Caution – Nordyne Downflow Direct Vent Forced Air Gas Oil Furnaces SERIES M1B User Manual

Page 23

23

Table 7. Factory Combustion Air Settings

Model

Nat. Gas

LP Gas

Oil

66,000

3.5

3.5

3.5

86,000

5.3

6

5

Combustion Air

In order for the fl ame to burn effi ciently, it must

receive adequate combustion air. The amount

of combustion air required varies according to

altitude, actual B.T.U. content of the fuel, gas

pressure, conversion to another gas and other

factors. The burner fl ame should be observed

and any necessary adjustments made before

the furnace is placed into service. See Table 7

for Factory Air settings.

CAUTION:

• Combustion air adjustment must

be made only by a qualifi ed tech-

nician. Improper air adjustment

may cause unsafe operation, ex-

plosion and/or fi re asphyxiation.

• If the input to the furnace is too

great because of excessive gas

pressure, wrong size nozzle or

orifi ce, high altitude, etc., the

burner fl ame will be sooty and

can produce carbon monoxide,

which could result in unsafe

operation, explosion and/or fi re

or asphyxiation.

The Smoke should be N0. 0 on the Bacharach

Scale, and 0 to 0.02 negative draft over fi re.

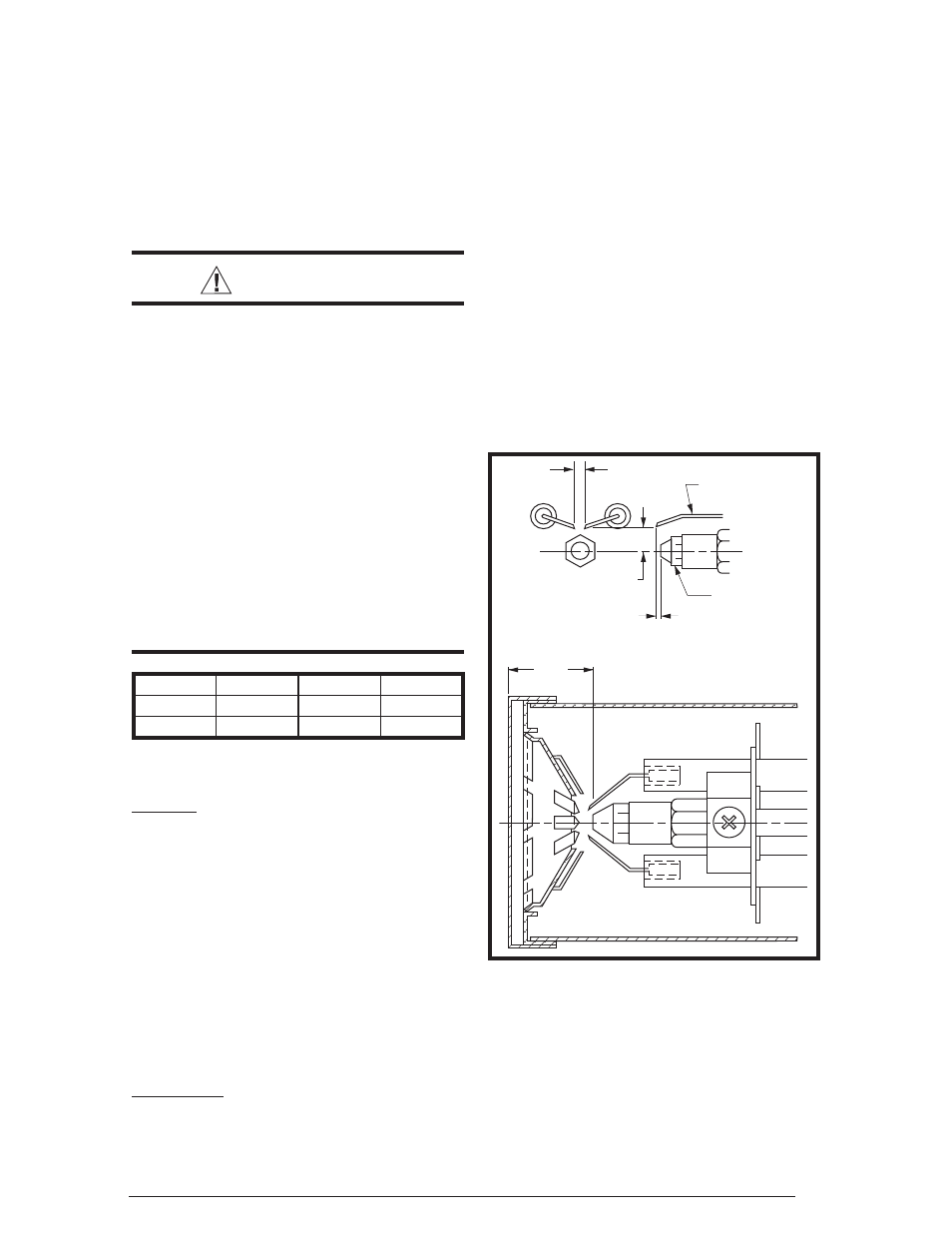

Electrode Setting (Oil Gun Only)

Poor ignition of the oil spray may result if the

electrodes are not adjusted as shown in Figure

34. Do not permit any electrodes to be grounded

to any surface.

S w i t ch i n g I g n i t i o n C o n t ro l b e t w e e n

Interrupted and Intermittent Duty (Oil Gun

Only)

Honeywell and Beckett oil primary controls can

be switched between interrupted and intermittent

ignition control. To switch from interrupted duty

(Factory set) to intermittent duty, remove the blue

wire from the quick-connect terminal. Attach the

burner motor and igniter wire to the burner motor

(orange) control terminal by splicing or adding

tab adapters. Seal and isolate any bare wires.

5/32” GAP

ELECTRODE

NOZZLE

0-1/16”

5/16” ABOVE CL

1 1/8”

Figure 34. Oil Gun electrode Position

Gas Gun

Combustion air box adjustment is made to the

main burner by loosening the two lock nuts on

the plastic air shutter, located on the left side of

the burner blower housing. Air shutter adjustment

line is located on the same side of the blower

housing. Turn the plastic shutter to a smaller

number (counter clockwise) for less air to a larger

number (clockwise) for more air. Gently tighten

the lock nuts after completing the adjustment. For

best results, use instrument to measure between

8 - 9% CO

2

, after the combustion air has been

adjusted. Note: Do not over-tighten the lock nuts.

This may damage the plastic air shutter.

Oil Gun Only

It is recommended that the CO

2

and Smoke levels

be measured for maximum performance. CO

2

readings should be 10 - 11% for 66,000 BTUH

furnaces and 12 - 13% for 86,000 BTUH furnaces.