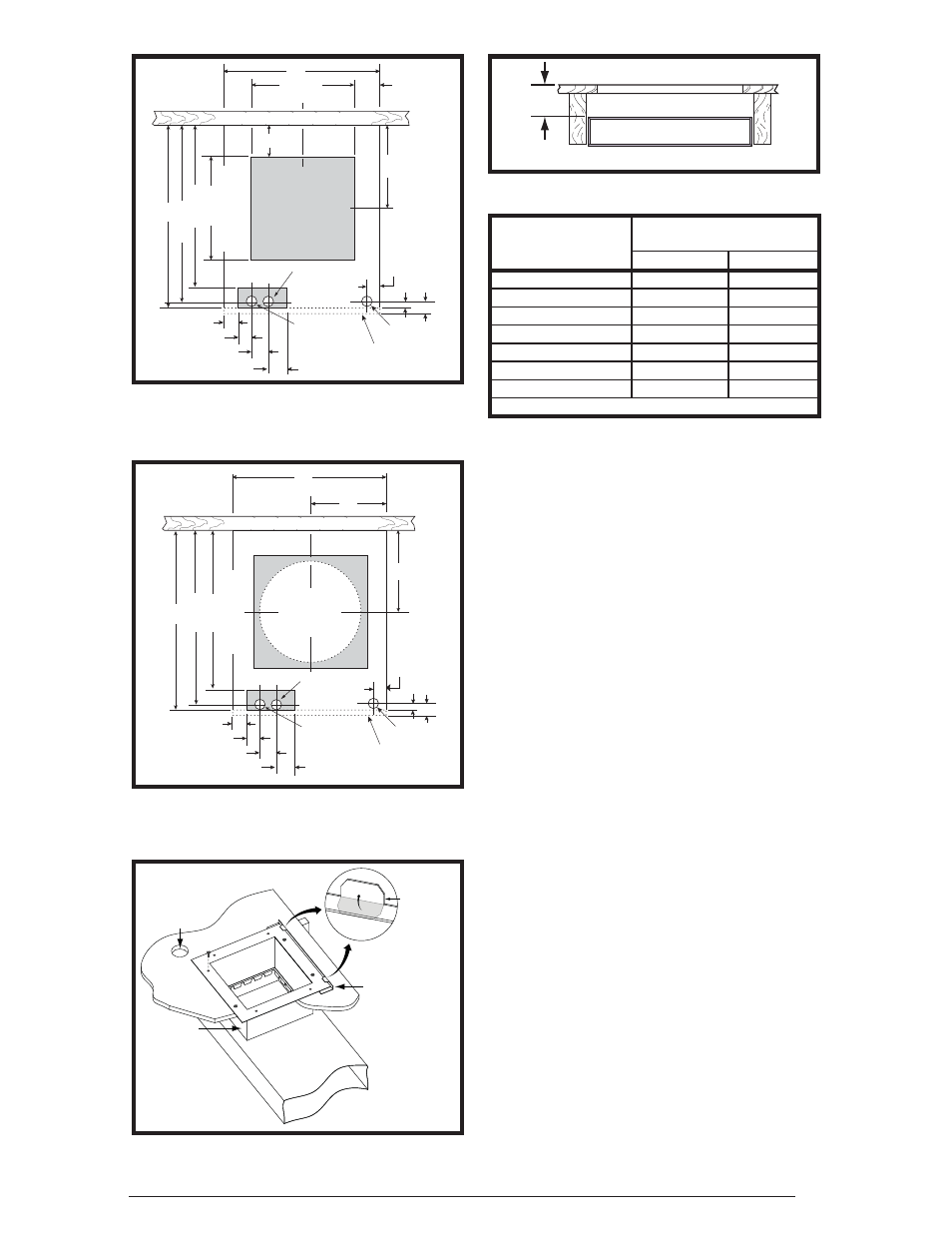

Figure 6. Cut-Out Dimensions for

Standard Duct Connectors

FLOOR

CUT-OUT FOR

ROUND DUCT

(14 1/4” DIAMETER)

CL

CL

CL

CL

24"

23 1/4"

21 3/4"

20"

CUT-OUT FOR

OPTIONAL

COOLING COIL

ALT FUEL-LINE

ENTRY 1 1/4" Dia.

FURNACE

OUTER

DOOR

REAR WALL OF CLOSET OR ALCOVE

FUEL

LINE

1 3/4"

2"

3/4"

CL

CL

10"

FURNACE OUTLINE

1 3/4"

10"

3/4"

1 7/8"

2 7/8"

CL

Figure 7. Cut-Out Dimensions for

Round Duct Connectors

Bend tabs

up 90°

Mounting Plate

Duct

Connector

Connector

Tabs

Supply

Air Duct

Hole for

Gas Line

Wood Floor

Figure 8. Standard Duct Connector In-

stalled

If Floor Cavity

“X” is:

Duct Connector

Type & Part Number

Standard Duct

Round Duct

7/8” / (22)

901987A

904008

2” / (51)

901988A

904009

4-1/4” / (108)

901989A

904010

6-1/4” / (159)

901990A

904011

8-1/4” / (210)

901991A

904012

10-1/4” / (260)

901992A

904013

12-1/4” / (311)

901993A

904014

Note: Dimensions shown as Inches / (Millimeter)

Table 3. Duct Connector Sizes

“X”

FLOOR OPENING

FLOOR

CAVITY

SUPPLY AIR DUCT

Figure 9. Floor Cavity

Standard Duct Connector Installation

The standard duct connector is designed for use

on ducts 12” in width. However ducts narrower

than 12” may not allow suffi cient clearances

for this type of installation. For an alternate

installation method, see page 10.

1. Center the duct connector in the fl oor opening

with bottom tabs resting on top of the supply

air duct.

2. Mark the cut-out area on the supply air duct by

tracing around the connector tabs (Figure 8) of the

duct connector.

3. Remove the duct connector and cut out the

marked area of the supply air duct 1/4” larger

the actual cutout drawn.

4. Install the duct connector back in the fl oor

opening with the bottom tabs extending into

the supply air duct.

5. Install the mounting plate (Figure 8) under

the back side of the duct connector. Align the

screw holes in both components.

6. Secure the duct connector and the mounting

plate to the wood fl oor with appropriate size

screws.

7. Bend the connector tabs on the bottom of

the duct connector upwards and as tight as

possible against the supply air duct.

8. Bend both tabs on the mounting plate up 90°.

See Figure 10, (page 10)

9. Seal all connections with industrial grade

sealing tape or liquid sealant.

NOTE: Requirements for sealing ductwork

vary from region to region. Consult with local

codes for requirements specifi c to your area.