Warning – PB Heat Gas Boiler User Manual

Page 20

18

3. To check the gas supply pressure on the gas valve:

a. Turn off the power at the service switch.

b. Turn off the gas shutoff valve.

c. Using a flat screwdriver, turn the screw inside the

inlet pressure tap fitting (see figure 4.4 and 4.5)

one turn counterclockwise.

d. Attach the manometer tube to the pressure tap

fitting.

e. Open the gas shutoff valve and start the boiler.

f.

Read and record the gas pressure while the boiler

is firing.

g. Turn off the boiler and gas shutoff valve

h. Remove the manometer tube from the pressure

tap fitting and turn the screw to close the internal

valve.

i.

Turn on the gas shutoff valve and boiler service

switch.

4. All gas piping must be leak tested prior to placing the

boiler in operation.

a. If the leak test pressure requirement is higher

than the maximum inlet pressure noted in Table

4.4, the boiler must be isolated from the gas

supply piping system.

b. If the gas valve is exposed to pressures exceeding

13.5" of water, the gas valve must be replaced.

5. Install the boiler such that the gas ignition system

components are protected from water (dripping,

spraying, rain, etc) during operation and service

(circulator replacement, condensate trap cleanout,

and control replacement, etc).

E. MAIN GAS VALVE - OPERATION

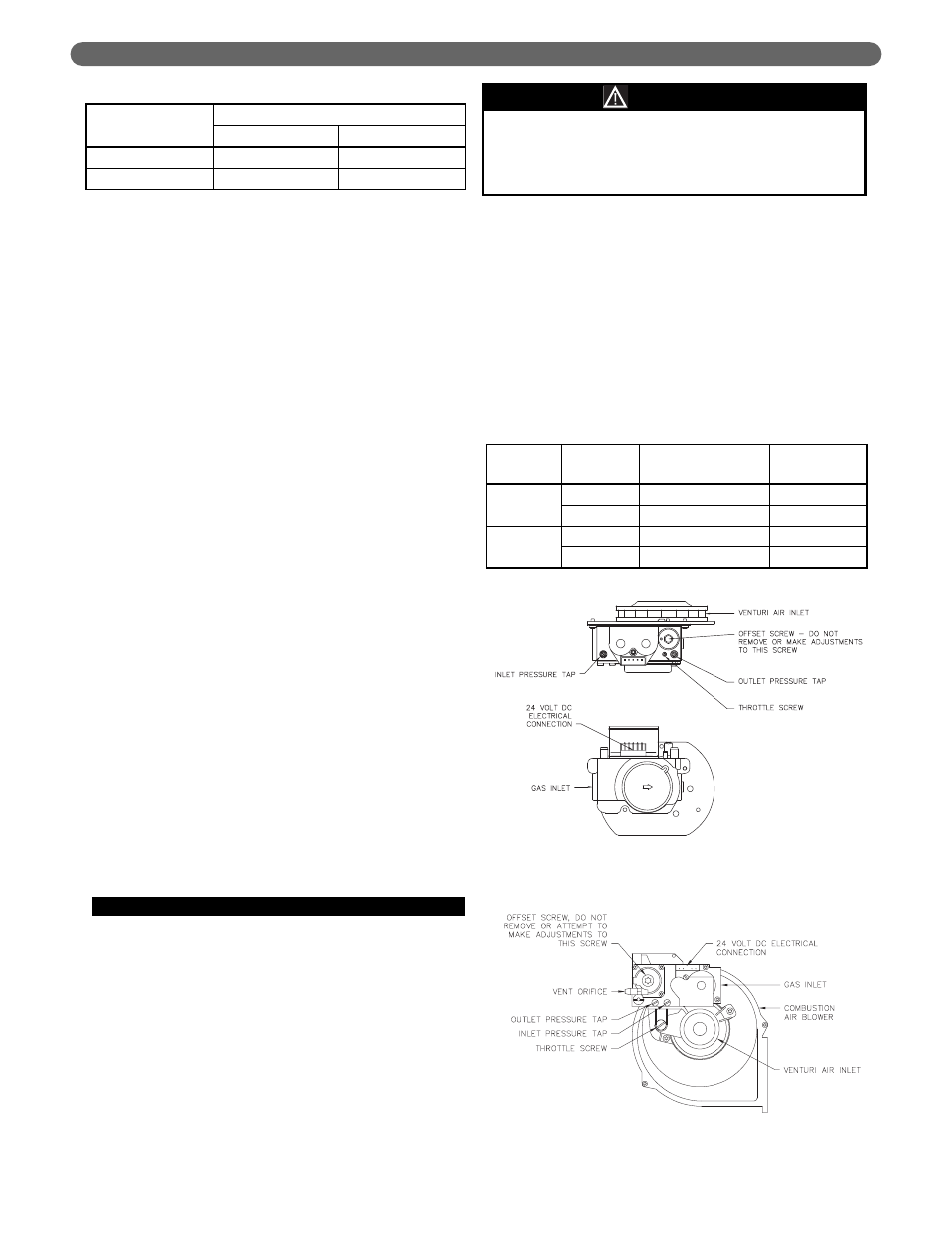

1. Figure 4.4 shows an illustration of the gas valve/venturi

assembly for the Pinnacle PI-T50 and PI-T80 and

Figure 4.5 shows an illustration of the gas valve/venturi

assembly for the PI-80, PI-140, and PI-199.

a. The throttle screw on either of these valves

should not be adjusted without a means to

measure carbon monoxide (CO) and carbon

dioxide (CO²) emissions.

b. For both gas valve arrangements, turning the

throttle screw clockwise will decrease the gas flow

(decreasing CO²) and turning it counterclockwise

will increase the gas flow (increasing CO²).

c. The recommended CO² settings are given in

Table 4.5. In no case should the boiler be

allowed to operate with CO emissions in excess

of 150 ppm.

2. Refer to Section 5, Venting for information on

obtaining vent samples from this boiler.

GAS PIPING

Do not adjust the throttle screw without monitoring

the carbon dioxide (CO²) and carbon monoxide (CO)

in the vent pipe. Vent CO emissions above 400 ppm

are in excess of most safety standards.

WARNING

Gas

Type

Pressure (inches of water)

Minimum

Maximum

Natural

3.7

13.5

LP

3.7

13.5

Table 4.4: Maximum and Minimum Fuel Pressure

Gas Type

Firing

Rate

Vent CO²

Vent CO

Natural

Low

8-1/2% to 9-1/2%

< 50 ppm

High

8-1/2% to 9-1/2%

< 100 ppm

LP

Low

9-1/2% to 10-1/2%

< 50 ppm

High

9-1/2% to 10-1/2%

< 100 ppm

Table 4.5: Recommended Vent CO² Settings

Figure 4.4: Gas Valve/Venturi PI-T50/PI-T80

Figure 4.5: Gas Valve/Venturi PI-80, PI-140, PI-199