Operational controls and adjustments, Start/stop controls, Locking switch in the “off” position – Porter-Cable 70-200 User Manual

Page 15: Spindle speeds, Changing spindle speeds and belt tension, Operation

15

OPERATIONAL CONTROLS AND ADJUSTMENTS

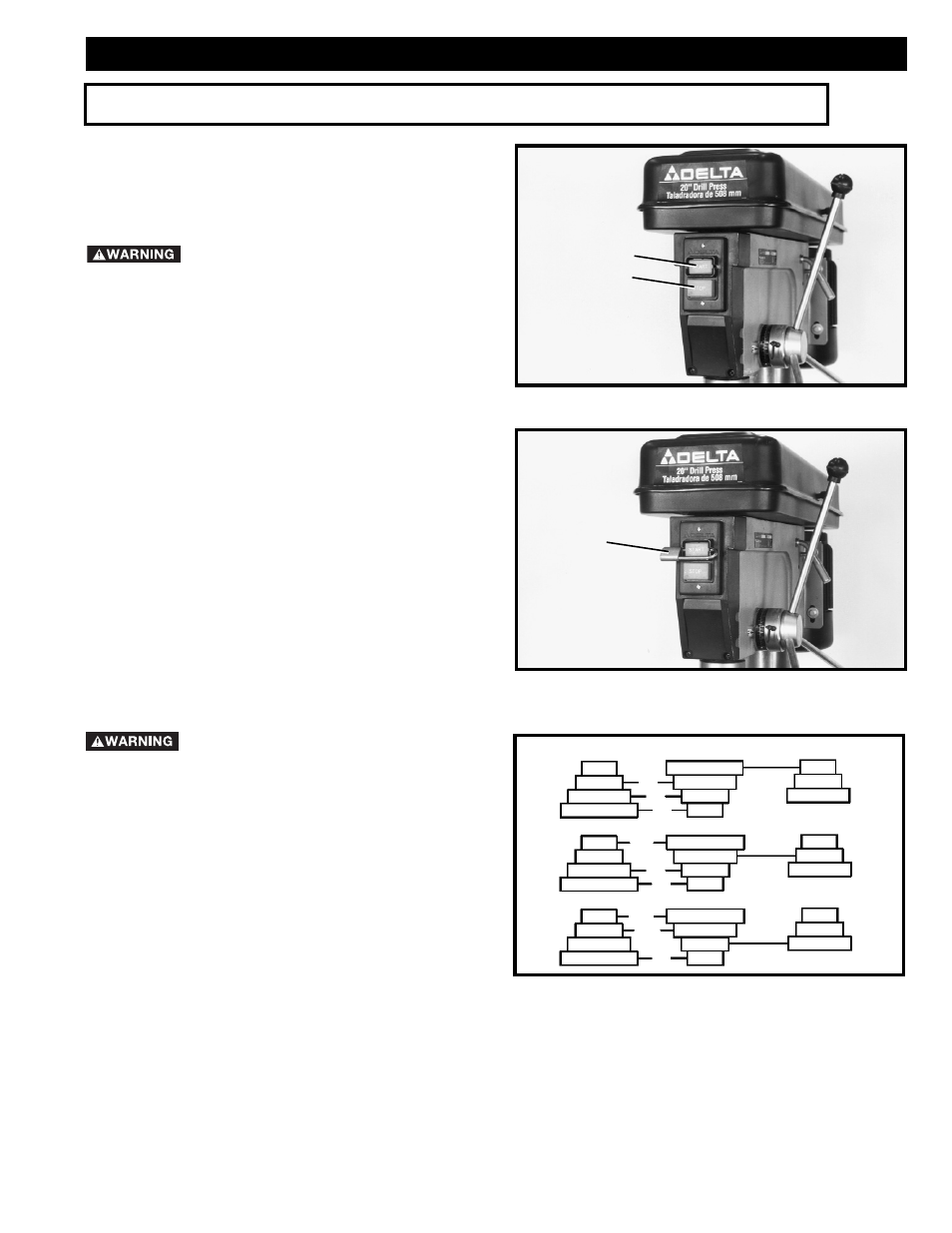

Fig. 23

START/STOP CONTROLS

The start/stop buttons are located on the front of the drill

press head. To start the machine, press the start button (A)

Fig. 23, and to stop the machine, press the stop button (B).

MAKE SURE THAT THE BUTTON IS IN

THE “STOP” POSITION BEFORE PLUGGING IN THE

POWER CORD. IN THE EVENT OF A POWER FAILURE,

PUSH THE “STOP” BUTTON. AN ACCIDENTAL START-

UP CAN CAUSE INJURY.

LOCKING SWITCH IN

THE “OFF” POSITION

IMPORTANT: When the machine is not in use, the

“STOP” button should be locked to prevent

unauthorized use, using a padlock (C) Fig. 24, with

3/16

″ diameter shackle.

Fig. 24

SPINDLE SPEEDS

Nine spindle speeds of 150, 260, 300, 440, 490, 540,

1150, 1550, and 2200 RPM are available with the 20

″

Drill Press. Fig. 25, illustrates which steps of the pulleys

the belts must be placed to obtain the nine speeds

available.

A

B

C

Fig. 25

SPINDLE

CENTER

MOTOR

440

300

150

1150

540

260

2200

1550

490

CHANGING SPINDLE

SPEEDS AND BELT TENSION

DISCONNECT MACHINE FROM THE

POWER SOURCE.

1.

Lift up the belt and pulley guard (A) Fig. 26.

2.

Loosen the two lock knobs, one of which is shown

at (B) Fig. 26. The remaining lock knob is located on the

opposite side of the head casting.

3.

Release belt tension by moving tension lever (C)

Fig. 26, forward.

4.

Position the two belts (D) Fig. 26, on the desired

steps of the motor, center and spindle pulleys. To raise

or lower motor pulley (E) Fig. 26, use the 4mm hex

wrench and loosen set screw (F), located under the

pulley. After pulley is positioned, re-tighten set screw (F).

OPERATION